Precise composite phosphating tank solution and phosphating technology thereof

A phosphating tank and precision technology, applied in the coating process of metal materials, etc., can solve the problems of reducing the surface roughness of the workpiece, difficulty in film formation, uneven film layer, etc., and achieve the effect of simple formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

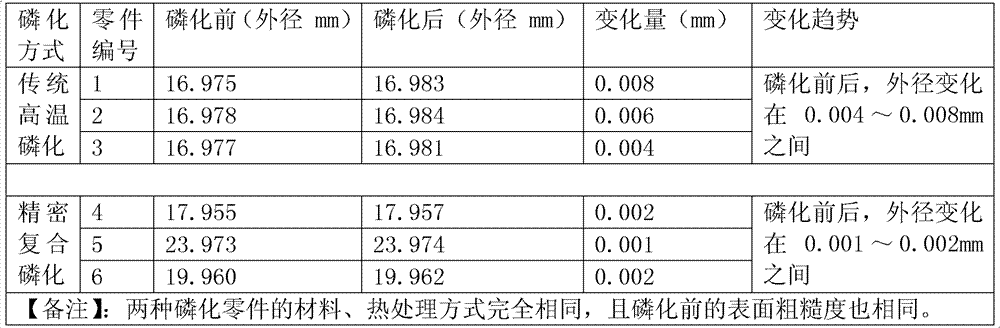

Examples

Embodiment 1

[0025] Example 1. A precision compound phosphating bath solution, its composition is phosphoric acid, manganese dihydrogen phosphate and phosphating agent, specifically, commercially available phosphoric acid 6ml / l, ferromanganese phosphate 29g / l, phosphating agent 31g / l. The composition of the phosphating agent is calcium nitrate, zinc nitrate and sodium fluoride, and the mass ratio is 17:11:1 in sequence.

[0026] The phosphating process using the above-mentioned precision composite phosphating bath solution includes the following steps: degreasing, activating, neutralizing, and phosphating. Wherein: the degreasing process is specifically to clean the parts with an aqueous cleaning agent or an organic solvent, and then use electrolytic degreasing to completely remove the oil on the surface of the workpiece; the activation process specifically is to clean the workpiece after degreasing Carry out weak corrosion treatment in the hydrochloric acid aqueous solution that volume r...

Embodiment 2

[0027] Example 2. A precision composite phosphating bath solution, the composition of which is phosphoric acid, ferromanganese phosphate and phosphating agent, specifically, commercially available phosphoric acid 7ml / l, ferromanganese phosphate 28g / l, and phosphating agent 31g / l. The composition of the phosphating agent is calcium nitrate, zinc nitrate and sodium fluoride, and the mass ratio is 15:10:1.5 in turn. Commercially available phosphoric acid is purchased from the market, and commercially available phosphoric acid has a specified concentration range.

[0028] The phosphating process using the above-mentioned precision composite phosphating bath solution includes the following steps: degreasing, activating, neutralizing, and phosphating. Wherein: the degreasing process is specifically to clean the parts with an aqueous cleaning agent or an organic solvent, and then use electrolytic degreasing to completely remove the oil on the surface of the workpiece; the activation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com