Low-lead brass alloy and preparing method thereof

A brass alloy and lead brass technology, applied in the field of brass alloy and its preparation, can solve the problems of inability to perform effective processing, poor air density, compactness and polishing performance of brass alloy, and achieve cutting performance and polishing effect. The effect of improving and refining the alloy structure and increasing the density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

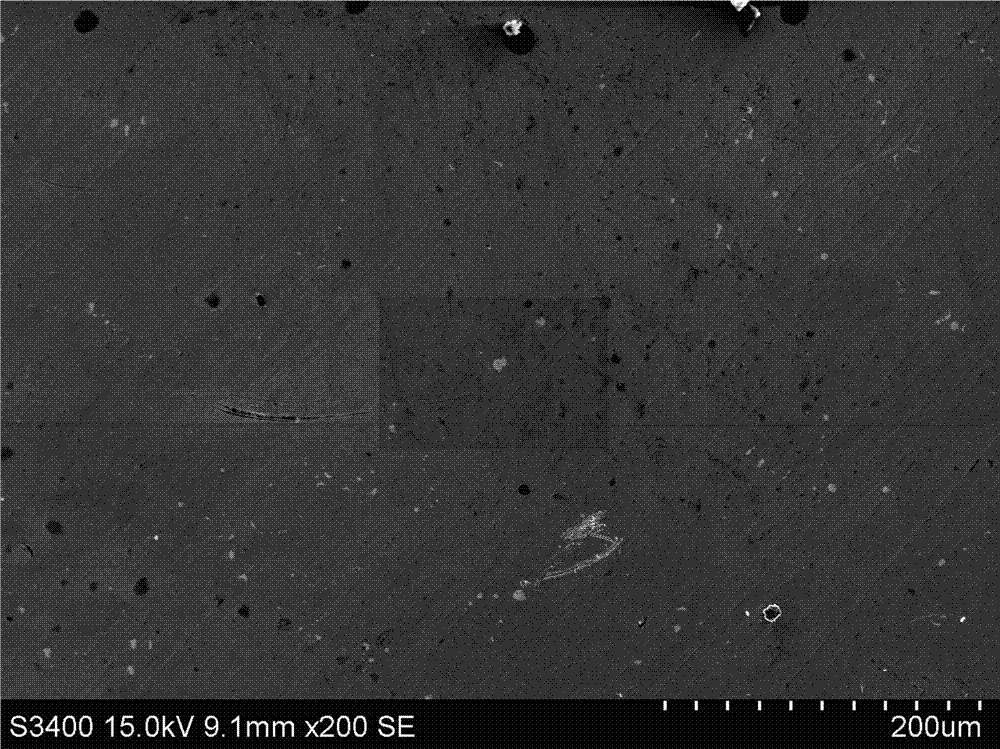

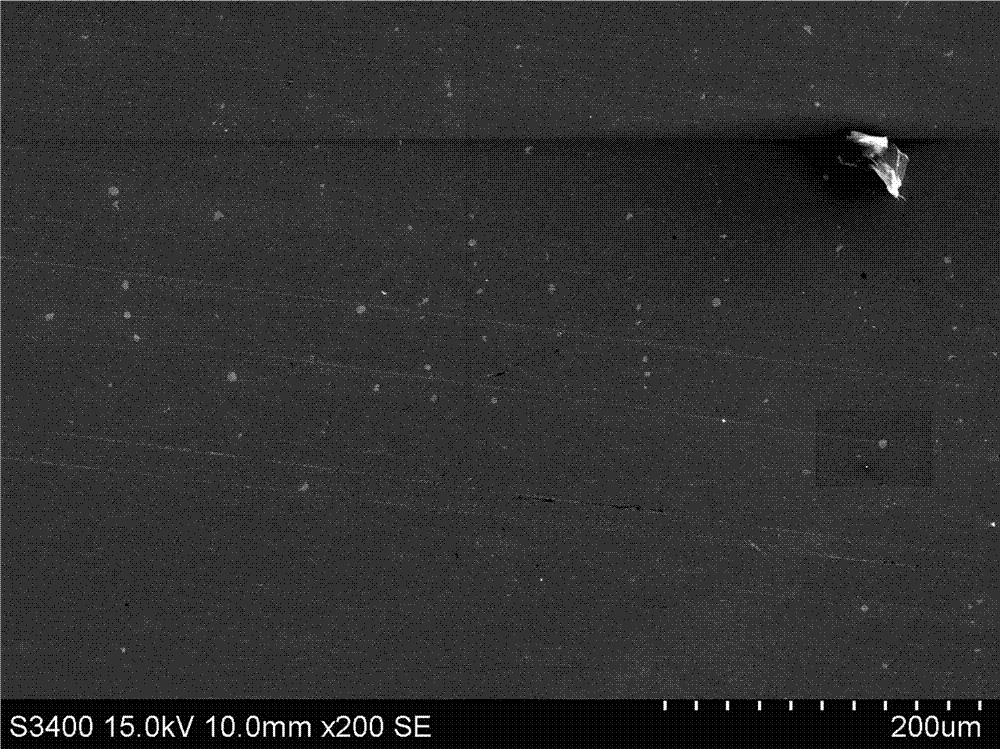

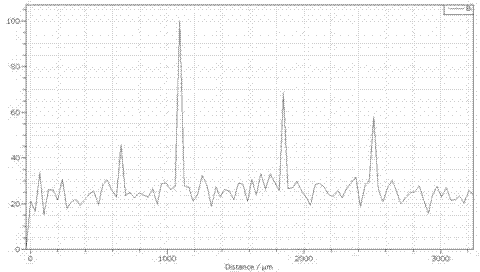

[0031] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

[0032] In this specification, the components contained in the low-lead brass alloy are based on the total weight of the alloy and expressed in weight percentage.

[0033] First, in the low-lead brass alloy of the present invention, the content of copper and zinc accounts for more than 96.5% by weight of the total alloy weight, wherein copper accounts for 59 to 63% by weight of the total alloy weight, preferably, copper accounts for 50% by weight of the total alloy weight 60.5 to 62% by weight, which can provide good toughness to facilitate subsequent processing of alloy materials.

[0034] Further, in the lead-free brass alloy of the present invention, the content of aluminum accounts for 0.4 to 0.7% by weight of the total weight of the alloy, preferably accounts for 0.5 to 0.6% by weight of the total weight of the alloy. Adding a specific amount of alum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com