Extruding machine and method of utilizing extruding machine to manufacture large-diameter thick-wall seamless copper pipe

A technology for extrusion machines and copper tubes, applied in the direction of metal extrusion, metal extrusion dies, manufacturing tools, etc., to achieve the effects of long service life, improved product quality, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

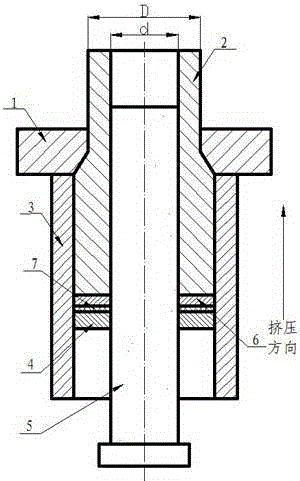

Method used

Image

Examples

Embodiment 1

[0030] Produce Φ1020×30×6000mm copper (Z2) large-diameter thick-walled seamless copper tubes.

[0031] 1 red copper (Z2) billet weight 11.5 tons;

[0032] 2 The copper ingots are transferred to the natural gas heating furnace, and the temperature is raised to 850°C as soon as possible, and the temperature is kept for 6 hours; the heated and heat-preserved copper billets are transferred to the upsetting cylinder, and the upsetting steel is used to upset the copper ingots at 90mm / s, and Under the pressure drop of 15,000 tons, the copper ingot was kept under pressure for 45s to improve the material structure;

[0033] 3 After upsetting the copper ingot with a 15,000-ton billet making machine, use a Φ940 perforating needle to perforate the billet along the axis of the copper ingot at the original station. The perforation speed of the perforation needle is 90mm / s. The blank surface is treated without visual defects.

[0034] 4 Use an electronic scale to take MoS by weight ratio ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com