Recoiling withdrawal and straightening method for saving yield strength of cold-rolled strip steel lower than requirement

A yield strength and cold-rolled strip technology, applied in metal rolling, metal rolling, metal processing equipment, etc., can solve the problem of lowering the yield strength of cold-rolled finished products, and achieve the goal of reducing the loss of steel mills and improving the efficiency of steel grades. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

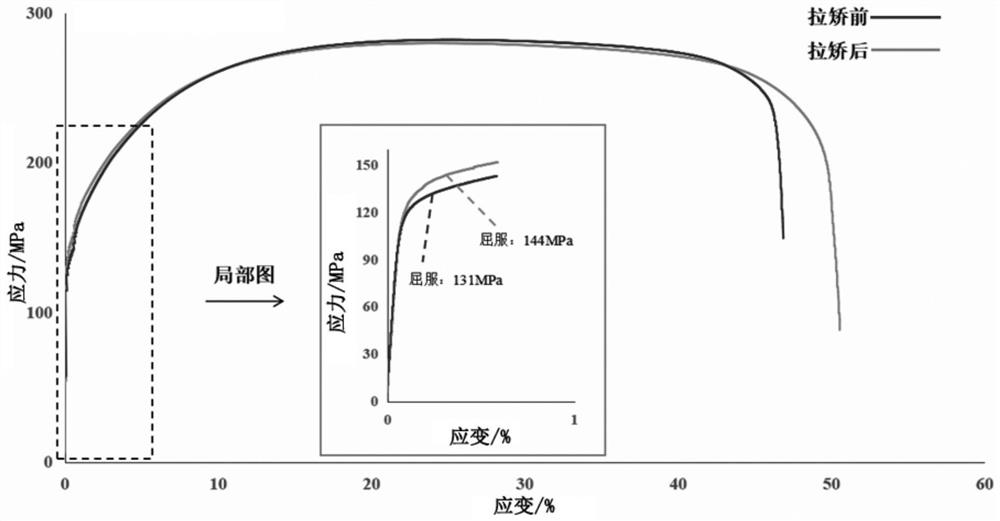

Embodiment 1

[0032] The cold-rolled finished coil with the grade of DC03-X, the coil number is C21069564C10C200, and its yield strength is less than the lower limit of the standard.

[0033] Table 1 Example 1 strip steel mechanical properties and dimensions before straightening

[0034] Yield strength / MPa Tensile strength / MPa Extend A80 / % Thickness / mm width / mm 131 280 47.8 0.787 1322.6

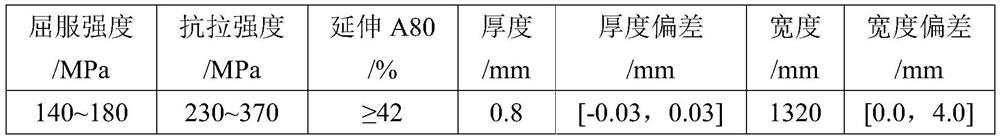

[0035] Table 2 DC03-X mechanical properties and size requirements

[0036]

[0037] The cold-rolled finished coil is re-rolled and straightened by using a two-bend, two-straightening and straightening machine. The specific steps are as follows:

[0038] Set the unwinding tension to 20kN, the rewinding tension to 38kN, the tension and straightening tension to 98N, the yield value to be 125MPa, and the elongation to be 0.6%.

[0039] The inlet is uncoiled, the head of the coil and the tail of the upper coil are welded, and the strip speed is controlled to be 10m / min when th...

Embodiment 2

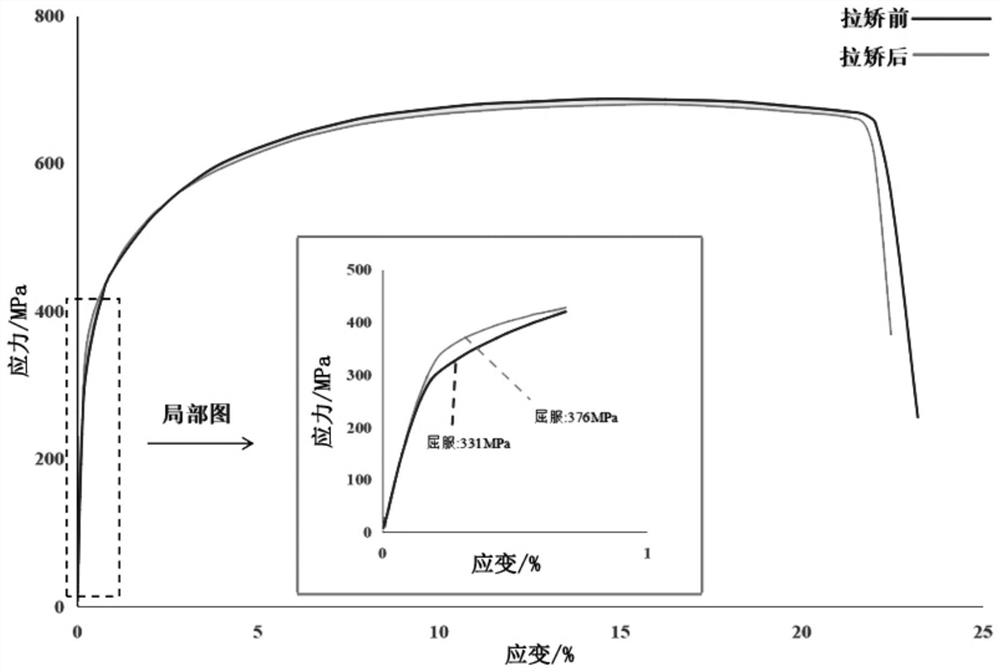

[0044] The cold-rolled finished coil with the grade of CR340 / 590DP, the coil number is 2108806710C400, and its yield strength is less than the lower limit of the standard. The actual performance and size of the product are shown in Table 4. The mechanical properties and orders specified in the national standard (GB / T 20564.2-2017) The agreed size requirements are shown in Table 5.

[0045]Table 4 embodiment 2 strip steel mechanical properties and dimensions before straightening

[0046] Yield strength / MPa Tensile strength / MPa Extend A80 / % n value Thickness / mm width / mm 331 683 22.5 0.151 1.516 1362.8

[0047] Table 5 Mechanical properties and size requirements of CR340 / 590DP

[0048]

[0049] The cold-rolled finished coil is re-rolled and straightened by a two-bend, two-straightening and straightening machine. The specific steps are as follows:

[0050] Set the unwinding tension to 35kN, the rewinding tension to 55kN, the tension and straig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com