Patents

Literature

34results about How to "Refined Alloy Structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Leadfree SnZn-base alloy solder containing rare-earth elements

InactiveCN1390672AHigh bonding strengthImprove stabilityWelding/cutting media/materialsSoldering mediaRare-earth elementMetallic materials

A lead-free alloy as solder contains Zn (5-10 wt.%), the rare-earth elements chosen from La, Ce, Pr and Nd (0.05-1), one or more of Bi (0.1-6), Cu (0.1-3), In (0.5-3), Al (0.1-1), Ni (0.01-1) and P (0.001-1), and Sn (rest). Its advantages are better wettability, fine structure, excellent mechanical performance, low cost and no poison and pollution.

Owner:DALIAN UNIV OF TECH

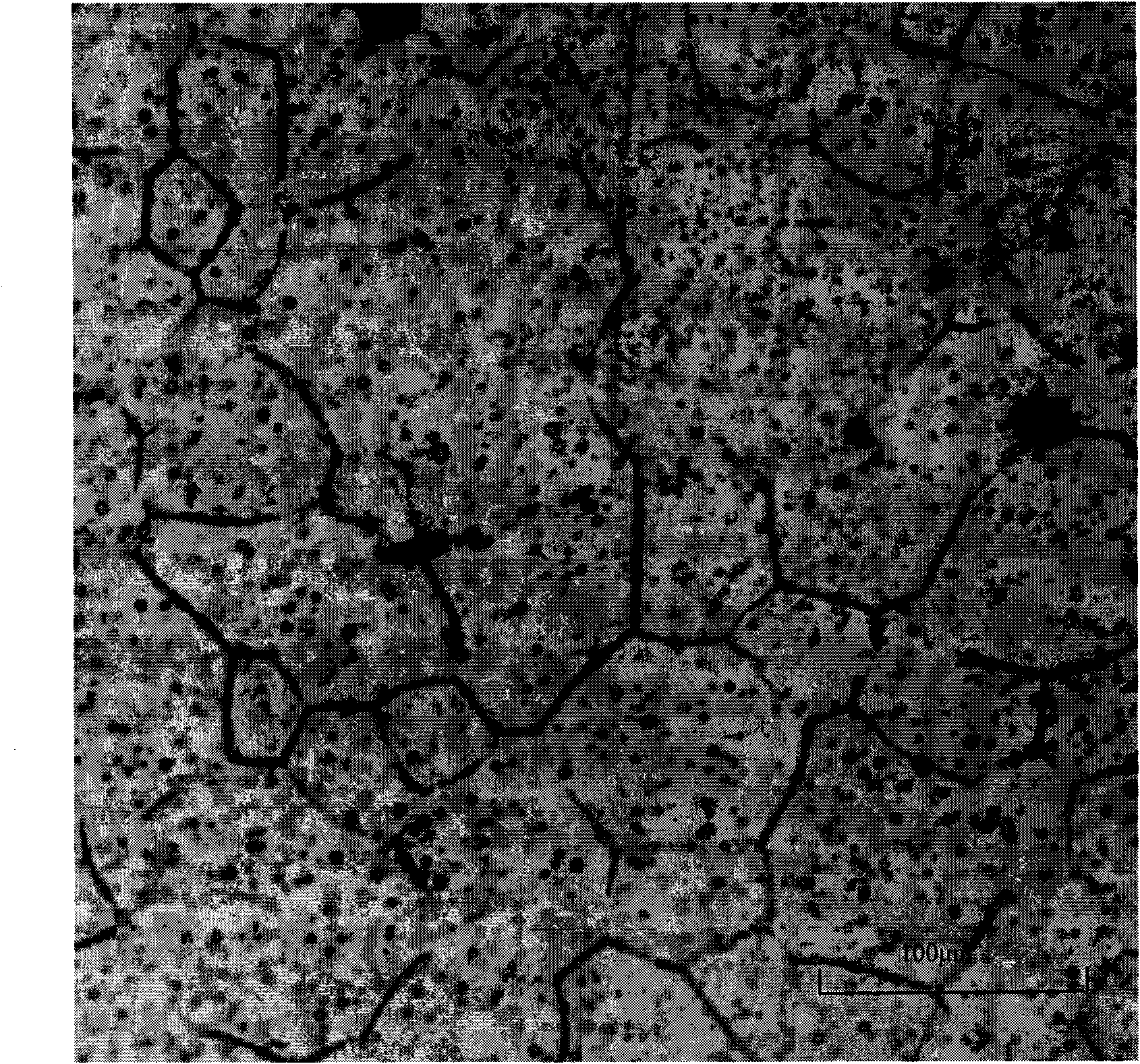

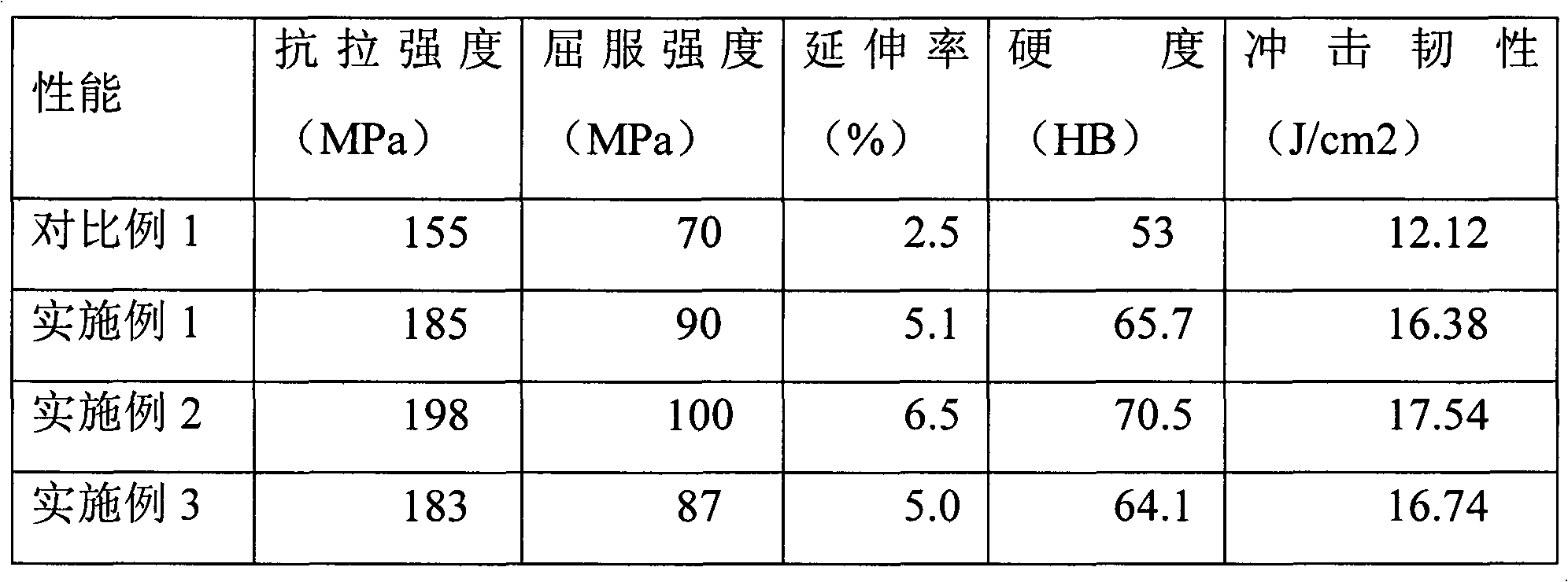

Wrought magnesium alloy and preparation method thereof

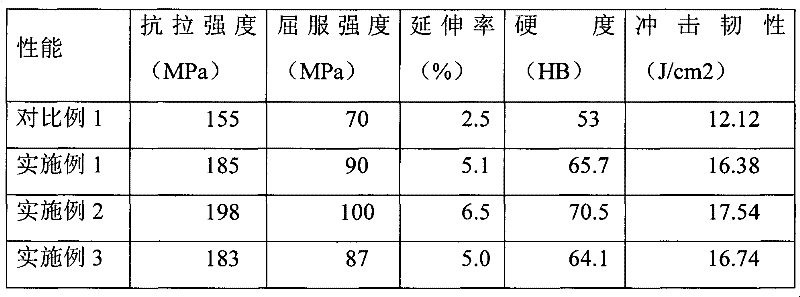

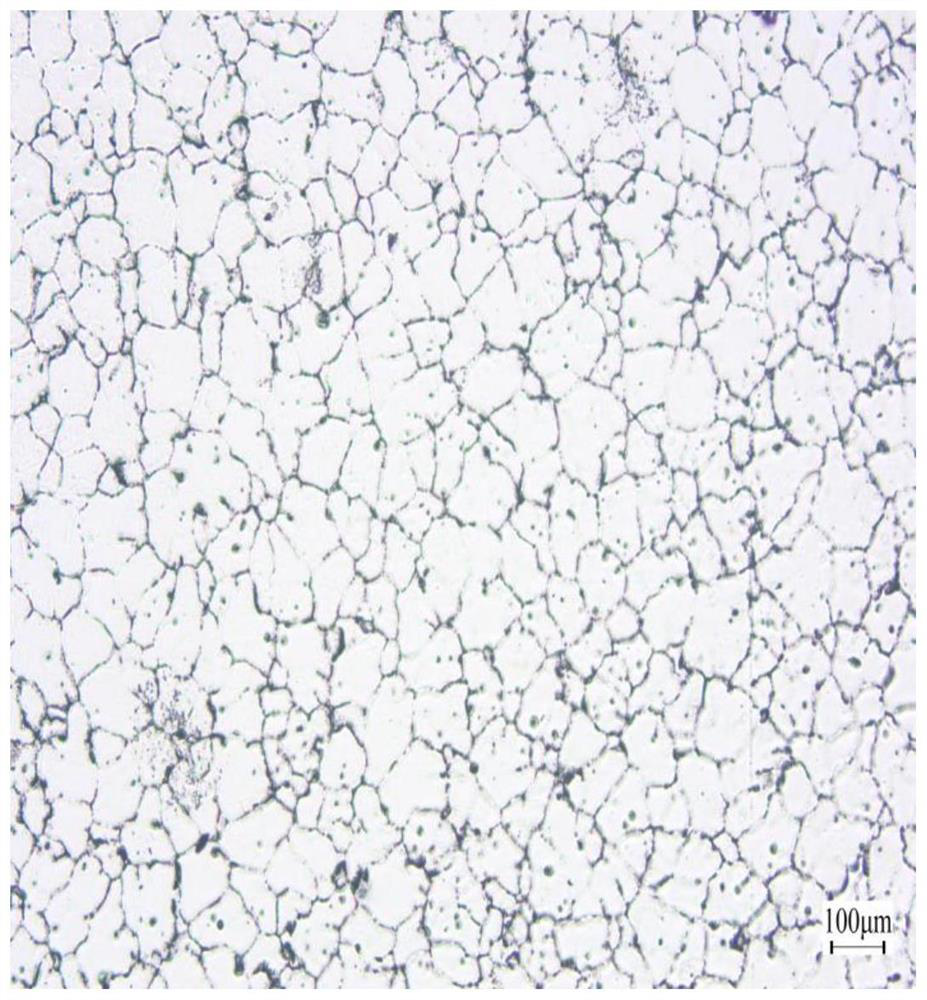

The invention relates to wrought magnesium alloy, which comprises the following ingredients in percentage by weight: 6.15 percent to 6.84 percent of Al, 1.05 percent to 1.36 percent of Zn, 0.20 percent to 0.45 percent of Mn, 0.50 percent to 1.50 percent of Sc and the balance Mg. The invention also relates to a preparation method of the wrought magnesium alloy. The wrought magnesium alloy and the preparation method have the advantages that the rare earth element Sc is adopted for modification treatment on the wrought magnesium alloy, the effects of refining crystal grains and improving the alloy tissue can be reached, through mechanical performance detection, the intensity, the plasticity, the hardness and the toughness of the wrought magnesium alloy are all improved through being comparedwith those of the magnesium alloy without the rare earth element Sc, and the later period processing formation is favorably realized.

Owner:BYD CO LTD

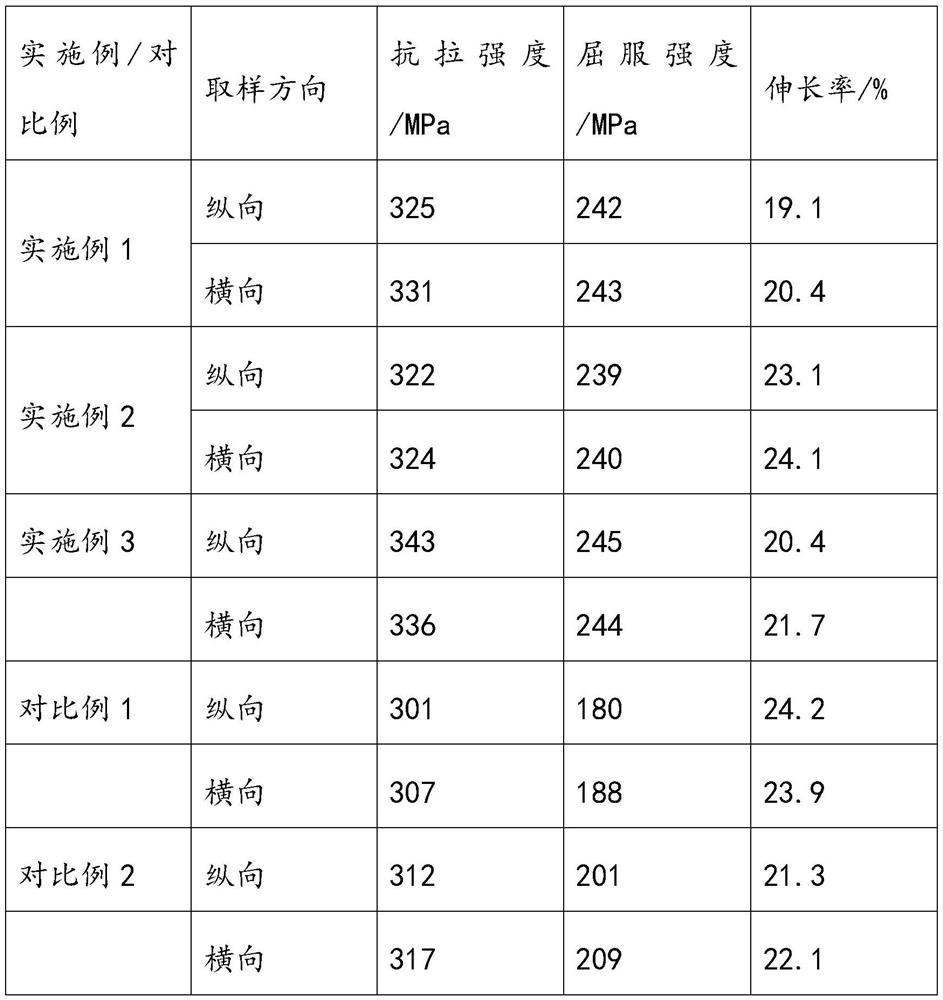

Manufacture process of automobile power battery enclosure

The invention provides a manufacture process of an automobile power battery enclosure, which comprises the following main steps of: (1) manufacturing aluminum alloy for the automobile power battery enclosure, wherein the aluminum alloy comprises the following components by weight percent: 0.10%<Si<0.60%, 0.40%<Fe<0.70%, 0.05%<Cu<0.20%, Mg<0.05%, 1.05%<Mn<1.25%, 0.15%<RE<0.40%, and 0.05<Ti<0.1, each of other elements is at most 0.05%, the total content of other elements is at most 0.15%, and the balance is aluminum; and (2) smelting the aluminum alloy proportioned by the step (1), casting the smelted aluminum alloy into a billet, and then sequentially carrying out four processes of homogenization, hot extrusion, heat treatment as well as punching and drawing on the billet to manufacture the automobile power battery enclosure. The automobile power battery enclosure manufactured through the process has excellent corrosion resistance, favorable high temperature creep property, and excellent punching-ironing processability and laser welding property, and is suitable for a square-shaped or box-shaped lithium ion battery case.

Owner:李其真

Novel copper-based dip brazing alloy for drilling bit

InactiveCN101890588AReasonable typeReasonable contentWelding/cutting media/materialsSoldering mediaChemical compositionBraze alloy

The invention discloses a novel copper-based dip brazing alloy used in drilling bit production. Cutting drill teeth and a drill body form a whole by dip brazing. The dip brazing copper alloy has excellent mechanical property and high strength, toughness and abrasion resistance. A brazing process is simple and convenient and suitable for brazing drill bits of multiple types. When the brazing temperature is between 900 and 1,000 DEG C, the alloy comprises the following chemical components in percentage by weight: 5 to 10 percent of Ni, 3 to 9 percent of Mn, 3 to 5 percent of Fe, 7 to 13 percent of Sn, 0.1 percent of sigma RE and the balance of Cu. When the brazing temperature is between 950 and 1,150 DEG C, the alloy comprises the following chemical components in percentage by weight: 8 to 15 percent of Ni, 10 to 13 percent of Mn, 5 to 10 percent of Zn, 1 to 2 percent of Fe, 0.05 to 0.1 percent of Ce and the balance of Cu. When the brazing temperature is between 1,100 and 1,250 DEG C, the alloy comprises the following chemical components in percentage by weight: 15 to 20 percent of Ni, 5 to 10 percent of Mn, 3 to 5 percent of Fe, 0.05 to 0.1 percent of sigma RE and the balance of Cu.

Owner:TIANJIN SANTIAOSHI NONFERROUS METAL FOUNDRY

Aluminum alloy for battery case of cell phones and preparing method thereof

ActiveCN102634698AAvoid poisoningGood refinement effectTelephone set constructionsMetallurgyAluminium alloy

The invention discloses aluminum alloy for battery cases of cell phones and preparing method of the aluminum alloy. The aluminum alloy contains the following ingredients in percentage by weight: 1.0-1.5% of Mn, 0.7% of Fe, 0.6% of Si, 0.05-0.20% of Cu, 0.1% of Zn, 0.06-0.03% of Ti, 0.0004-0.002% of C, 0.002-0.01% of RE, and the balance of Al. The aluminum alloy for the battery cases of the cell phones has extension resistance being up to 134.5Mpa at most and elongation being up to 28.7% at most, and is excellent in tenacity and strong in stamping resistance.

Owner:河南誉金技术服务有限公司

High-performance aluminum alloy and preparation method thereof

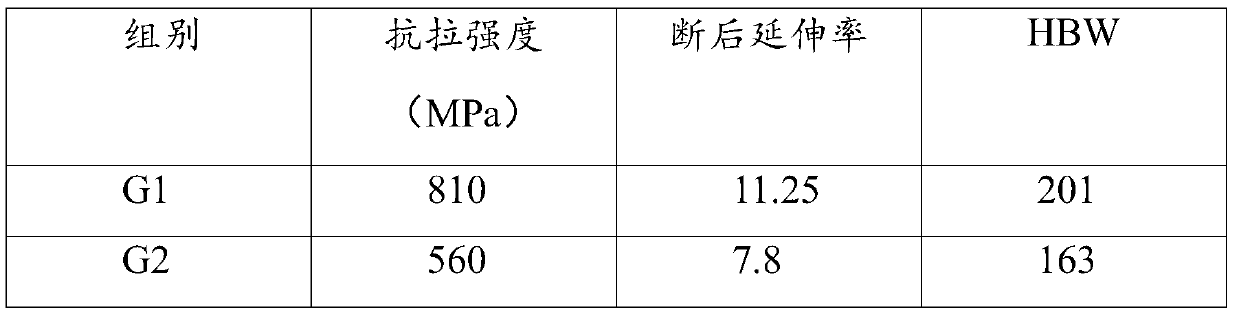

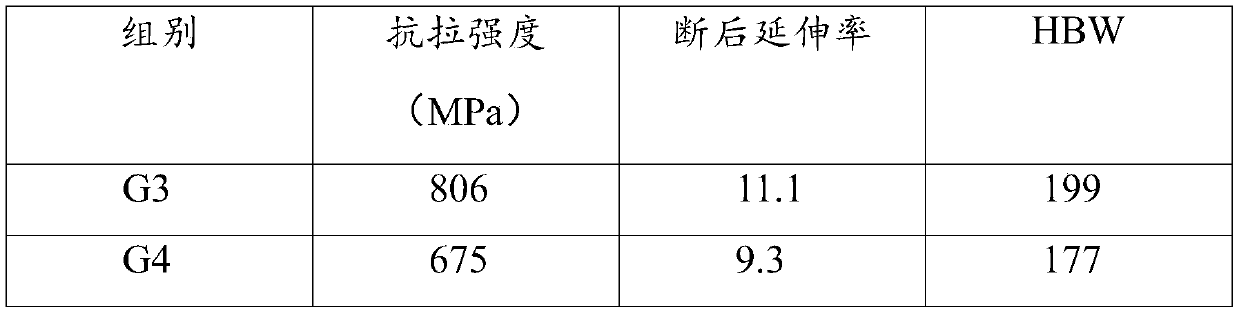

ActiveCN109811212AGrain refinementSuppression of dislocation movementFurnace typesHeat treatment furnacesAlloy elementHot stamping

The invention provides a high-performance aluminum alloy and a preparation method thereof. The high-performance aluminum alloy comprises the following components in percentage by weight: 11.2%-13.6% of Zn, 1.2%-1.8% of Mg, 0.2%-2.6% of Cu, 0.08%-0.25% of Zr, 0.04%-0.36% of Cr, 0.05%-0.3% of Mn, 0.02%-0.06% of Ti, 0%-0.15% of Fe, 0%-0.10% of Si, 0.05%-0.2% of W, 0.15%-2.0% of Ce and the balance Aland other inevitable impurity elements, wherein the percentage by mass of Zn and Mg is 6.5-11. According to the high-performance aluminum alloy, an efficient and rapid aluminum alloy integrating highstrength, high hardness, high-temperature resistance and corrosion resistance is especially provided for a hot-stamping forming technology by adding an appropriate amount of micro-alloy element W andrare-earth element Ce to an aluminum alloy matrix, increasing the mass ratio of Zn / Mg, and reducing the content of Cu; and the high-performance aluminum alloy has tensile strength of 720-816MPa, elongation after fracture of greater than 11%, and HBW value of 180-210.

Owner:WUHAN UNIV OF TECH

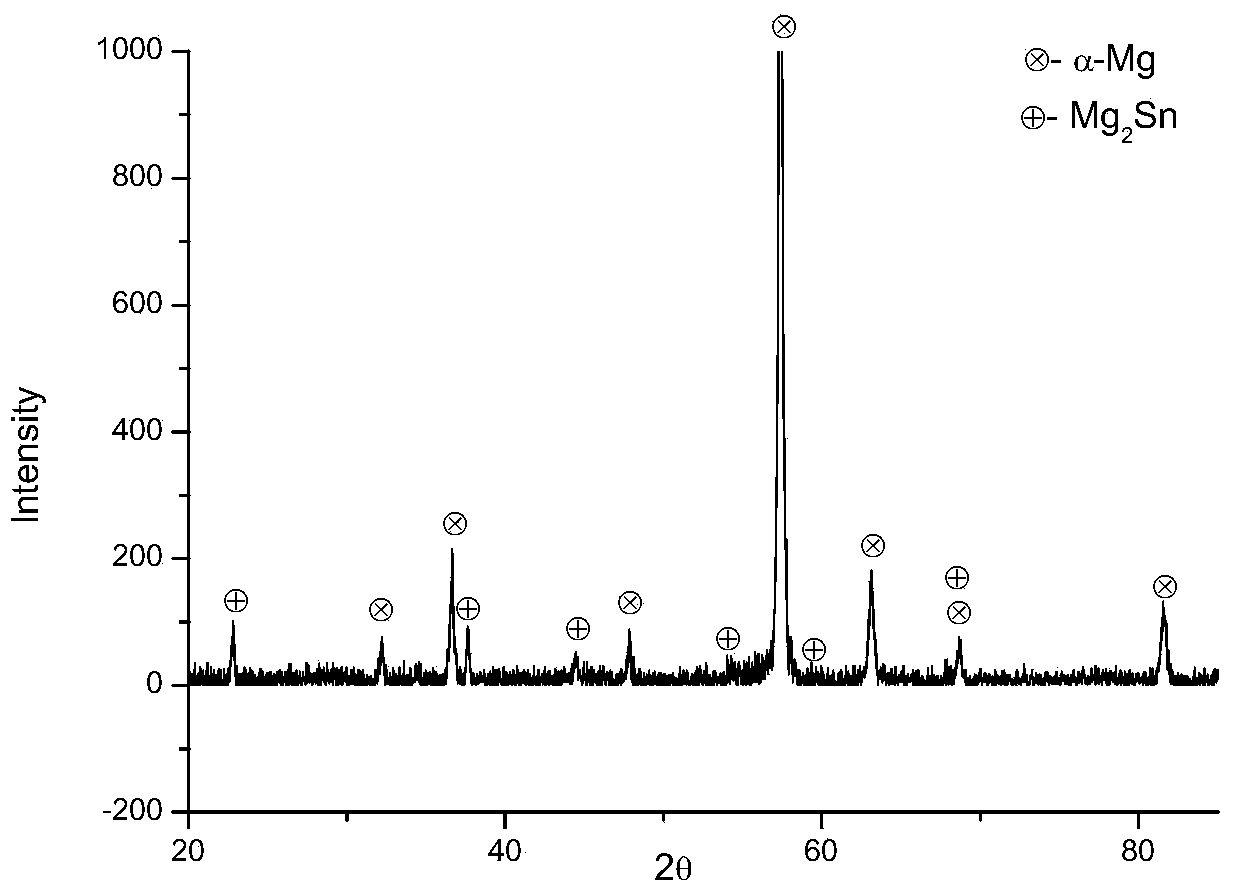

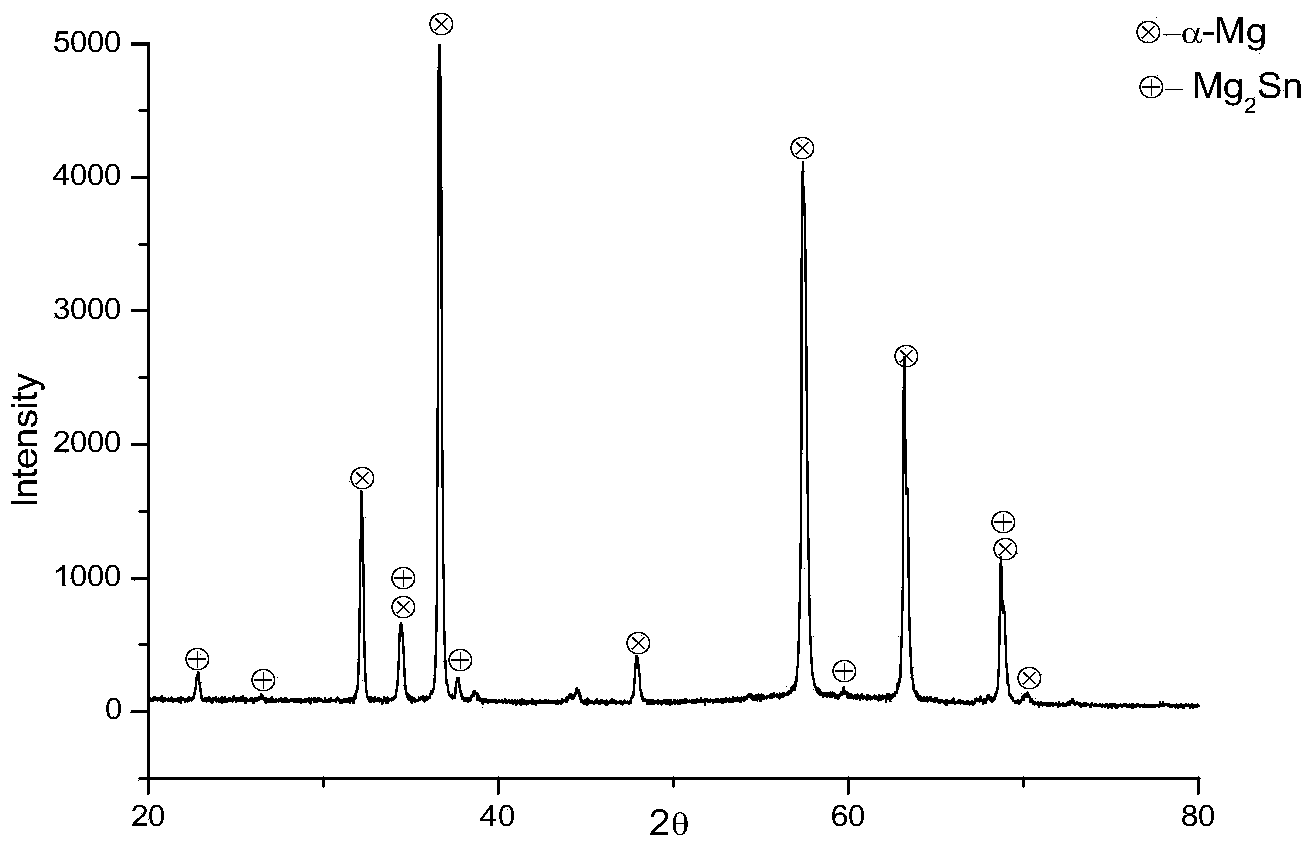

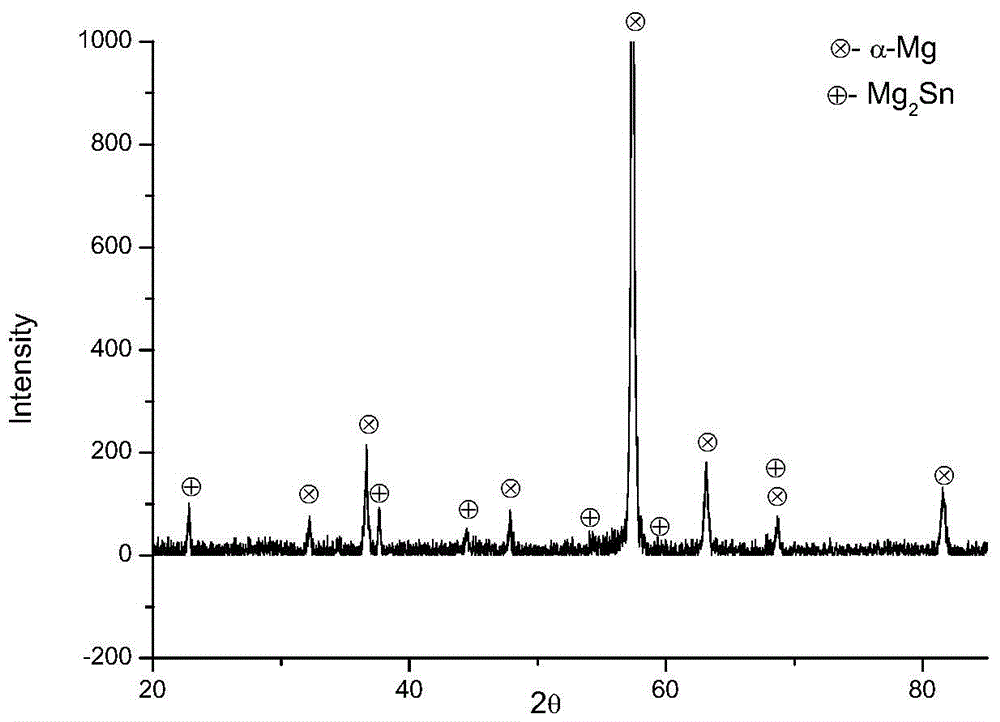

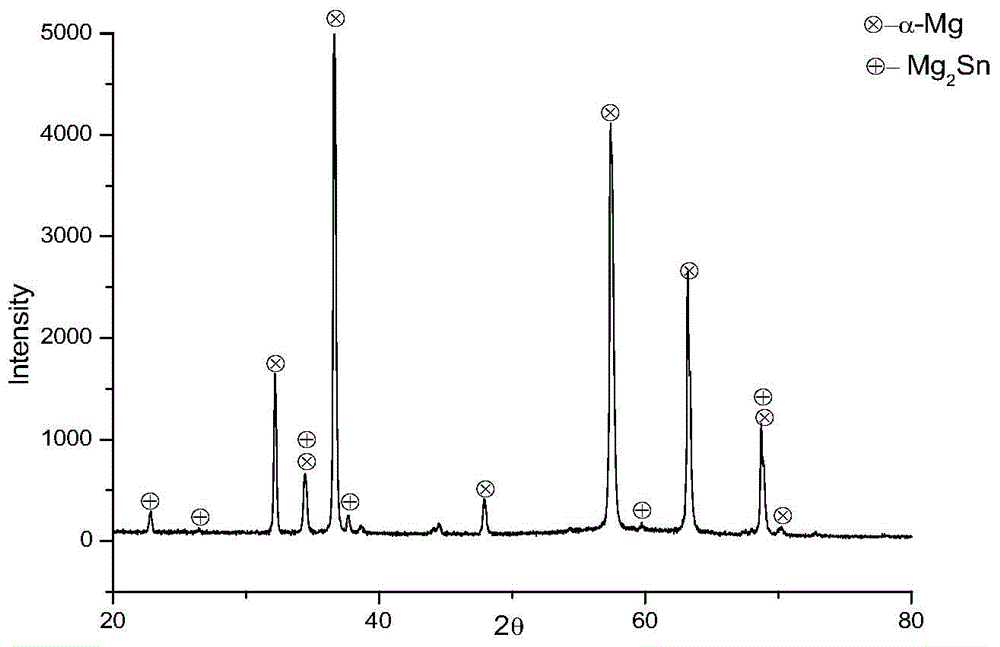

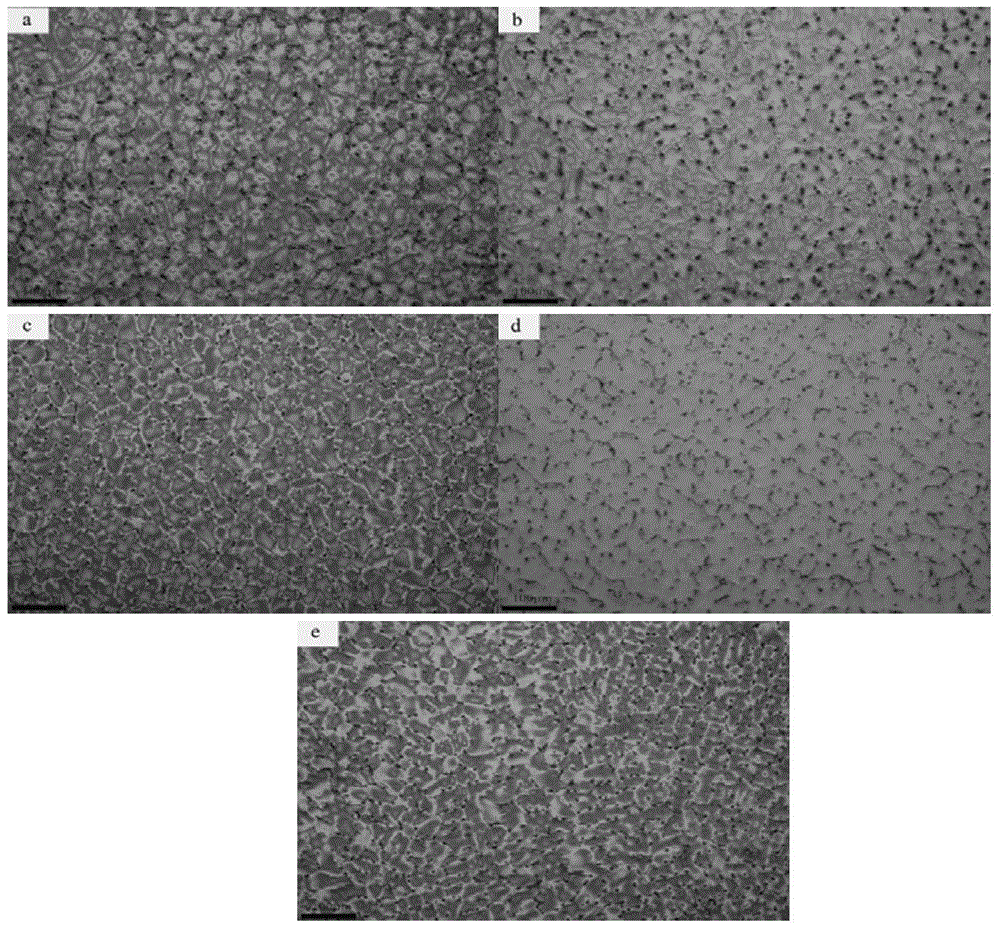

Magnesium-stannum-zinc-aluminum wrought magnesium alloy suitable for being extruded

The invention relates to a magnesium-stannum-zinc-aluminum wrought magnesium alloy suitable for being extruded. The wrought magnesium alloy comprises the following components in percentage by mass: 3-5% of Sn, 1% of Al, 0.5-2.0% of Zn, less than or equal to 0.10% of inevitable impurities and the balance of Mg. According to the alloy provided by the invention, the Mg-Sn magnesium alloy is subjected to modification treatment by adopting Zn and Al, so that the grains can be refined and the alloy tissue can be improved. Meanwhile, the tensile strength and the ductility of the alloy are improved to facilitate processing and moulding in the later period. The wrought magnesium alloy provided by the invention is simple in preparation method, relatively low in equipment cost and easy to implement.

Owner:CHONGQING UNIV

Magnesium alloy thick plate and preparation method thereof

ActiveCN112481536ASolve rolling difficultiesSolve the mechanical propertiesThick plateMagnesium alloy

The invention aims to provide a preparation method of a novel magnesium alloy thick plate. The alloy comprises, by mass, 3.5-5.0% of Al, 2.0-3.5% of Zn, 0.1-0.8% of Mn, 0.01-0.80% of RE, 0.001-0.090%of Ca, less than or equal to 0.005% of Fe, less than or equal to 0.05% of Si, less than or equal to 0.005% of Cu, less than or equal to 0.005% of Ni and the balance Mg, and the total content of impurities does not exceed 0.1%, wherein the sum of the Al content and the Zn content satisfies the condition that Al+Zn is greater than or equal to 6% and less than or equal to 8%. Aiming at a novel Mg-Al-Zn alloy system, a forming process for preparing the large-size magnesium alloy thick plate with low anisotropy and high strength is developed to satisfy urgent demands of such fields as aerospace, weaponry and automobiles on the magnesium alloy thick plate with low cost and high performance.

Owner:CHANGSHA ADVANCED MATERIALS IND RES INST CO LTD

Copper-containing ferro-aluminum alloy wire and fabrication method thereof

The invention relates to a copper-containing ferro-aluminum alloy wire and a fabrication method thereof. The copper-containing ferro-aluminum alloy wire is composed of the following components of 0.03%-0.08% of silicon, 0.3%-0.8% of iron, 0.15%-1.5% of copper, 0.001%-0.1% of zinc, 0.01%-0.05% of boron, 0.01%-0.04% of mixed elements, 0.001%-0.03% of magnesium, 97.4%-99.5% of aluminum and other impurities, the total content of other impurities is at most 0.10%, and the content of single impurity is at most 0.03%. The mixed elements include manganese, vanadium, chromium and titanium. The fabrication method includes the following steps of (1) a burdening process, (2) an oven baking process, (3) a melting process, (4) a refining process, (5) a casting process, (6) a continuous rolling process, (7) a wire drawing process and (8) an annealing process. Small burning loss and mechanical properties in the ferro-aluminum alloy wire production process are guaranteed. The fabrication method is simple and fast, the product cost is moderate, the product quality is stable, and the type of products can be continuously and stably provided.

Owner:安徽华纳合金材料科技有限公司

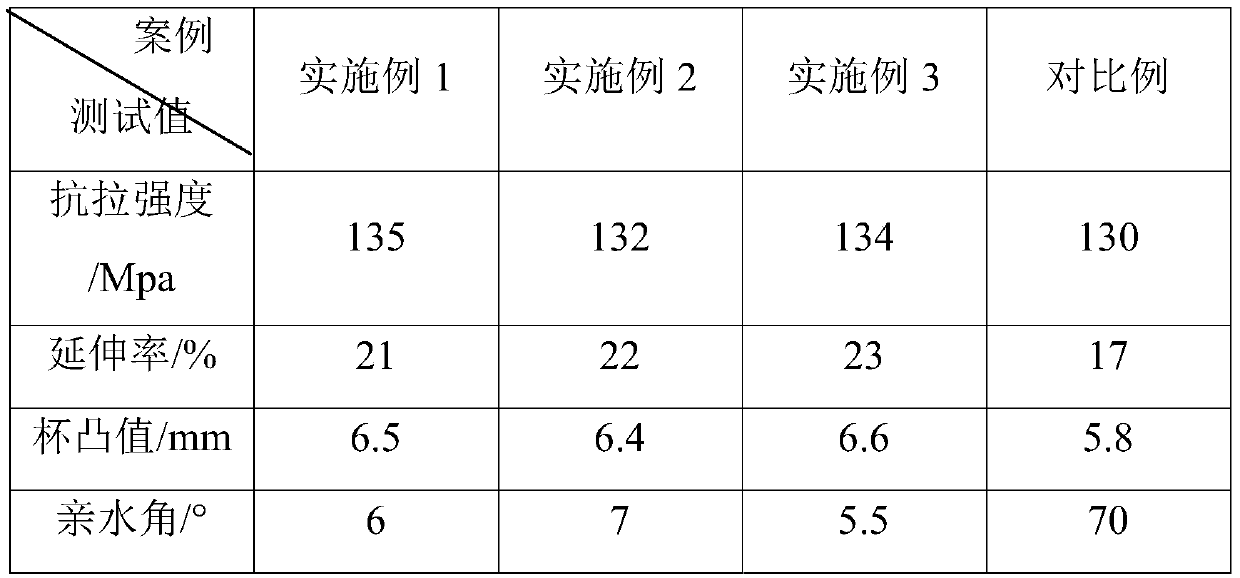

Air conditioner foil and preparation method thereof

InactiveCN110592434AImprove the lubrication effectImprove hydrophilicityFurnace typesHeat treatment furnacesPunch pressUltimate tensile strength

The invention discloses an air conditioner foil. The air conditioner foil comprises the following components of, in percentage by mass, 0.2% to 0.3% of Si, 1.4% to 1.5 % of Fe, less than or equal to 0.05% of Cu, 0.5% to 0.6 % of Mn, less than or equal to 0.05 % of Zn, less than or equal to 0.03 % of Ti, and the balance Al. The invention also discloses a preparation method of the air conditioner foil. The preparation method of the air conditioner foil comprises the following steps that, raw materials are subjected to smelting and cast rolling according to the components and the mass percentage;the cast-rolled blank is firstly subjected to homogenization annealing, then cold rolling is carried out, and finished product performance annealing is carried out after cold rolling; and a coatingcoats the surface of the finished product. According to the air conditioner foil and preparation method thereof, the machining performance is excellent, the strength is high, the plasticity is good and the flanging height is greatly increased, the problem of flanging cracking in the machining process of air conditioner foil fins is effectively avoided, the machining requirements of a high-speed punching machine are simultaneously met, and the machining efficiency is greatly improved.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

Low-lead brass alloy and preparing method thereof

A low-lead brass alloy is provided. The low-lead brass alloy comprises 0.4-0.7 wt% of aluminum, 0.42-1.20 wt% of bismuth, 0.05-1.0 wt% of iron, more than 96.5 wt% of copper and zinc, less than 0.2 wt% of lead, and unavoidable impurities, wherein the copper content in the brass alloy is 59-63 wt%. The invention also relates to a preparing method of the brass alloy. The brass alloy has characteristics of good alloy air tightness, degree of density and polishing performance, and overcomes the technical barrier that the content of the bismuth cannot be higher than 0.5 wt%. The alloy, which can replace lead-containing brass and has good corrosion resistance, casting performance, machinability, corrosion resistance and mechanical properties, and the preparing method thereof are truly provided.

Owner:泉州华毅商贸有限公司

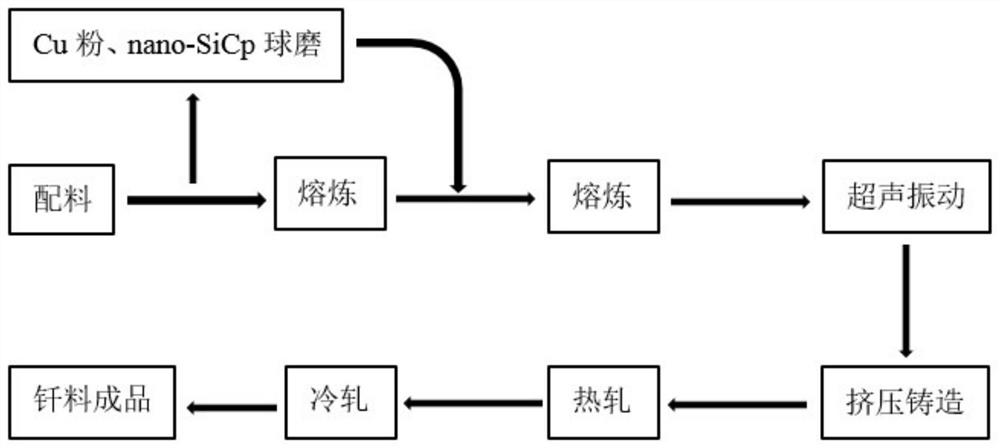

Compound brazing filler metal used for hard alloy tool brazing and preparation method thereof

ActiveCN111889917AEvenly dispersedGood dispersionWelding/cutting media/materialsSoldering mediaCrucibleIngot

The invention relates to compound brazing filler metal used for hard alloy tool brazing. The compound brazing filler metal is composed of 25%-27% of Ag, 37%-39% of Cu, 3.0%-5.0% of Mn, 2.0-4.0% of Ni,1.5%-2.5% of In, 0.5%-1.0% of nano-SiCp, 0.15%-0.3% of Si, 0.1%-0.2% of B, 0.05%-0.1% of Co, 0.01%-0.05% of Fe, 0.01%-0.1% of La, Ce and Y mixed rare earth and the balance Zn, wherein the mixed rareearth includes at least two of La, Ce and Y. A preparation method includes the steps that firstly, raw materials are weighed according to the ratio; secondly, segmented variable-speed high-energy ballmilling is conducted on Cu powder and nano-SiCp to obtain Cu / nano-SiCp particles; thirdly, the Ag, Cu ingots, the Zn, the Mn, the Ni, the Si, the Co and the Fe are placed in a medium-frequency induction smelting furnace to be heated and molten, and then the In, the B, the Cu foil wrapped mixed raw earth and the Cu / nano-SiCp particles are sequentially added in a crucible; fourthly, the mixture ismoved into a well type resistance furnace to be subjected to ultrasonic vibration and squeeze casting forming; and fifthly, hot rolling and cold rolling are conducted on cast ingots to form the foil sheet brazing filler metal. By means of segmented variable-speed ball milling and ultrasonic vibration, uniform dispersion of the nano-SiCp is ensured, the brazing filler metal is good in wettability and joint filling capacity, the brazing manufacturability is good, the preparation method is simple, and the finished product rate is high.

Owner:YUNNAN PRECIOUS METALS LAB CO LTD

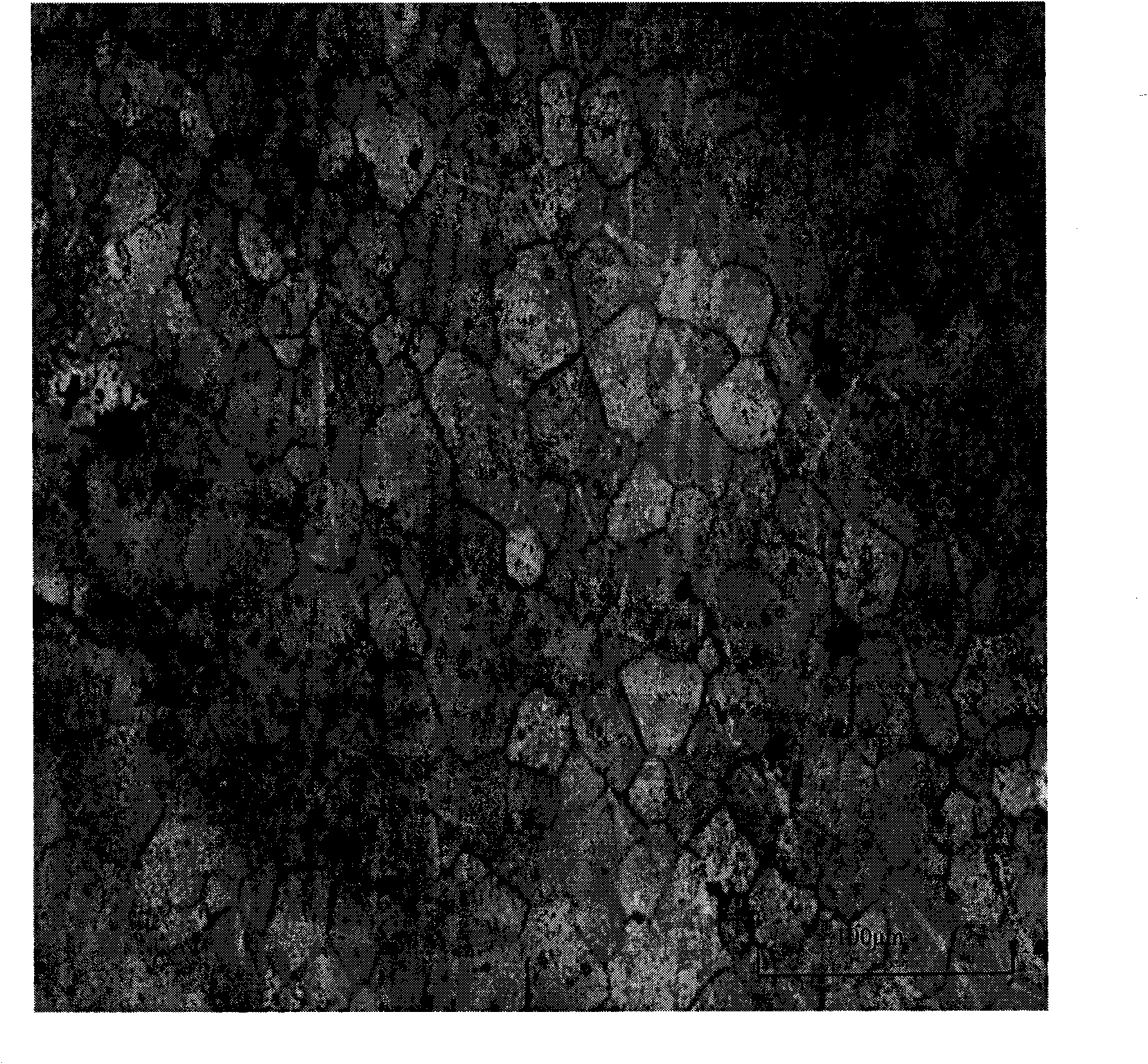

Rare earth aluminum alloy bar for forging aluminum alloy hub and preparation method of rare earth aluminum alloy bar

InactiveCN114231802AHigh strengthImprove plasticityLanthanoid Series ElementsUltimate tensile strength

The invention discloses a rare earth aluminum alloy bar for forging an aluminum alloy hub. The rare earth aluminum alloy bar comprises, by mass, 0.6%-0.8% of Si, 0.15%-0.25% of Fe, 0.2%-0.3% of Cu, 0.06%-0.10% of Mn, 0.8%-1.2% of Mg, 0.2%-0.3% of Cr, smaller than or equal to 0.05% of Zn, 0.02%-0.06% of Ti, 0.05%-0.20% of LaCe mixed rare earth and the balance Al. The invention further discloses a preparation method of the rare earth aluminum alloy bar for forging the aluminum alloy hub. The lanthanum and cerium rare earth elements mixed in a certain proportion are added into the aluminum alloy, so that the alloy structure of the rare earth aluminum alloy bar is improved, and the strength and plasticity are improved.

Owner:BAOTOU RES INST OF RARE EARTHS

Leadfree SnZn-base alloy solder containing rare-earth elements

InactiveCN1175956CImprove organizationImprove mechanical propertiesWelding/cutting media/materialsSoldering mediaRare-earth elementMetallic materials

A lead-free alloy as solder contains Zn (5-10 wt.%), the rare-earth elements chosen from La, Ce, Pr and Nd (0.05-1), one or more of Bi (0.1-6), Cu (0.1-3), In (0.5-3), Al (0.1-1), Ni (0.01-1) and P (0.001-1), and Sn (rest). Its advantages are better wettability, fine structure, excellent mechanical performance, low cost and no poison and pollution.

Owner:DALIAN UNIV OF TECH

Pouring and polishing process for propeller and copper alloy formula for propeller

ActiveCN105690040AImprove corrosion resistance and impact resistanceRefined Alloy StructureMelt-holding vesselsPropellersPropellerSeawater

The invention discloses a pouring and polishing process for a propeller and a copper alloy formula for the propeller. A copper-aluminum alloy consists of the following components in percentage by weight: 7-10% of aluminum, 8-20% of manganese, 4-6% of iron, 1-3% of nickel, 1-6% of zinc, 0.1-0.3% of titanium, 0.1-0.3% of chromium, 0.010-0.025% of cobalt and the balance of copper. On the basis of the copper alloy, microelements of titanium, chromium and cobalt are added, so that the toughness, cavitation erosion resistance and seawater corrosion resistance of the propeller are integrally improved, and the service life of the propeller is prolonged. A propeller workpiece is polished into a finished product through the working procedures of primary milling, detecting, polishing, blade surface coarse grinding, milling, edging and finishing; the finished product is high in smoothness and good in levelling effect; a stress structure cannot be damaged; water resistance during use is small; and the service life is long.

Owner:TAIZHOU JIAOJIANG YONGGU SHIP PROPELLER FACTORY

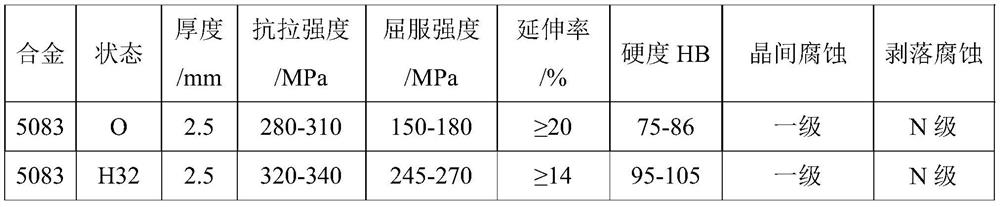

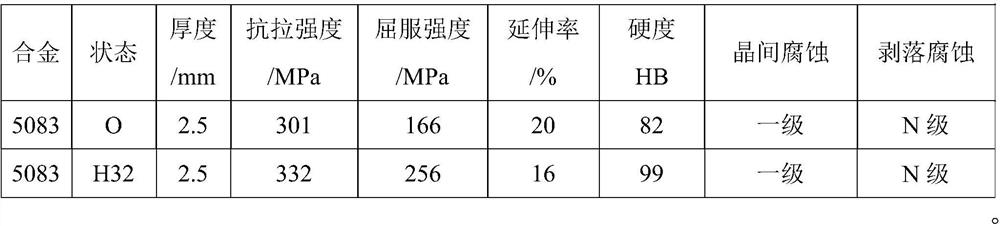

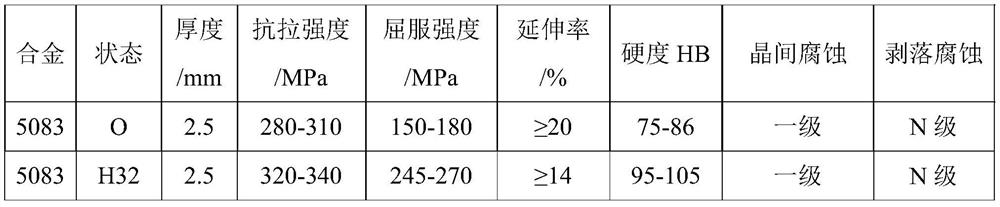

High-strength aluminum plate for truck fuel tank and production method therefor

ActiveCN113862498AImprove corrosion resistanceInhibition of recrystallizationFurnace typesHeat treatment furnacesFuel tankIngot

The invention discloses a high-strength aluminum plate for a truck fuel tank and a production method therefor. Pure aluminum ingots, pure magnesium ingots and pure zinc ingots are used as raw materials to be smelted, intermediate alloy ingredients are added to be smelted, and the components of obtained alloy liquid meet the alloy element composition of the aluminum plate; the obtained alloy liquid is sequentially subjected to refining, casting, surface milling, soaking treatment, hot rough rolling and hot finish rolling, and an aluminum alloy blank coil is prepared; cold rolling is performed on the obtained coil to obtain cold-rolled coil materials with two thicknesses of 2.5 mm and 3.5 mm; sequential annealing and cleaning are performed on the obtained coil material with the thickness of 2.5 mm to obtain an O-state finished coil material; and the obtained cold-rolled coil material with the thickness of 3.5 mm is sequentially subjected to intermediate annealing, secondary cold rolling, stabilizing treatment and cleaning, and an H32-state finished product coil is obtained. The product prepared by the invention has excellent mechanical properties, corrosion resistance and punch forming performance, and can effectively solve the technical problem of punch cracking of the fuel tank caused by poor corrosion resistance and low elongation of the fuel tank of the truck.

Owner:河南泰鸿新材料有限公司

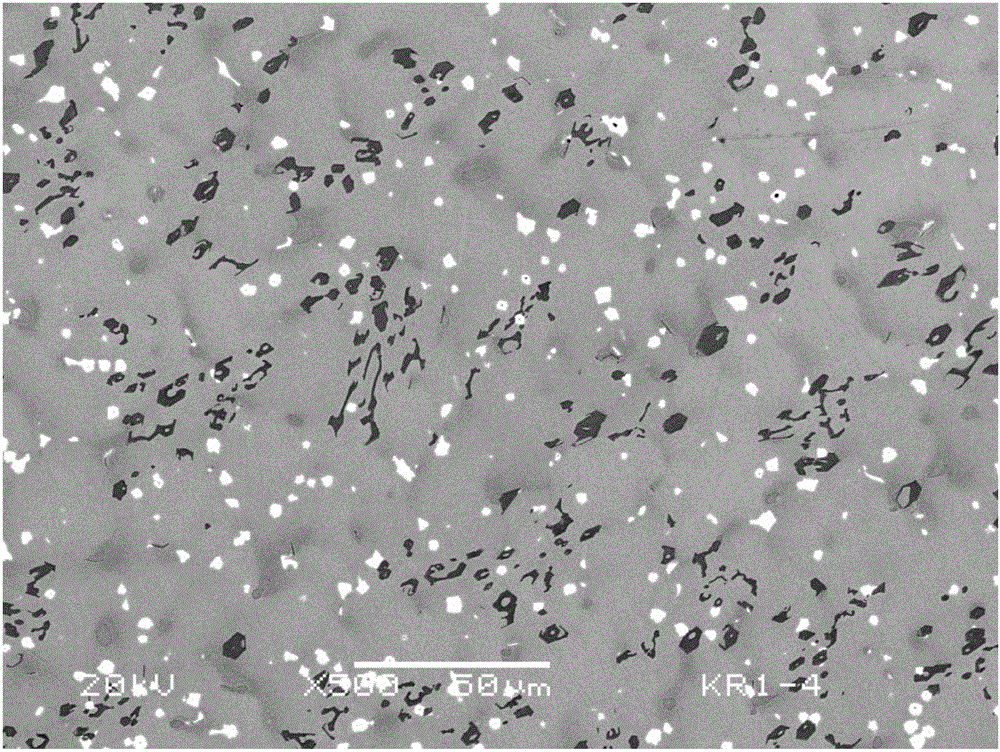

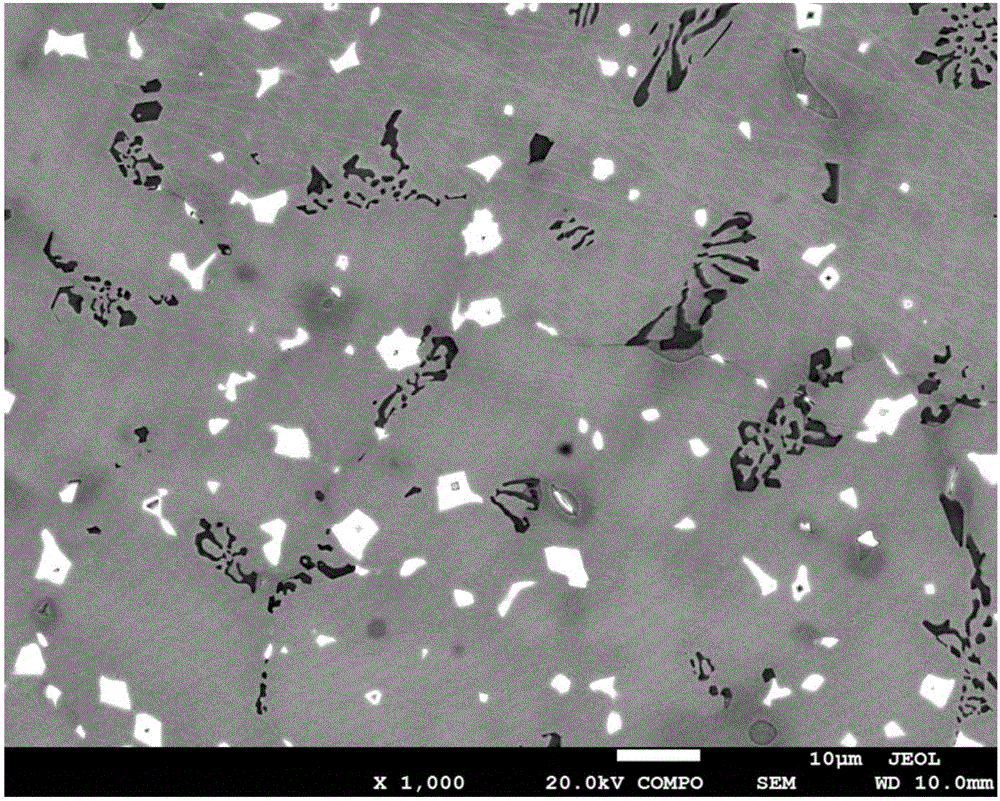

Boron-containing wear-resistant alloy steel and preparation method thereof

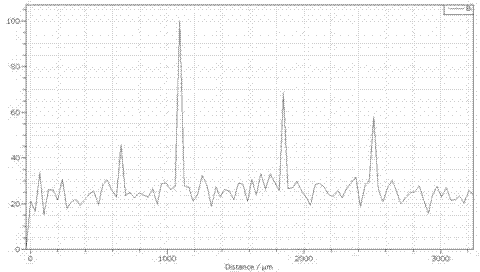

The invention relates to boron-containing wear-resistant alloy steel and a preparation method thereof. The alloy steel is prepared from the following components in percentage by weight: 0.6-0.9% of C,5-5.8% of Cr, 0.5-1.4% of B, 0.5-0.8% of Ni, 0.6-1.0% of Mn, 0.6-1.0% of Si, 0.35-0.5% of Nb, 1.0-2.0% of W, 0.55-0.75% of Ti, less than 0.03% of S, less than 0.03% of P and the balance of Fe and inevitable impurity elements. The boron-containing wear-resistant alloy steel is prepared by adopting a compound method of modification and mechanical vibration. The preparation method comprises the following steps: adding Ti, Nb and W into molten steel for modification; pouring smelted molten iron into a cast fixed to a vibrating device; and starting the vibrating device after pouring to vibrate themolten steel mechanically. According to the invention, grains can be refined effectively, shapes and distribution of borides in tissues can be improved, and the impact toughness of the material can be improved while the hardness of the material is guaranteed. Moreover, required equipment and process are simple, the adding amount of noble metals is small, the production cost is low, and the boron-containing wear-resistant alloy steel is easily popularized and applied in industrial production.

Owner:GUANGDONG INST OF MATERIALS & PROCESSING

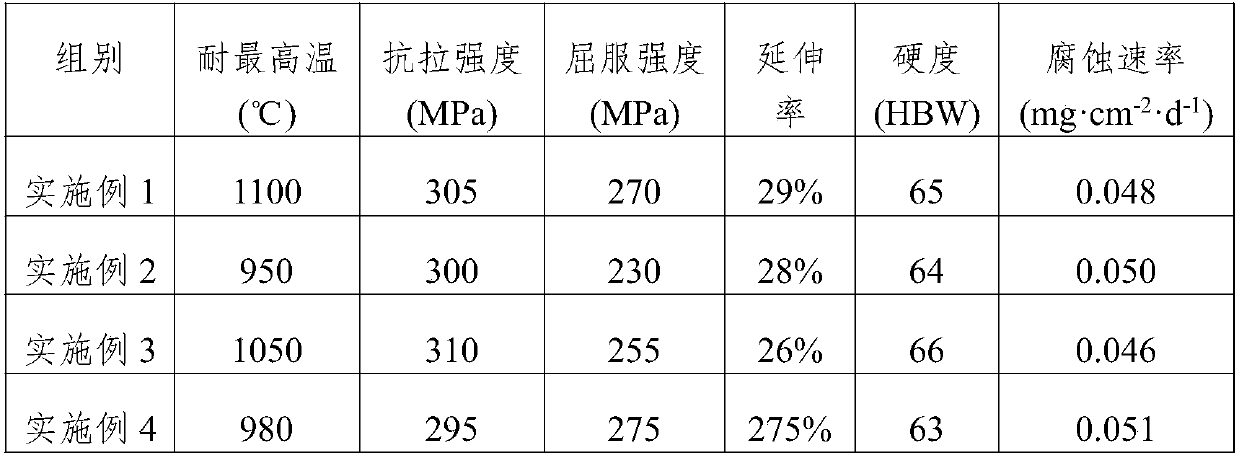

High-temperature-resistant and corrosion-resistant magnesium alloy and preparation process thereof

InactiveCN109628811AHigh temperature resistantHigh tensile strengthRare-earth elementTemperature resistance

The invention discloses a high-temperature-resistant and corrosion-resistant magnesium alloy. The magnesium alloy is mainly prepared from the following components in percentage by mass: 4.5-6.9% of Mo, 6.6-8.8% of Zn, 2.3-3.2% of Zr, 0.1-0.6% of Sc, 0.1-0.5% of W, 1.2-1.8% of rare earth elements, and the balance of Mg and unavoidable impurities; and the unavoidable impurities are Ca, Al and the like, and the total amount of the unavoidable impurities is less than 0.05%. The prepared magnesium alloy has high-temperature resistance, corrosion resistance and good toughness, the tensile strength and the yield strength are also improved, the elongation is also increased, and the performance of the magnesium alloy is improved.

Owner:贵州航天风华精密设备有限公司

A Magnesium-Tin-Zinc-Al Deformed Magnesium Alloy Suitable for Extrusion

The invention relates to a magnesium-stannum-zinc-aluminum wrought magnesium alloy suitable for being extruded. The wrought magnesium alloy comprises the following components in percentage by mass: 3-5% of Sn, 1% of Al, 0.5-2.0% of Zn, less than or equal to 0.10% of inevitable impurities and the balance of Mg. According to the alloy provided by the invention, the Mg-Sn magnesium alloy is subjected to modification treatment by adopting Zn and Al, so that the grains can be refined and the alloy tissue can be improved. Meanwhile, the tensile strength and the ductility of the alloy are improved to facilitate processing and moulding in the later period. The wrought magnesium alloy provided by the invention is simple in preparation method, relatively low in equipment cost and easy to implement.

Owner:CHONGQING UNIV

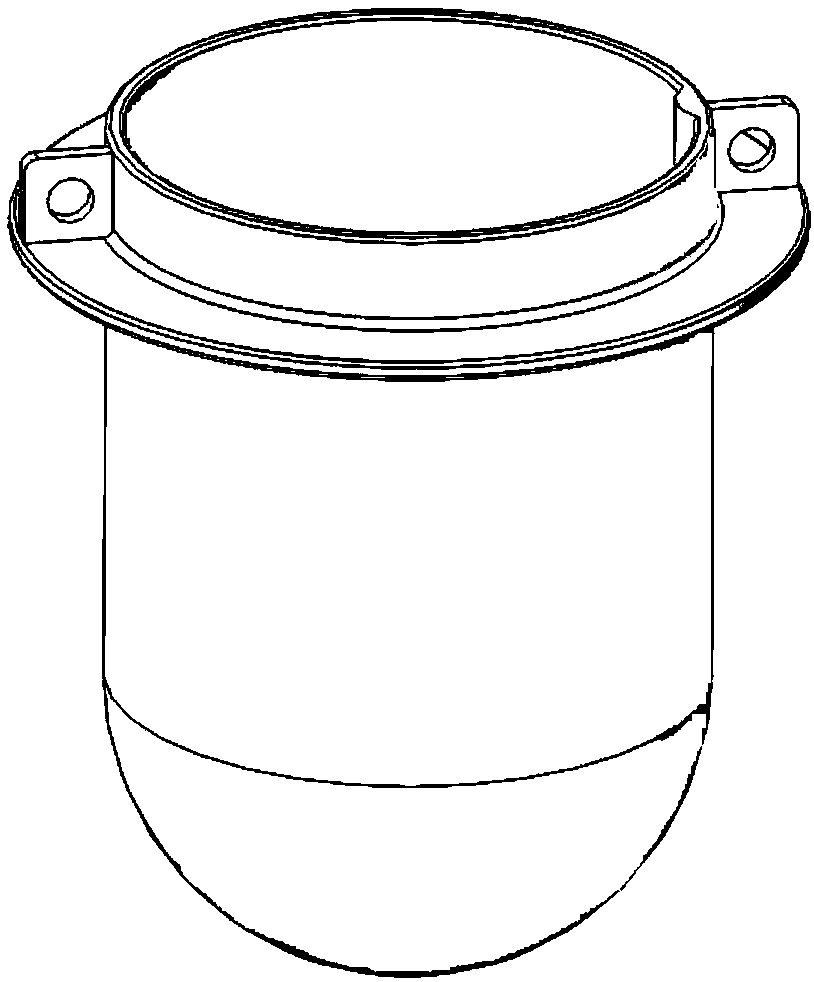

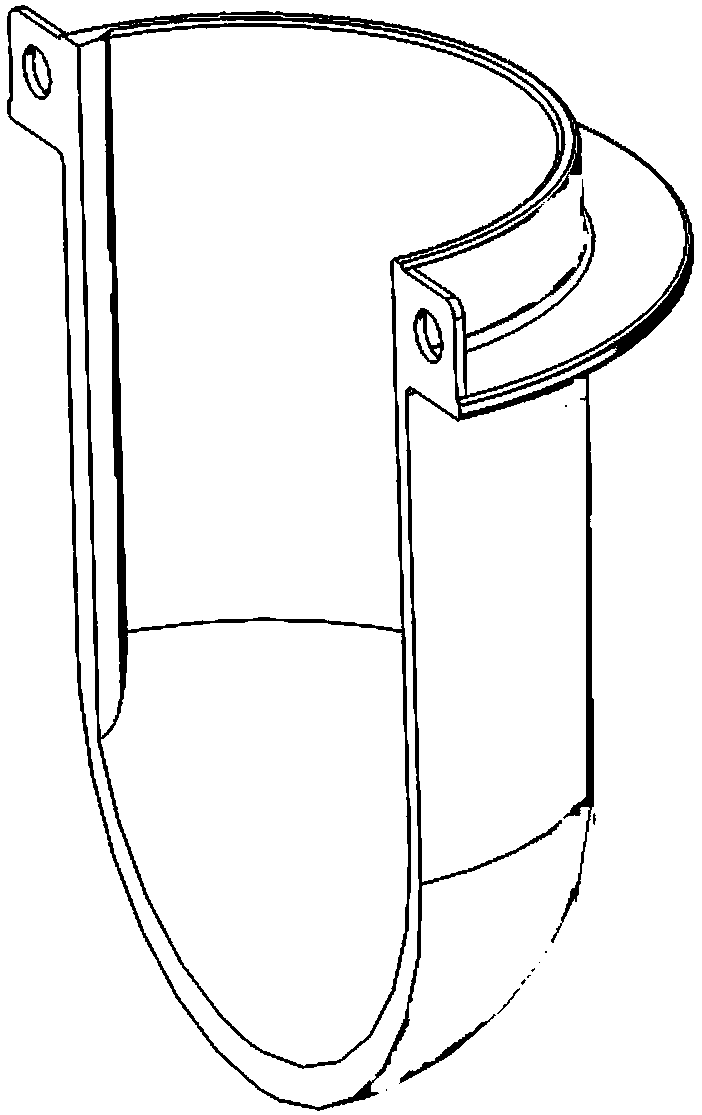

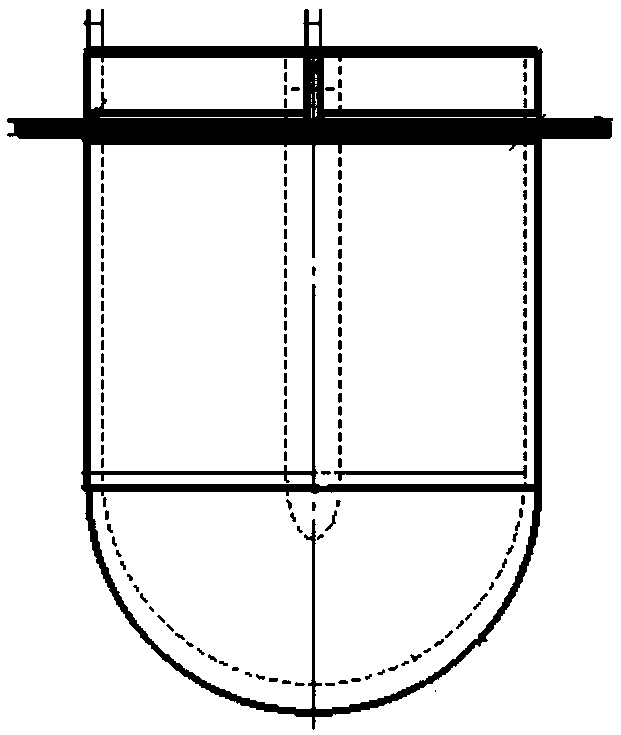

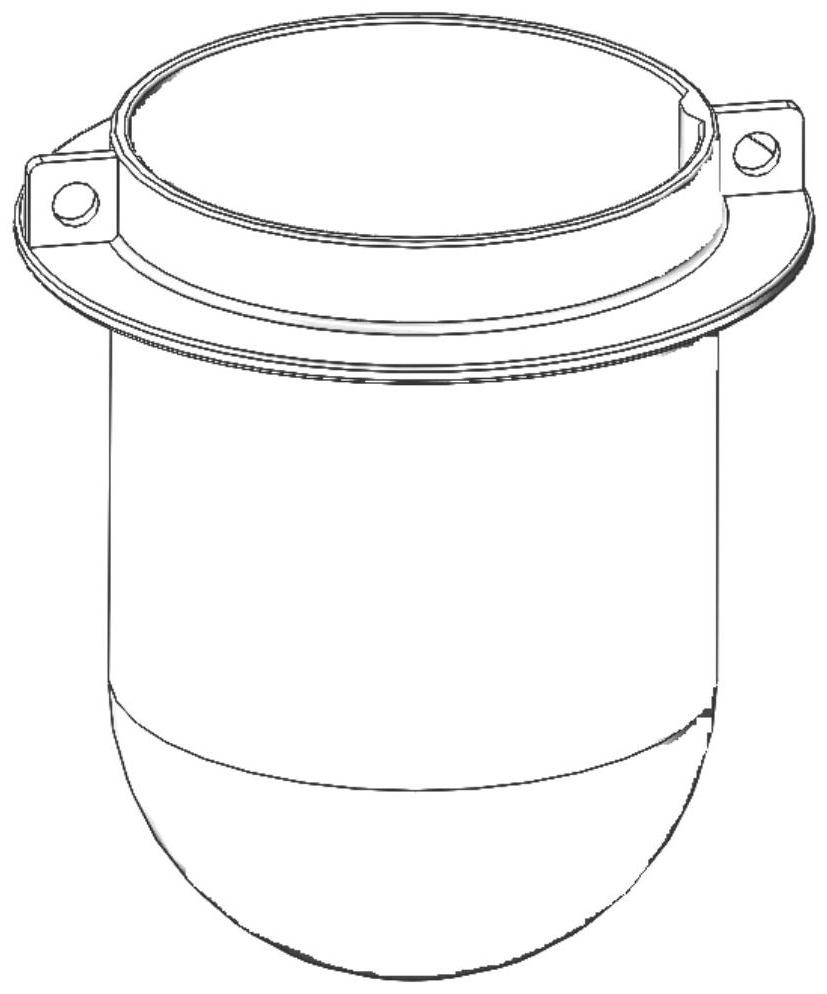

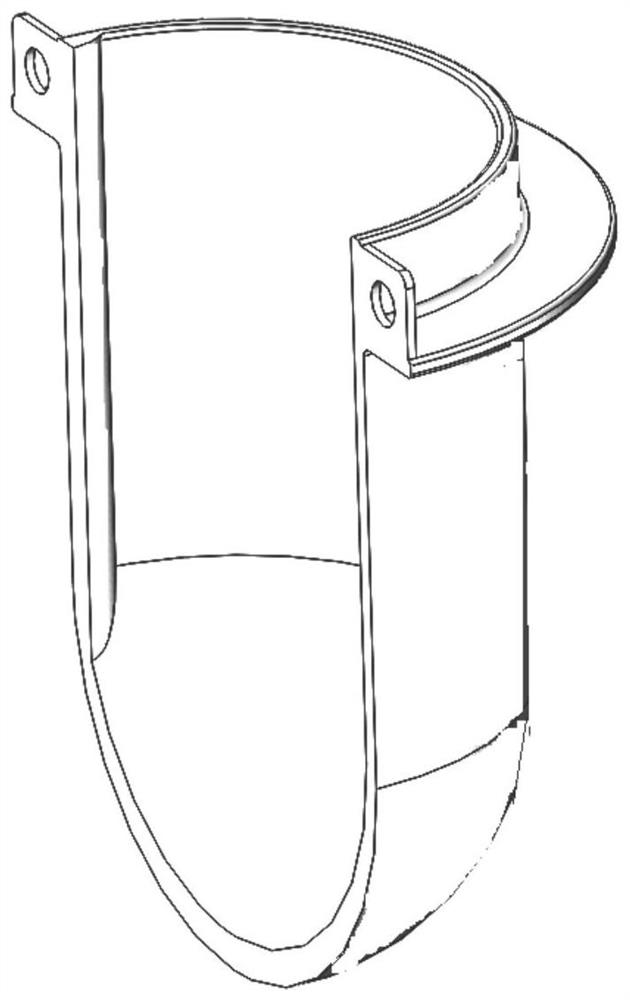

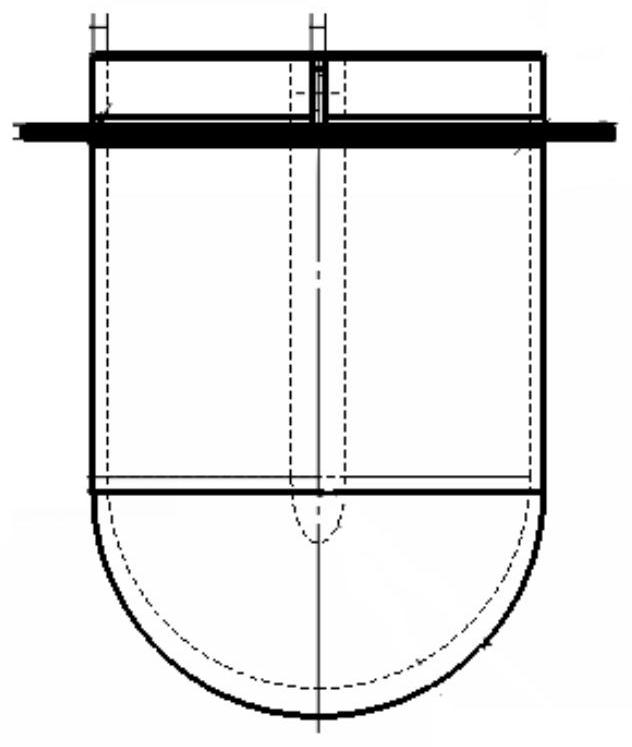

Heat-resistant anticorrosion metallic magnesium refining kettle and preparation method thereof

ActiveCN108950386AImprove heat resistanceImprove corrosion resistanceFurnace typesHeat treatment furnacesFerrosiliconMaterials science

The invention discloses a metallic magnesium refining kettle and a preparation method thereof. The metallic magnesium refining kettle is prepared through an evaporative pattern model in a vacuum pumping method. The charging sequence of a smelting furnace comprises heat-resistant steel, high-chromium iron, low-chromium iron, ferromanganese iron, silicon iron and ferro-molybdenum. The casting temperature is 1620+ / -5 DEG C. The casting time is 30-50 s. The casting method comprises the steps of conducting casting from a riser on the sidewall of the refining kettle; cleaning and putting a casting body into a heat treatment furnace to be heated at 1050-1100 DEG C and conducting heat preservation for 1.8-2.5 h; putting the casting body into an oil bath to be subjected to oil cooling; grinding theround edge of a kettle opening and removing the riser through machining; and finally detecting whether the refining kettle is qualified or not through ultrasonic waves and then conducting classification and warehousing. The refining kettle prepared through the method has the heat-resistant strength and good heat creep properties and corrosion resistance, and the using safety and reliability of the refining kettle can be greatly improved.

Owner:府谷县旭丽机电技术有限公司

High-temperature-resistant alloy elbow and processing technology thereof

PendingCN113294613AImprove mechanical propertiesImprove high temperature resistanceFireproof paintsCorrosion preventionManganeseCerium

The invention discloses a high-temperature-resistant alloy elbow and a processing technology thereof. The high-temperature-resistant alloy elbow comprises alloy raw materials, by mass, 0.02% of carbon, 0.1-0.15% of nitrogen, 1.3-1.5% of manganese, 20-21% of chromium, 10-12% of nickel, 0.2-0.5% of silicon, 1-1.3% of aluminum, 1.3-1.9% of zirconium, 1-2% of lanthanum, 2-3% of cerium, 0.3-0.8% of neodymium and the balance of iron. According to the formula, smelting and casting forming of an alloy matrix are carried out to obtain the alloy elbow, and the alloy elbow has excellent mechanical properties and high temperature resistance under the formula; and meanwhile, in the smelting process, ultrasonic treatment is carried out, the ultrasonic treatment conditions are limited to be that the ultrasonic power is 1-2kW, and the ultrasonic frequency is 20kHz, in the process, ultrasonic waves can generate the acoustic cavitation effect, local instantaneous high temperature and high pressure can be generated by alloy melt, the effects of dispersing the alloy phase and refining the alloy structure can be achieved, and the mechanical property and the high-temperature resistance of the alloy elbow can be effectively improved.

Owner:江苏龙山管件有限公司

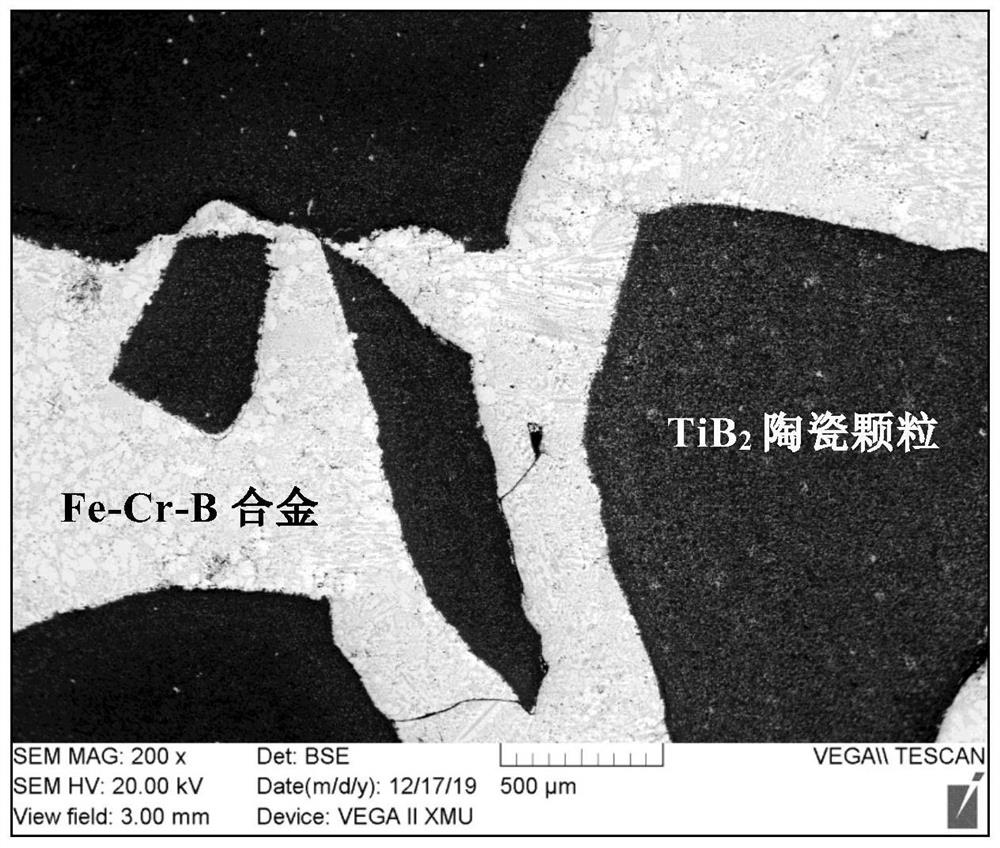

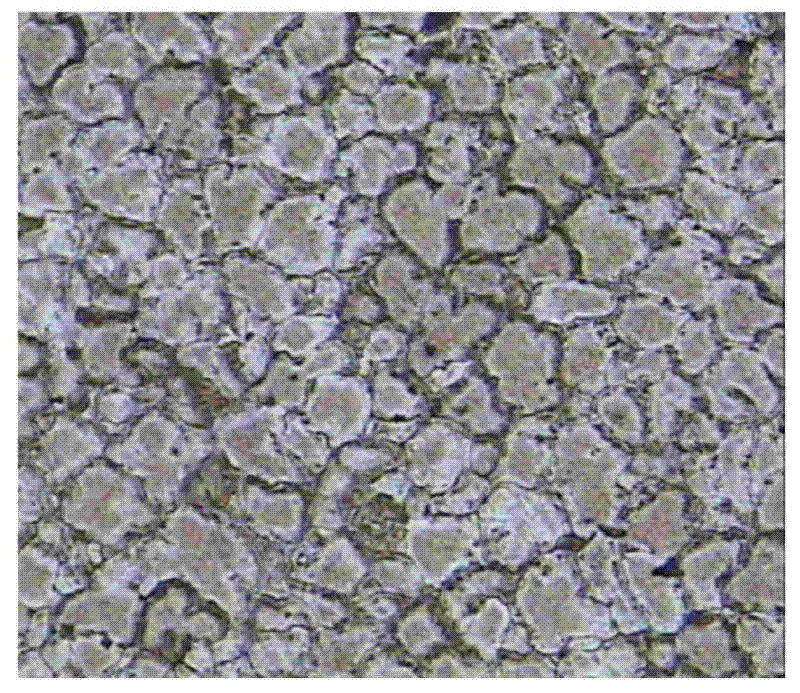

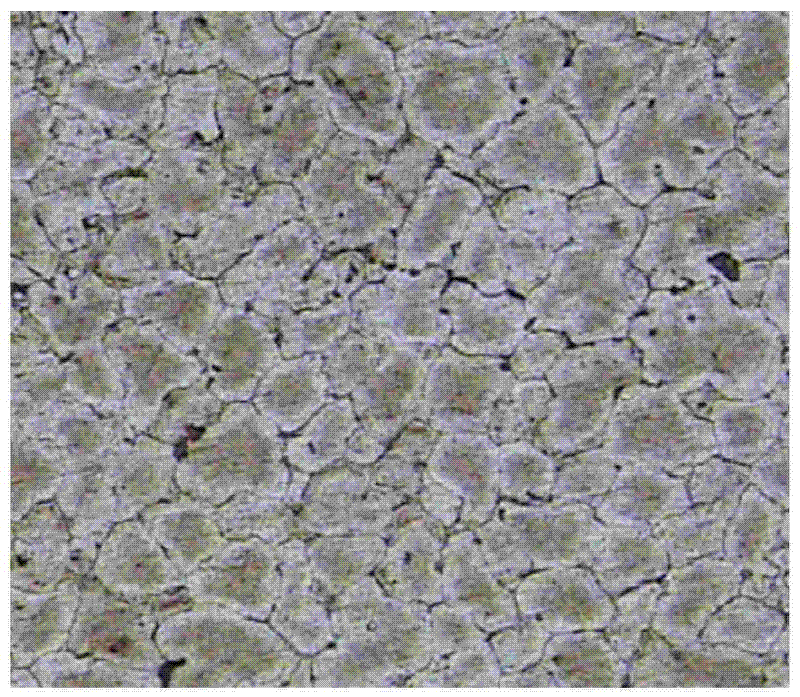

Preparation method of TiB2 reinforced Fe-Cr-B alloy-based composite lining plate

The invention discloses a preparation method of a TiB2 reinforced Fe-Cr-B alloy-based composite lining plate. The preparation method comprises the following steps that 1, TiB2 powder and Fe-Cr alloy powder are added into a polyvinyl alcohol solution, and the mixture is uniformly stirred to obtain a TiB2 ceramic blank; 2, pressing is conducted to obtain a TiB2 ceramic blank body; 3, vacuum sintering is conducted to obtain a TiB2 ceramic block; 4, the TiB2 ceramic block is crushed into TiB2 ceramic particles, then the TiB2 ceramic particles and Fe-Cr alloy powder are added into ethanol, uniformmixing is conducted, and vacuum sintering is conducted to obtain a prefabricated body; and 5, Fe-Cr-B alloy liquid is poured into the prefabricated body, and the composite lining plate is obtained. According to the preparation method, the bonding strength of the TiB2 ceramic particles and the internal interface of the Fe-Cr-B alloy-based composite lining plate is enhanced through the Fe-Cr alloy,the wear resistance of the composite lining plate is improved, the quality of the composite lining plate is improved, the surface treatment process is simplified, the preparation cost is reduced, andthe problem that the wear resistance of a material is affected due to poor bonding capacity of the ceramic particles and the interface of a matrix is solved.

Owner:XIAN UNIV OF SCI & TECH

A kind of high-strength aluminum plate for truck fuel tank and production method thereof

ActiveCN113862498BImprove corrosion resistanceInhibition of recrystallizationFurnace typesHeat treatment furnacesFuel tankIngot

The invention discloses a high-strength aluminum plate for a fuel tank of a truck and a production method thereof. In the present invention, pure aluminum ingots, pure magnesium ingots and pure zinc ingots are used as raw materials for smelting, and intermediate alloy ingredients are added for smelting, and the composition of the obtained alloy liquid satisfies the composition of its alloy elements; , hot rough rolling and hot finishing rolling to make aluminum alloy billet coils; the obtained coils are cold-rolled to obtain cold-rolled coils with two thicknesses of 2.5mm and 3.5mm; the obtained coils with a thickness of 2.5mm are sequentially annealed and cleaned. , to obtain an O state finished coil; the obtained cold-rolled coil with a thickness of 3.5 mm is sequentially subjected to intermediate annealing, secondary cold rolling, stabilization treatment and cleaning to obtain an H32 state finished coil. The product prepared by the method has excellent mechanical properties, corrosion resistance and stamping forming properties, and can effectively solve the technical problems of poor corrosion resistance and low elongation of fuel tanks of trucks that lead to stamping and cracking of fuel tanks.

Owner:河南泰鸿新材料有限公司

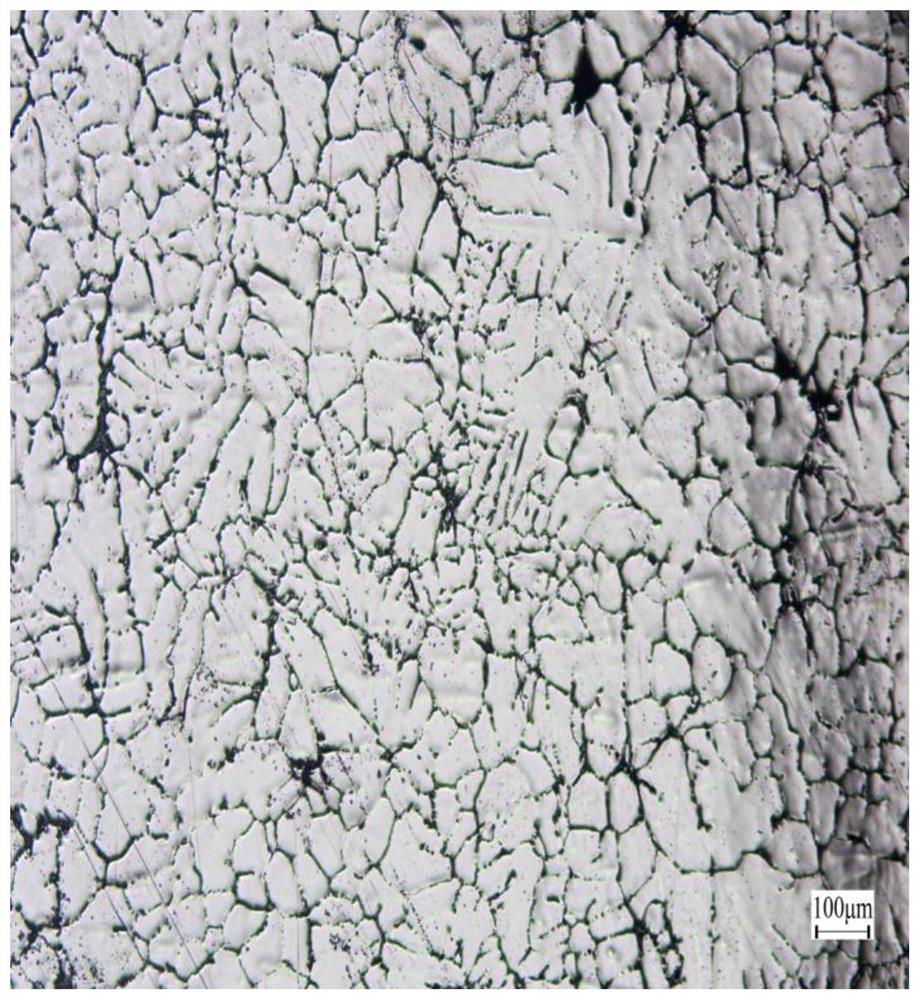

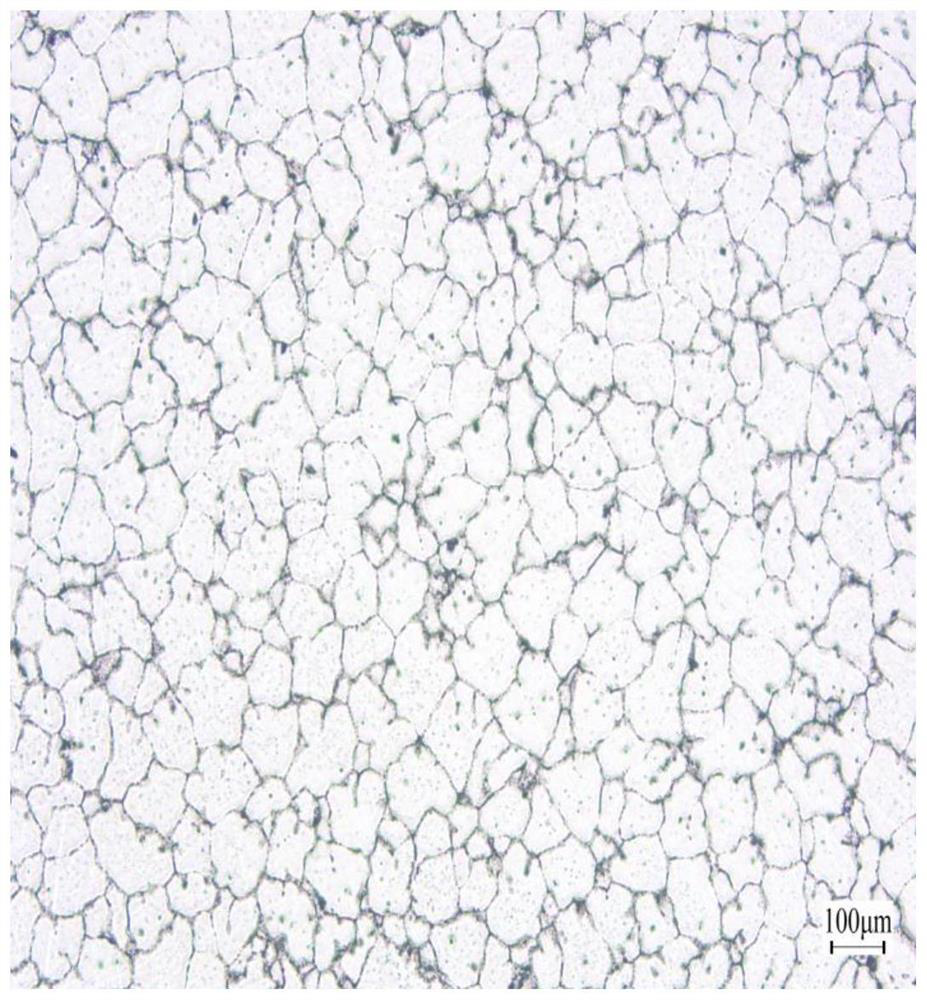

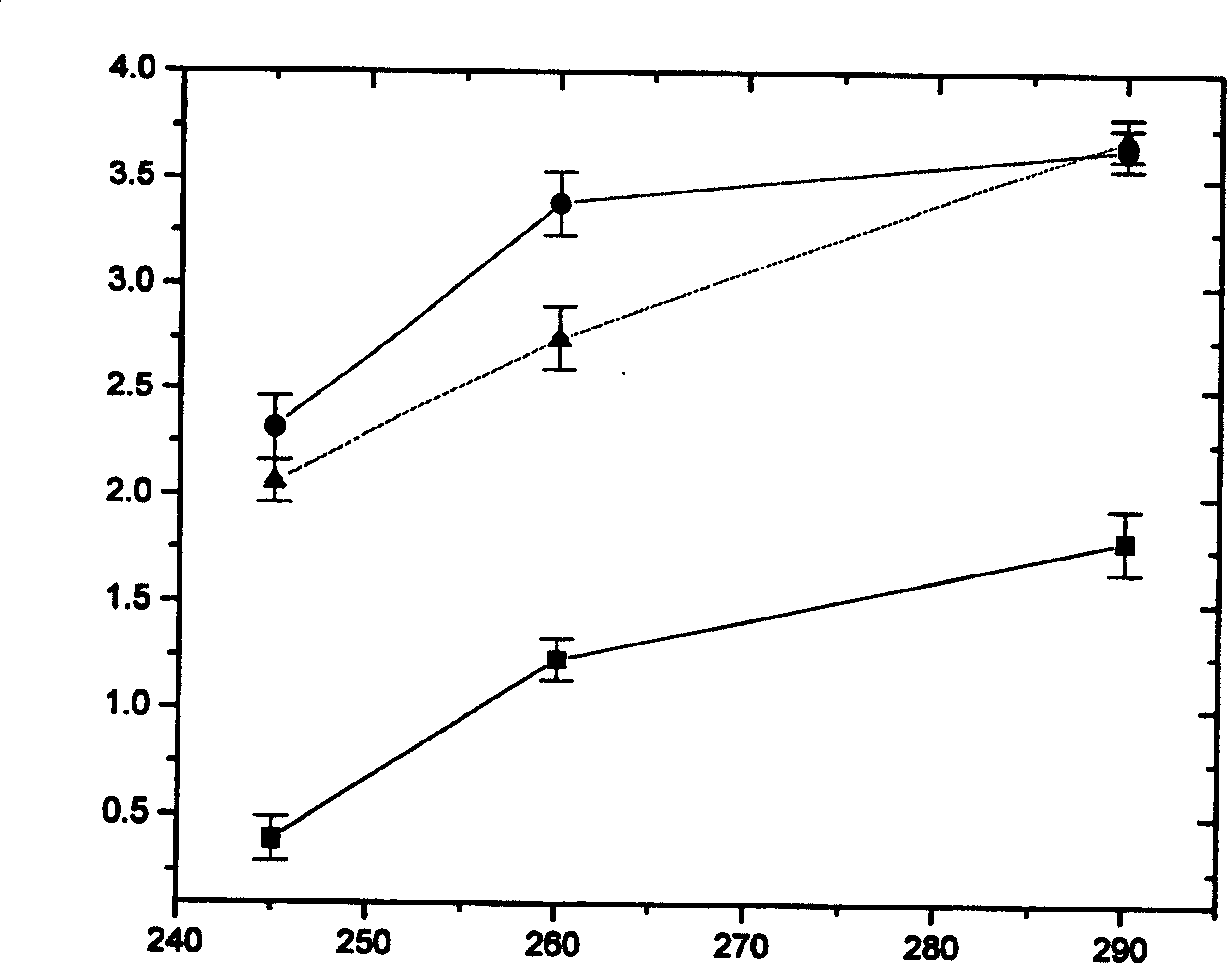

Preparation method of Al-5 percent Cu base alloy with low heat cracking tendency

The invention relates to a preparation method of an Al-5 percent Cu base alloy, in particular to a preparation method of an Al-5 percent Cu base alloy with low heat cracking tendency, solving the problems of wide crystallization temperature range and high heat cracking tendency of an Al-5 percent Cu base alloy prepared by the prior method. The preparation method comprises the following steps: (1)weighting the following raw materials: aluminum, an aluminum-copper master alloy, an aluminum-manganese master alloy, an aluminum-zirconium master alloy, an aluminum-vanadium master alloy, an aluminum-titanium-boron master alloy, cadmium and an aluminum-yttrium master alloy; (2) cleaning the surfaces of the raw materials and melting and casting the raw materials to obtain a chilled ingot; and (3)mixing, melting and casting the chilled ingot and the raw materials in the step (1) to obtain the Al-5 percent Cu base alloy. The Al-5 percent Cu base alloy achieves the tensile strength of 450-500N and the heat cracking resistance value of 670N which is higher than the heat cracking resistance value of the prior Al-5 percent Cu base alloy by 103 percent, thereby being more safely applied to the aerospace industry, the weapon industry and the nuclear industry.

Owner:HARBIN INST OF TECH

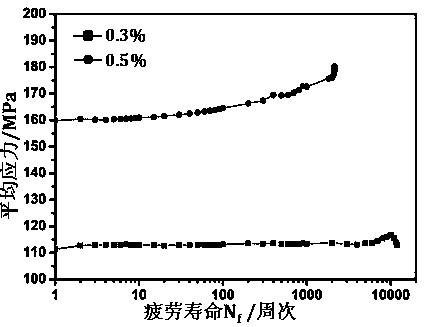

A method to improve the strength and strain fatigue life of aq80m magnesium alloy

Disclosed is a method for improving strength of an AQ80M magnesium alloy and prolonging strain fatigue life thereof, comprising the following steps: performing homogeneous annealing on an AQ80M semi-continuous casting ingot blank, and then performing multi-directional hammer cogging; and performing primary rolling on an obtained forging blank at the high temperature of 380-430°C, and then reducing the temperature to 150-330°C, and performing finish-rolling forming. According to the method, the high-temperature plastic advantage of the AQ80M magnesium alloy is fully played, so that the forming property of the alloy is improved, and substantial reduction of material plasticity and fatigue performance due to dynamic precipitation is avoided. Moreover, the finish-rolling temperature is reduced by rapid cooling, grains can be effectively refined, the material strength is improved, and the strain fatigue life is prolonged. The operation process is simple and practicable, and a prepared AQ80M magnesium alloy board has the yield strength of higher than or equal to 280 MPa and the tensile strength of higher than or equal to 350 MPa, the fatigue life is 10 4 times or more when the additional total strain amplitude is 0.3%, and the fatigue life is 2200 times or more when the additional total strain amplitude is 0.5%.

Owner:湖南镁宇科技有限公司

A heat-resistant and anti-corrosion metal magnesium refining pot and its preparation method

ActiveCN108950386BImprove heat resistanceImprove corrosion resistanceFurnace typesHeat treatment furnacesFerrosiliconThermal creep

The invention discloses a metallic magnesium refining kettle and a preparation method thereof. The metallic magnesium refining kettle is prepared through an evaporative pattern model in a vacuum pumping method. The charging sequence of a smelting furnace comprises heat-resistant steel, high-chromium iron, low-chromium iron, ferromanganese iron, silicon iron and ferro-molybdenum. The casting temperature is 1620+ / -5 DEG C. The casting time is 30-50 s. The casting method comprises the steps of conducting casting from a riser on the sidewall of the refining kettle; cleaning and putting a casting body into a heat treatment furnace to be heated at 1050-1100 DEG C and conducting heat preservation for 1.8-2.5 h; putting the casting body into an oil bath to be subjected to oil cooling; grinding theround edge of a kettle opening and removing the riser through machining; and finally detecting whether the refining kettle is qualified or not through ultrasonic waves and then conducting classification and warehousing. The refining kettle prepared through the method has the heat-resistant strength and good heat creep properties and corrosion resistance, and the using safety and reliability of the refining kettle can be greatly improved.

Owner:府谷县旭丽机电技术有限公司

Wrought magnesium alloy and preparation method thereof

The invention relates to wrought magnesium alloy, which comprises the following ingredients in percentage by weight: 6.15 percent to 6.84 percent of Al, 1.05 percent to 1.36 percent of Zn, 0.20 percent to 0.45 percent of Mn, 0.50 percent to 1.50 percent of Sc and the balance Mg. The invention also relates to a preparation method of the wrought magnesium alloy. The wrought magnesium alloy and the preparation method have the advantages that the rare earth element Sc is adopted for modification treatment on the wrought magnesium alloy, the effects of refining crystal grains and improving the alloy tissue can be reached, through mechanical performance detection, the intensity, the plasticity, the hardness and the toughness of the wrought magnesium alloy are all improved through being compared with those of the magnesium alloy without the rare earth element Sc, and the later period processing formation is favorably realized.

Owner:BYD CO LTD

Precipitation strengthening high-carbon austenitic heat-resistance steel and preparation method thereof

The invention discloses novel precipitation strengthening high-carbon austenitic heat-resistance steel. The steel comprises the following alloy components in percentage by mass: 0.5-0.8% of C, 24-28% of Cr, 35-50% of Ni, Co not more than 3.0%, Mn not more than 2.0%, 1.5-3.0% of Si, Nb not more than 1.0%, W not more than 7.5%, 0.5-2.5% of Ti, and the balance of Fe, wherein the Ti and Nb contents satisfy Ti / Nb not less than 0.7 and Ti+Nb not less than 2. An alloy prepared by the method eliminates coarse eutectic carbides in a cast-state alloy structure under the precondition of guaranteeing higher carbide volume fraction; and as a lot of (Nb, Ti) C are uniformly dispersed in the alloy to inhibit coarse growth of Cr23C6, the excellent effect on the alloy structure and the performance stability is achieved.

Owner:HUANENG POWER INT INC +1

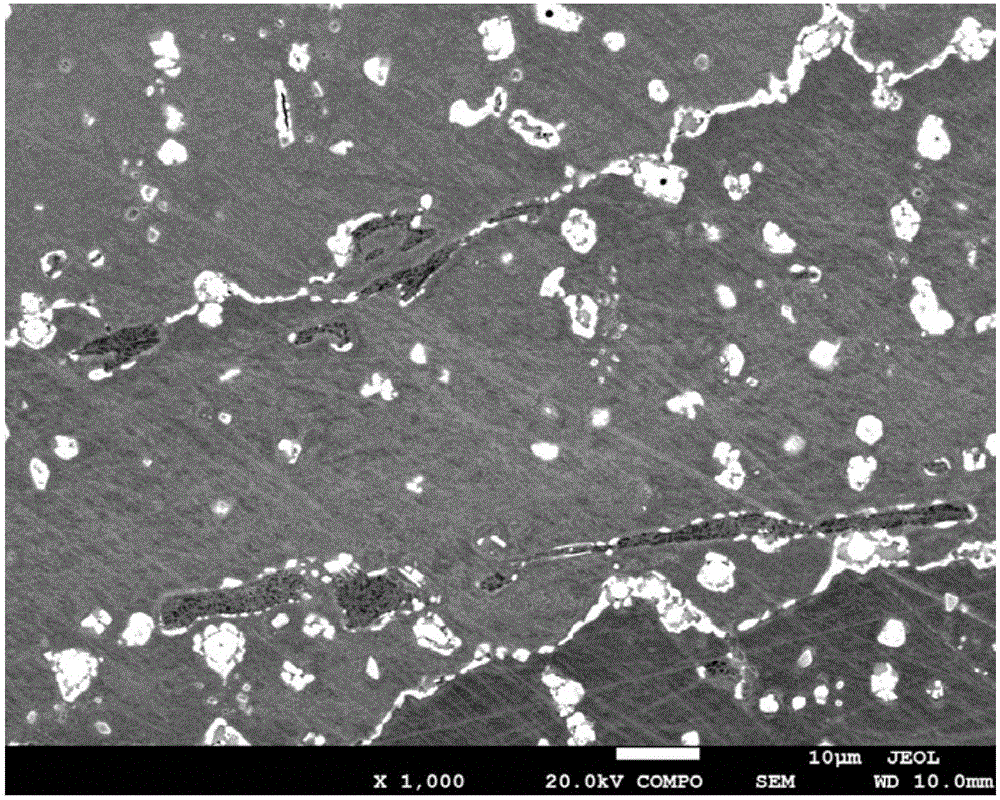

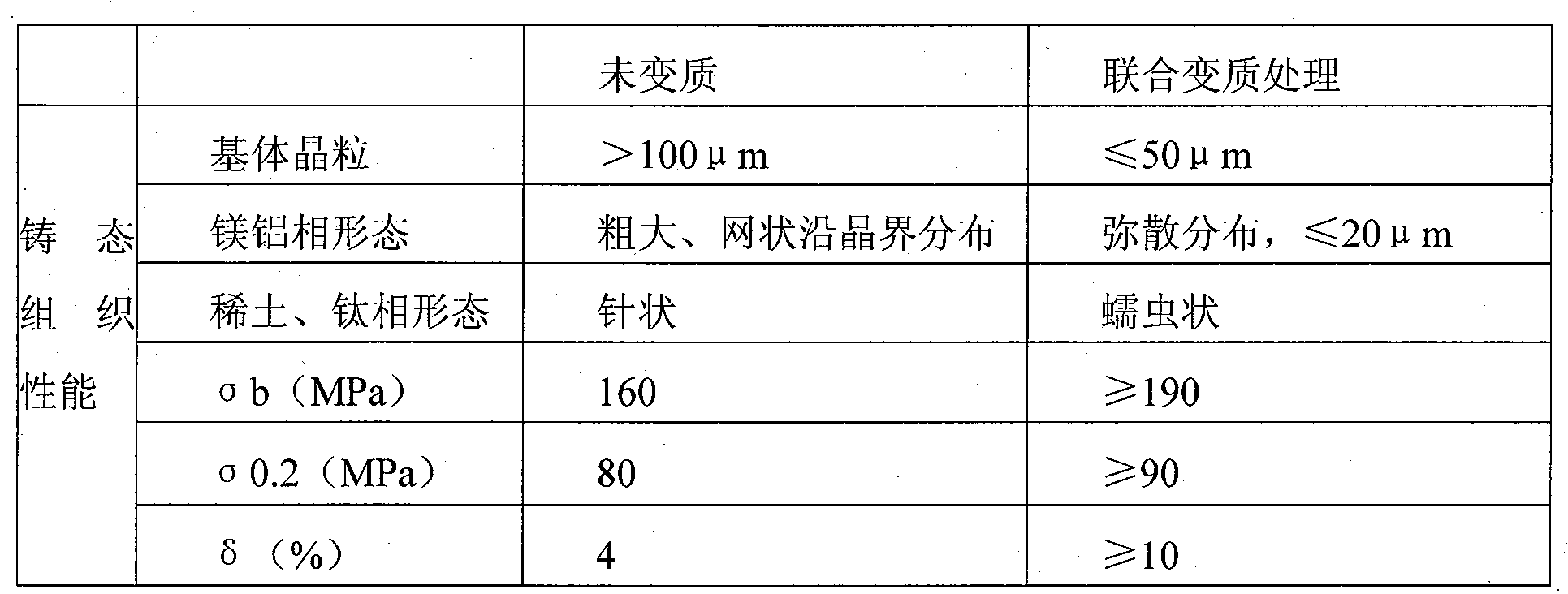

Titanium rare-earth magnesium alloy

The present invention provides a titanium rare earth magnesium alloy and its preparation method. The composition of said titanium rare earth magnesium alloy includes (by wt%) 1.0%-9.0% of aluminium, 1.0%-6.0% of zinc, 0.2%-3.0% of silicone, 0.5%-7.0% of manganese, 0.01%-15.0% of rare earth, 0.01%-3.0% of titanium, 0.0%-2.0% of zirconium and the rest is magnesium. Said titanium rare earth magnesium alloy has high strength, high toughness and good processability.

Owner:孙德春 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com