Titanium rare-earth magnesium alloy

A rare earth magnesium and alloy technology, applied in the field of titanium rare earth magnesium alloy, can solve the problems of low potential of magnesium electrode, poor plasticity of magnesium alloy, poor corrosion resistance of magnesium, etc. Effect

Inactive Publication Date: 2010-08-25

孙德春 +1

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The electrode potential of magnesium is very low, and the electrochemical order ranks last among commonly used metals, so the corrosion resistance of magnesium is poor

It is easy to corrode in humid atmosphere, fresh water, sea water and most acid and salt solutions. Therefore, during the production, processing, storage and use of magnesium alloys, appropriate protective measures should be taken on the surface. Magnesium alloys are prone to corrosion when in contact with other metals. Contact corrosion; and conventional magnesium alloys have poor plasticity and low extrusion temperature, so extrusion is more difficult

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Login to View More

Abstract

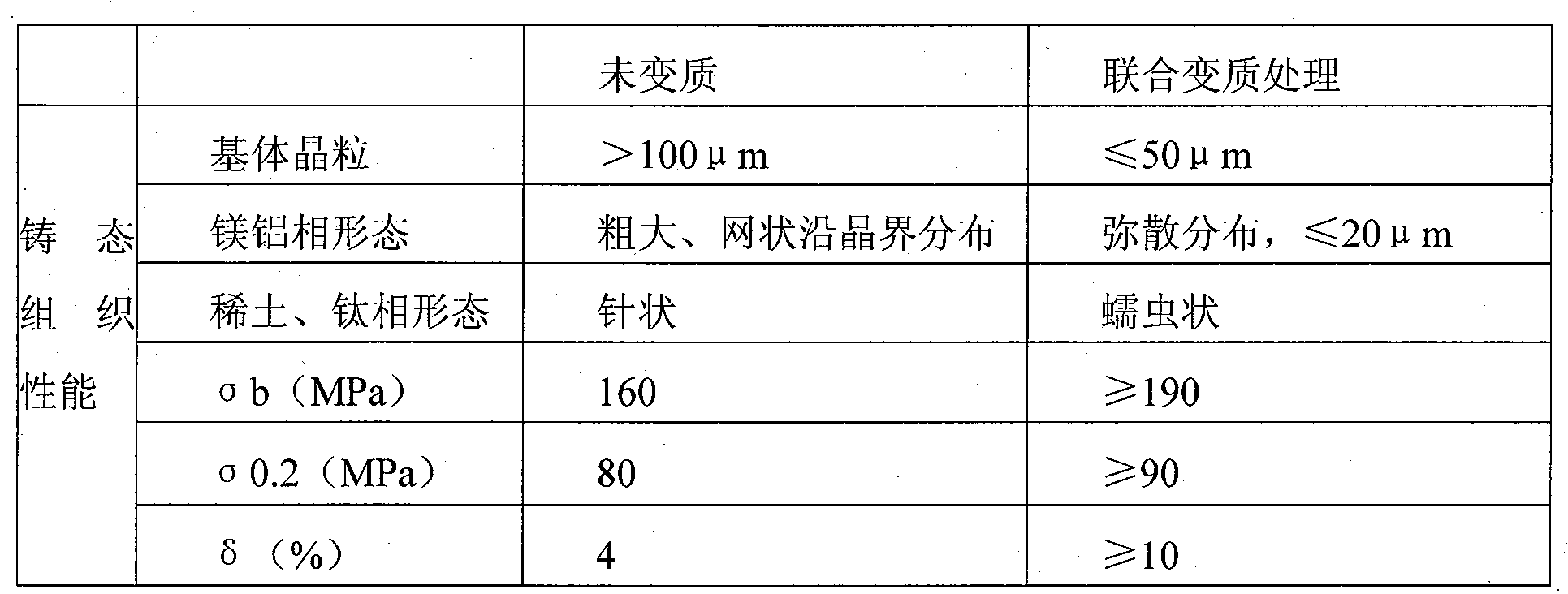

The present invention provides a titanium rare earth magnesium alloy and its preparation method. The composition of said titanium rare earth magnesium alloy includes (by wt%) 1.0%-9.0% of aluminium, 1.0%-6.0% of zinc, 0.2%-3.0% of silicone, 0.5%-7.0% of manganese, 0.01%-15.0% of rare earth, 0.01%-3.0% of titanium, 0.0%-2.0% of zirconium and the rest is magnesium. Said titanium rare earth magnesium alloy has high strength, high toughness and good processability.

Description

technical field A magnesium alloy, especially a corrosion-resistant titanium-containing rare earth magnesium alloy with good corrosion resistance, high strength, high toughness and good processing performance and a preparation method thereof. Background technique The density of magnesium alloy is 23% of steel, 67% of aluminum, and 170% of plastic. It is the lightest metal in metal structural materials. The yield strength of magnesium alloy is roughly equivalent to that of aluminum alloy, only slightly lower than that of carbon steel. It is plastic Its elastic modulus is 4-5 times higher than that of plastics, which is more than 20 times that of plastics. Therefore, under the same strength and rigidity, using magnesium alloys as structural parts can greatly reduce the weight of parts. The aviation industry, the automobile industry, and portable electronic devices are all of great significance. However, magnesium has strong chemical activity and is easy to oxidize in the air....

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22C23/00C22C1/03B22D21/04C22F1/06

Inventor 孙德春孟中

Owner 孙德春

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com