Precipitation strengthening high-carbon austenitic heat-resistance steel and preparation method thereof

A technology for austenitic heat-resistant steel and precipitation strengthening, applied in the field of precipitation-strengthening high-carbon austenitic heat-resistant steel and its preparation, can solve the problems of adverse effects on alloy properties, limited effect of alloy structure, etc., and achieve carbide growth rate The effect of slowing down, eliminating eutectic carbides and stabilizing the structure and properties of alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

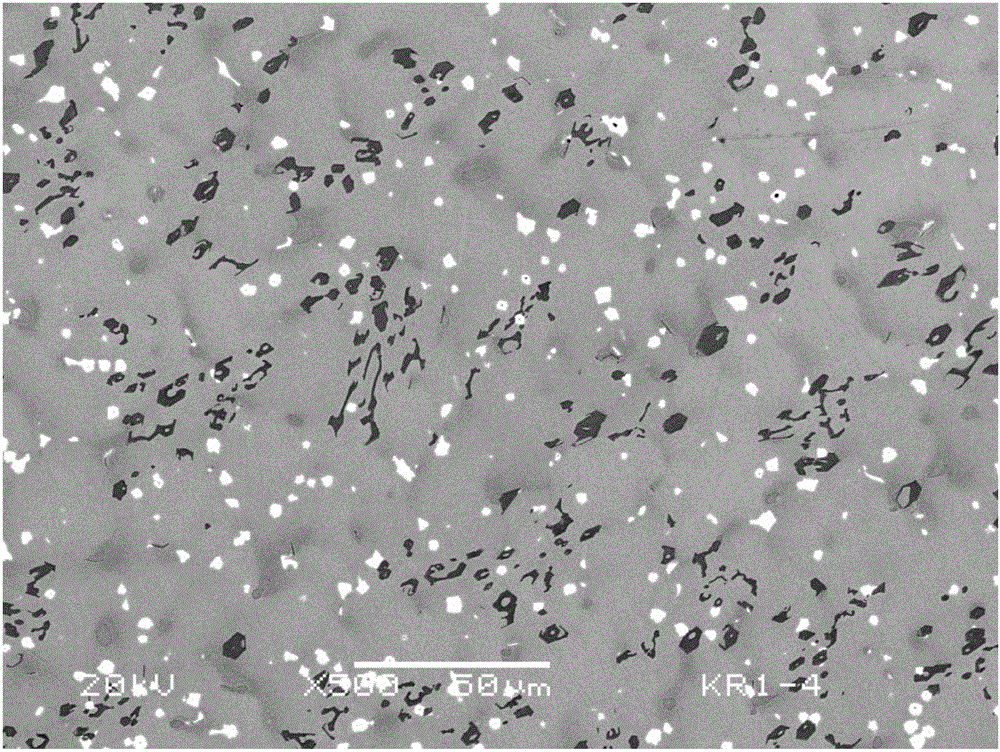

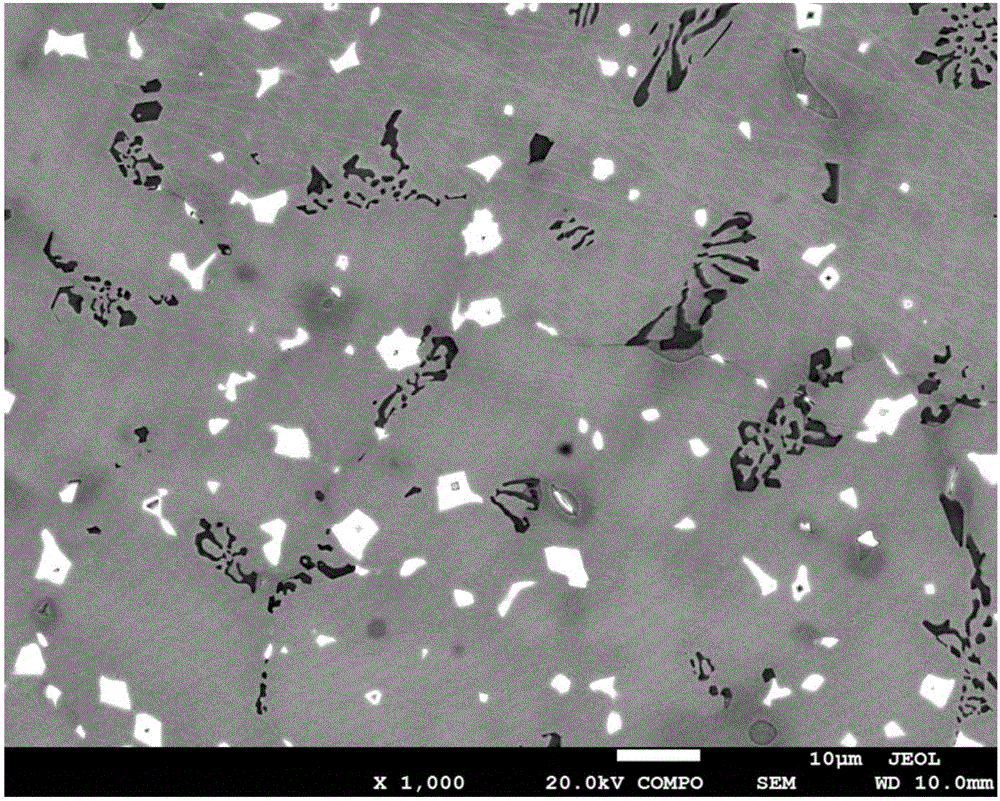

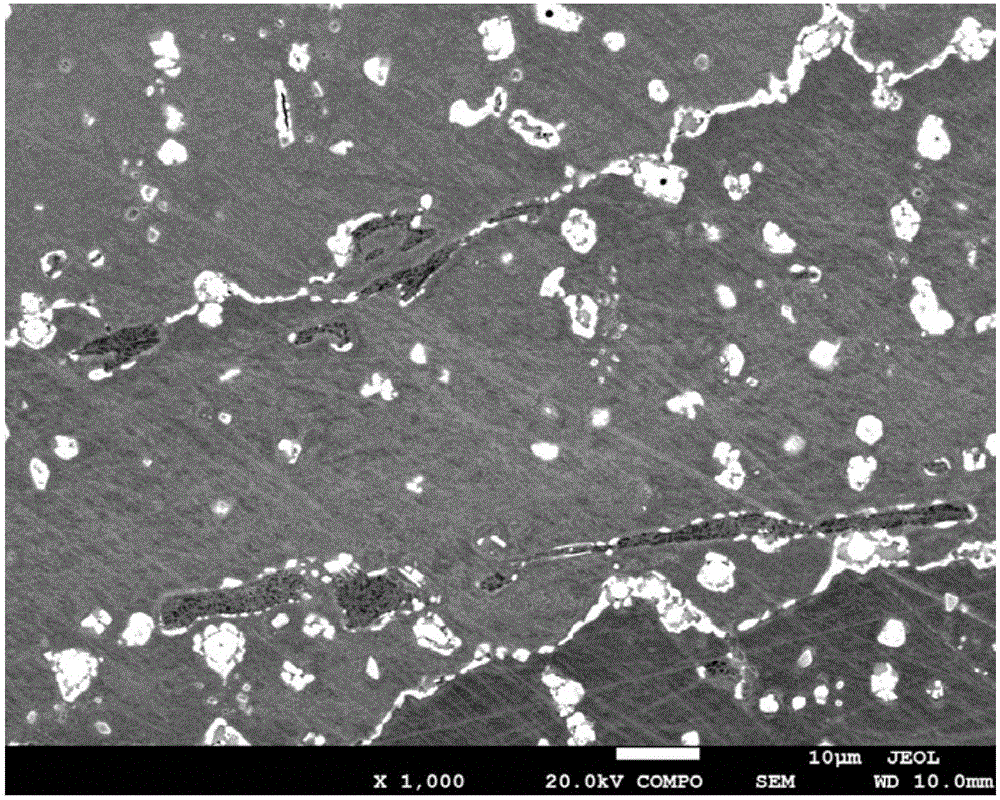

Image

Examples

Embodiment 1

[0025] The precipitation-strengthened high-carbon austenitic heat-resistant steel of this embodiment, by mass percentage, includes: C: 0.7%, Cr: 25%, Ni: 45%, Mn: 1.0%, Si: 2.5%, Nb: 1.0 %, W: 5.0%, Ti: 1.0%, and the balance is Fe. In this embodiment, the mass percent content of Ti and Nb satisfies Ti / Nb≥0.7, and Ti+Nb≥2.

[0026] The preparation method of the present embodiment heat-resistant steel comprises the following steps:

[0027] 1) Raw material preparation: The ingredients include by mass percentage: C: 0.7%, Cr: 25%, Ni: 45%, Mn: 1.0%, Si: 2.5%, Nb: 1.0%, W: 5.0%, Ti: 1.0% , the balance is Fe, and the alloy is prepared according to the above mass percentage;

[0028] 2) Smelting step: All the elements except Si and Mn in the above components are melted into the alloy mother liquid by induction furnace. After the molten steel reaches 1500°C, silicon and manganese are added for deoxidation, and P and S impurities in the mother liquid are controlled. The mass percen...

Embodiment 2

[0030] The precipitation-strengthened high-carbon austenitic heat-resistant steel in this embodiment includes, by mass percentage: C: 0.75%, Cr: 28%, Ni: 48%, Mn: 1.5%, Si: 2.1%, Nb: 0.5 %, W: 7.5%, Ti: 1.6%, and the balance is Fe.

[0031] The preparation method of the present embodiment heat-resistant steel comprises the following steps:

[0032] 1) Raw material preparation: The ingredients include by mass percentage: C: 0.75%, Cr: 28%, Ni: 48%, Mn: 1.5%, Si: 2.1%, Nb: 0.5%, W: 7.5%, Ti: 1.6% , the balance being Fe. , prepare the alloy according to the above mass percentage;

[0033] 2) Smelting step: All the elements except Si and Mn in the above components are melted into the alloy mother liquid by induction furnace. After the molten steel reaches 1500°C, silicon and manganese are added for deoxidation, and P and S impurities in the mother liquid are controlled. The mass percent content of the elements is all less than 0.03%, and then the molten steel is poured after the ...

Embodiment 3

[0035] The precipitation-strengthened high-carbon austenitic heat-resistant steel in this embodiment includes: C: 0.75%, Cr: 27%, Ni: 49%, Mn: 1.2%, Si: 2.4%, Nb: 1.2%, W: 7.0%, Ti: 0.9%, and the balance is Fe.

[0036] The preparation method of the present embodiment heat-resistant steel comprises the following steps:

[0037] 1) Raw material preparation: The ingredients include by mass percentage: C: 0.75%, Cr: 27%, Ni: 49%, Mn: 1.2%, Si: 2.4%, Nb: 1.2%, W: 7.0%, Ti: 0.9% , the balance is Fe, and the alloy is prepared according to the above mass percentage;

[0038] 2) Smelting step: All the elements in the above ingredients except Si and Mn are melted into the alloy mother liquor by using an induction furnace. After the alloy mother liquor reaches 1500°C, silicon and manganese are added for deoxidation, and P and S impurities in the mother liquor are controlled. The mass percent content of the elements is all less than 0.03%, and then the molten steel is poured after the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com