220 kV crosslinkable polyethylene insulating material with low by-product content and preparation method of 220 kV crosslinkable polyethylene insulating material

A cross-linked polyethylene, 220kv technology, applied in the direction of insulators, organic insulators, plastic/resin/wax insulators, etc., can solve by-products can not be discharged in time, can not meet the design requirements of 220kV cable insulation materials, pinholes and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

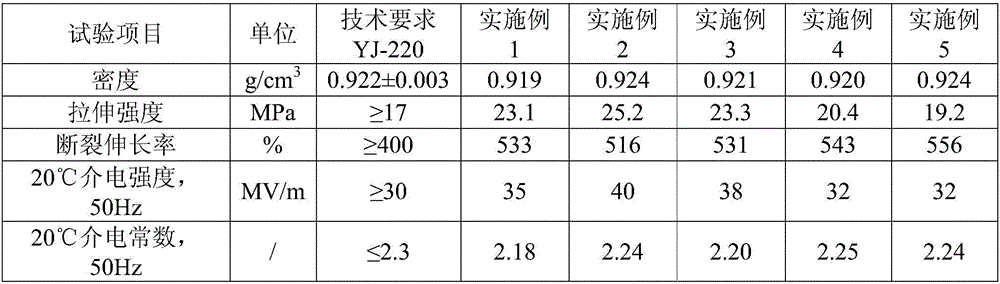

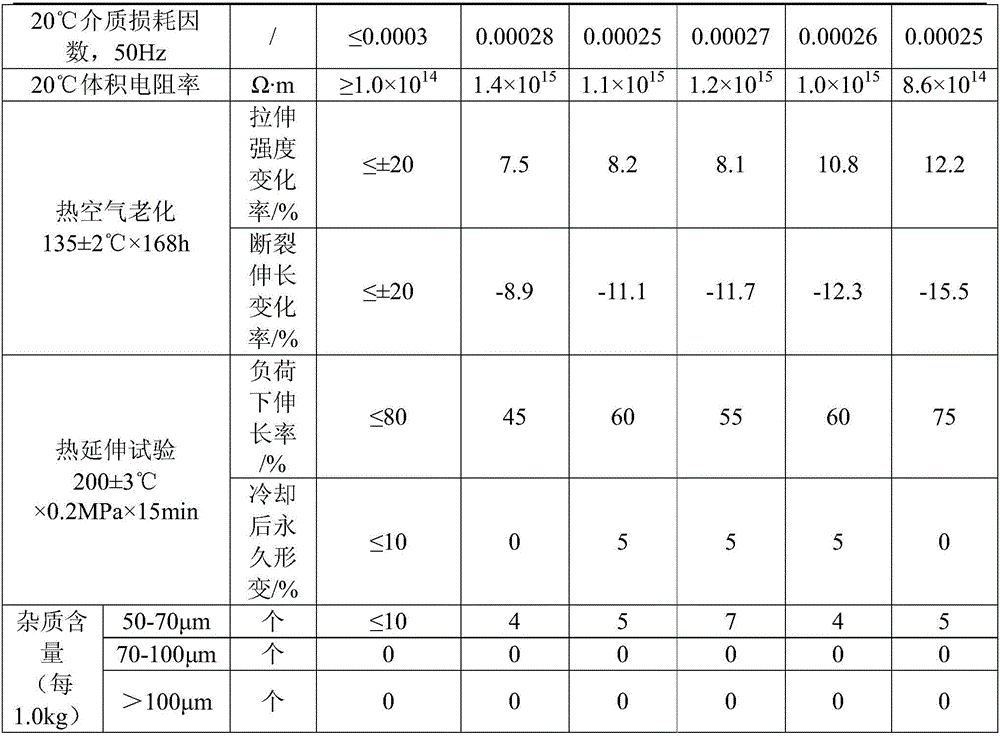

Examples

Embodiment 1

[0019] This embodiment provides a 220kV cross-linkable polyethylene insulating material with low by-products, including the following raw material components:

[0020] 100 parts of low-density polyethylene (density 0.916g / cm 3 , melt flow index is 1.8g / 10min),

[0021] 0.5 parts of 4,4'-thiobis(6-tert-butyl-3-methylphenol),

[0022] 1.0 parts of dicumyl peroxide,

[0023] Liquid polybutadiene (viscosity is 1100mPas) 3.0 parts;

[0024] The above 220kV cross-linkable polyethylene insulating material with low by-products is prepared by the following method: in a closed and purified production environment, low-density polyethylene, antioxidant, cross-linking agent and cross-linking accelerator are mixed according to the formula After mixing, homogenizing, filtering, and removing volatile matter, cooling and dicing, and clean packaging, a 220kV cross-linkable polyethylene insulating material with low by-products can be obtained (the steps of mixing, homogenizing, and filtering ...

Embodiment 2

[0026] This example provides a 220kV cross-linkable polyethylene insulating material with low by-products, the preparation method of which is the same as that in Example 1, except that it includes the following raw material components:

[0027] 100 parts of low-density polyethylene (density 0.925g / cm 3 , melt flow index is 2.5g / 10min),

[0028] 0.8 parts of 3,5-bis(1,1-dimethylethyl)-4-hydroxyphenylpropionic acid thiodi-2,1-ethylene glycol ester,

[0029] 0.5 parts of benzoyl peroxide,

[0030] Liquid polyisoprene (viscosity of 900mPas) 2 parts.

Embodiment 3

[0032] This example provides a 220kV cross-linkable polyethylene insulating material with low by-products, the preparation method of which is the same as that in Example 1, except that it includes the following raw material components:

[0033] 100 parts of low-density polyethylene (density 0.922g / cm 3 , melt flow index is 2.3g / 10min),

[0034] 0.8 parts of 3,5-bis(1,1-dimethylethyl)-4-hydroxyphenylpropionic acid thiodi-2,1-ethylene glycol ester,

[0035] 0.5 parts of benzoyl peroxide,

[0036] 1.8 parts of liquid polytriallyl isocyanurate (viscosity is 700mPas).

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com