Method for rolling wide thin plates of wide and thick plate rolling machine

A plate rolling mill and thin plate technology, applied in rolling mill control devices, metal rolling, metal rolling, etc., can solve problems such as plate shape and performance instability, and achieve the effects of high pass rate, uniform performance, and optimized rolling procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

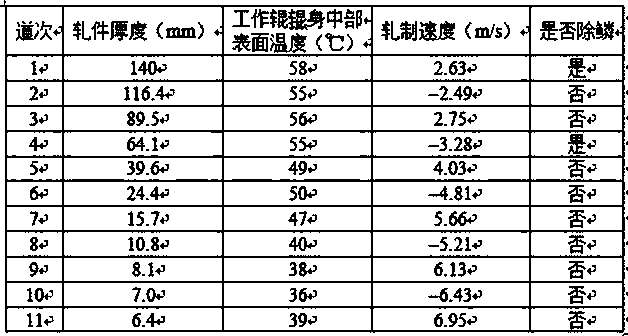

[0019] The rolling raw material is continuous casting slab with a section of 260mm×2270mm, and the steel type is CCS E; the target thickness of the rolled steel plate is 6mm, and the actual average thickness is 6.1mm; the target width of the steel plate is 3160mm; the length of the rolled mother plate is about 38280mm, cut 3 sub-plates, the length of the sub-plates is 12000mm; the key rolling process of the steel plate:

[0020] (a) Roll the continuous casting slab to a billet with a thickness of 140mm, and carry out widening and rolling during the billeting process. After widening, the width of the billet is about 3280mm, so that the trimming amount of the finished steel plate is about 120mm; and used during the widening process In the PVPC mode, set the proportion of the length of the PVPC inner zone to 20%, the proportion of the length of the PVPC outer zone to 80%, and the PVPC cumulative depth of the widening pass to be 4mm;

[0021] (b) Adopt a walking beam heating furna...

Embodiment 2

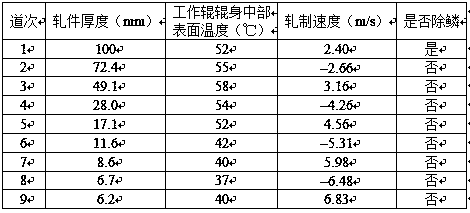

[0031] The raw material for rolling is a continuous casting slab with a section of 180mm×2070mm, and the steel type is Q370qE; the target thickness of the rolled steel plate is 6mm, and the actual average thickness is 5.8mm; the target width of the steel plate is 2610mm; the length of the rolled mother plate is about 32100mm, cut into 2 sub-plates, the length of the sub-plates is 14900mm; the key rolling process of the steel plate:

[0032] (a) Roll the continuous casting slab to a billet with a thickness of 100mm, and carry out widening and rolling during the billeting process. After widening, the width of the billet is about 2700mm, so that the trimming amount of the finished steel plate is about 90mm; and used during the widening process In the PVPC mode, set the proportion of the length of the PVPC inner zone to 15%, the proportion of the length of the PVPC outer zone to 90%, and the PVPC cumulative depth of the widening pass to be 3mm;

[0033] (b) A walking beam heating ...

Embodiment 3

[0043] The rolling raw material is continuous casting slab with a section of 220mm×2270mm, and the steel type is Q460GJE; the target thickness of the rolled steel plate is 6mm, and the actual average thickness is 6.3mm; the target width of the steel plate is 3380mm; the length of the rolled mother plate is about 33100mm, cut into 3 sub-plates, the length of the sub-plates is 10200mm; the key rolling process of the steel plate:

[0044] (a) Roll the continuous casting slab to a billet with a thickness of 120mm, and carry out widening and rolling during the billeting process. After widening, the width of the billet is about 3480mm, so that the trimming amount of the finished steel plate is about 100mm; and used during the widening process In the PVPC mode, set the proportion of the length of the PVPC inner zone to 25%, the proportion of the length of the PVPC outer zone to 75%, and the PVPC cumulative depth of the widening pass to be 5mm;

[0045] (b) Adopt a walking beam heatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com