Wrought magnesium alloy and preparation method thereof

A technology of deformed magnesium alloy and magnesium alloy, which is applied in the field of metal materials, can solve the problems of poor plasticity, poor processing and forming performance, and insufficient comprehensive performance of deformed magnesium alloy, so as to achieve the improvement of hardness and toughness, which is beneficial to processing and forming, and refinement grain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

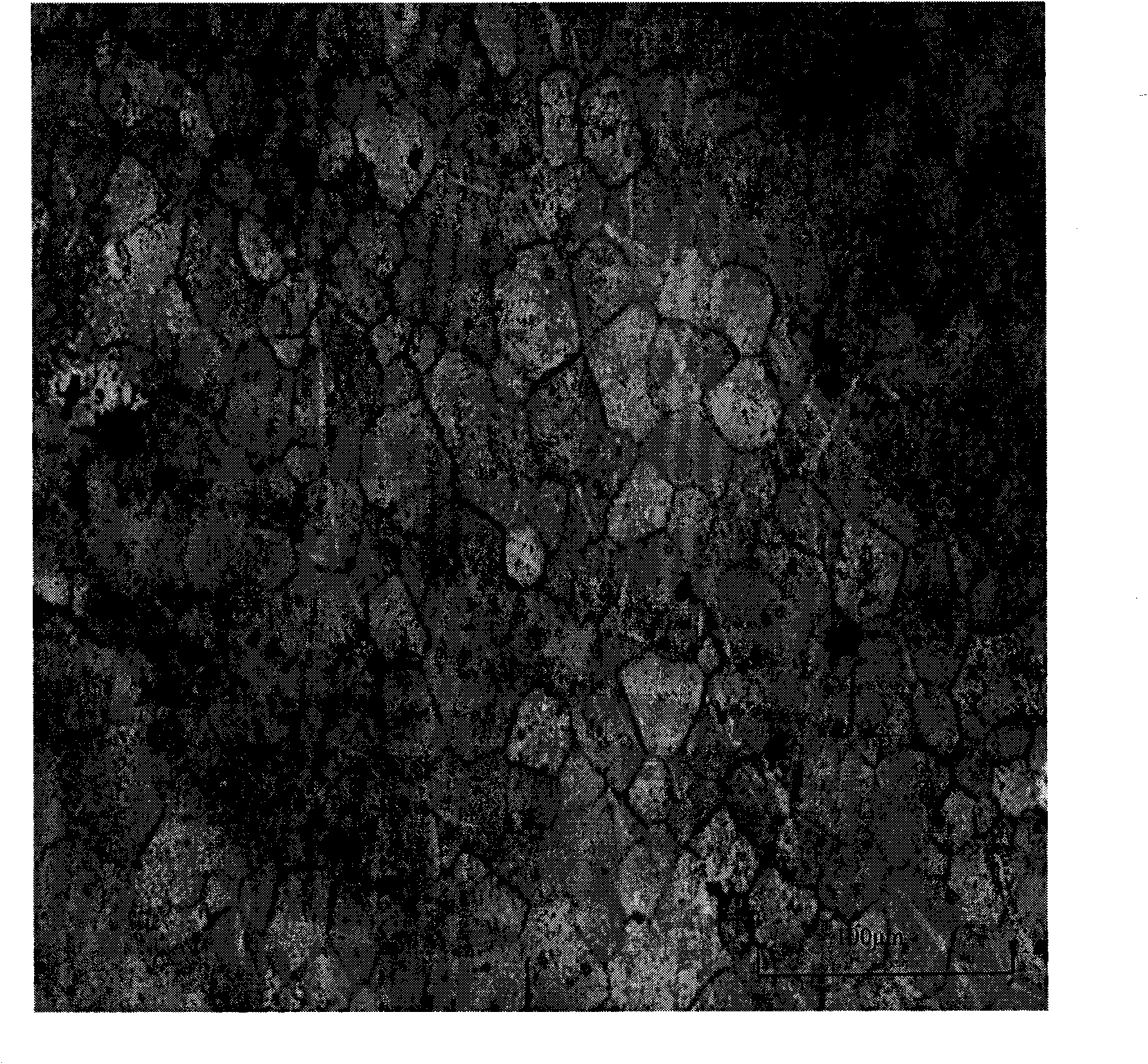

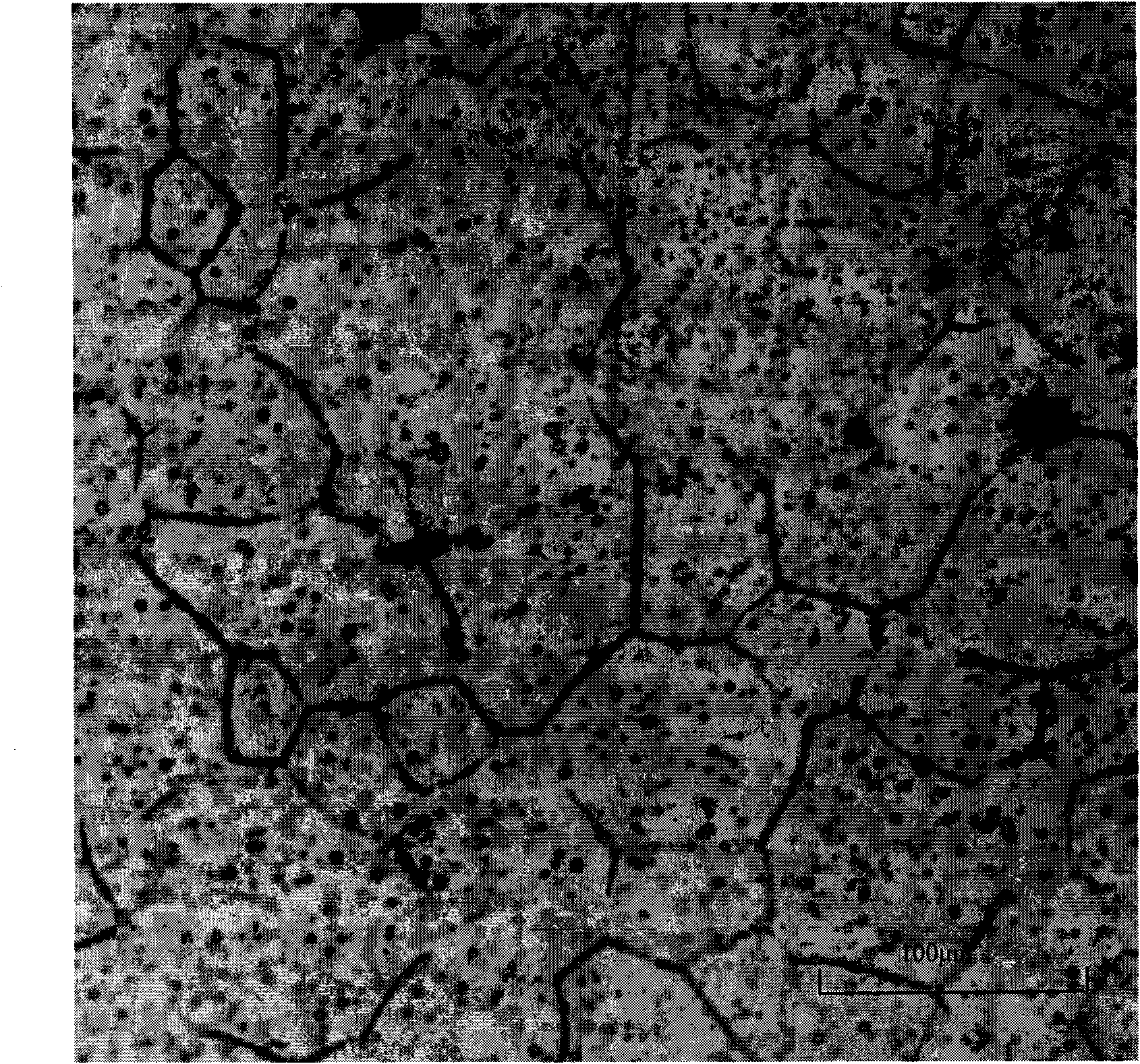

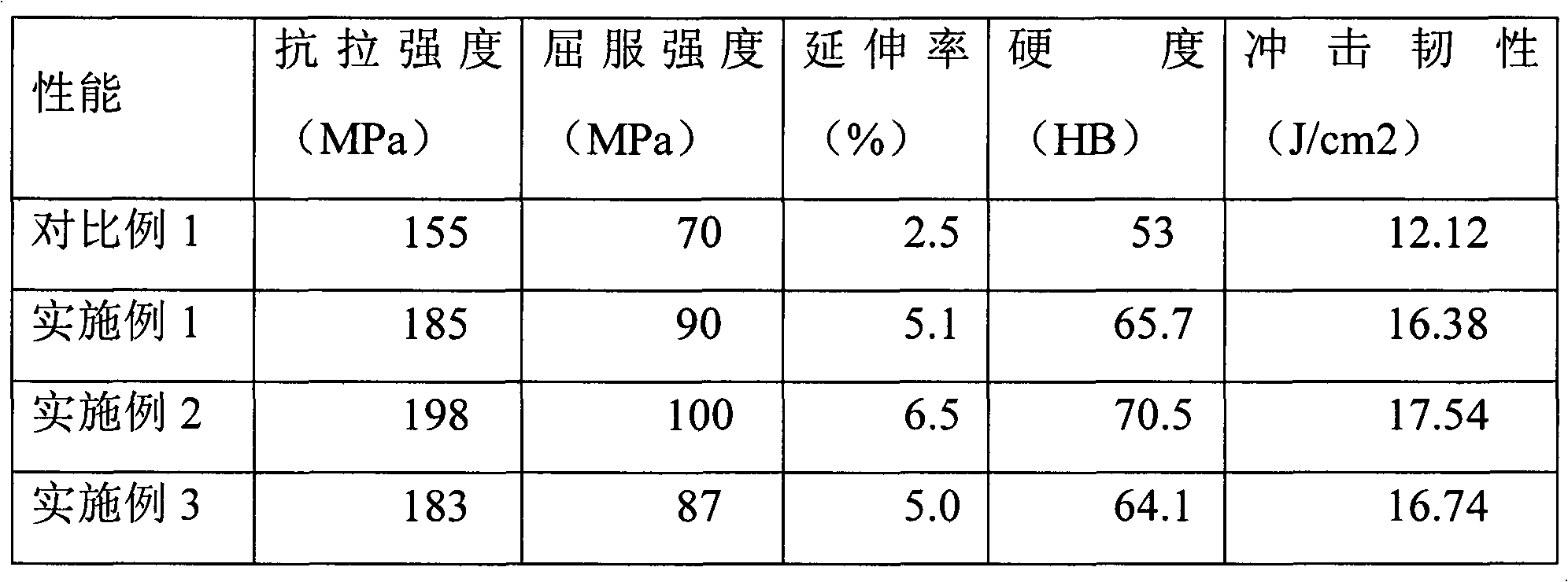

[0024] The preparation method of the deformed magnesium alloy of the present invention adopts the existing smelting process of material preparation→melt alloying→refining→casting to carry out magnesium alloy smelting to prepare the above deformed magnesium alloy, and then perform homogenization annealing at a temperature of 350-450°C for 8-14h After treatment, the grains are all fine equiaxed grains, with an average grain size of about 10-30 μm, and the grain size after subsequent extrusion into products can reach 1 μm. The steps in the preparation of wrought magnesium alloys are described in detail as follows:

[0025] Step 1, raw material preparation: 1) Raw materials: pure magnesium ingot (purity ≥ 99.9wt%), pure aluminum ingot (purity ≥ 99.9wt%), pure zinc ingot (purity ≥ 99.9wt%), (note: Unless otherwise specified, the alloy components used in the present invention are mass percent (wt%), aluminum-manganese master alloy ingot, and pure scandium ingot (purity ≥ 99.9wt%) an...

Embodiment 1

[0041] The preparation method of the wrought magnesium alloy of embodiment 1 of the present invention comprises the following steps:

[0042] 1. Drying: Prepare the prepared raw materials: magnesium ingot (purity ≥99.9wt%), aluminum ingot (purity ≥99.9wt%), zinc ingot (purity ≥99.9wt%), aluminum-manganese master alloy ingot, and scandium ingot (purity ≥ 99.9wt%) is dried, wherein magnesium ingots, aluminum ingots, and zinc ingots are dried at a temperature of 100°C, while aluminum-manganese master alloy ingots and scandium ingots are dried at a temperature of 150°C.

[0043] 2. Melting: During the whole melting process, continuously feed SF into the resistance crucible 6 Gas protection, first preheat the resistance crucible to 300 ° C, sprinkle an appropriate amount of refining agent RJ-5 and covering agent RJ-6 on the side wall and bottom of the crucible, and then put in the weighed magnesium ingots, aluminum ingots, zinc Ingot, continue heating, after the magnesium ingot, a...

Embodiment 2

[0045] The raw materials and preparation method are basically the same as those in Example 1, the only difference is that the addition of pure scandium ingot is 1wt%, and the magnesium alloy ingot A2 is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com