High-temperature-resistant alloy elbow and processing technology thereof

A high-temperature-resistant alloy and processing technology, which is applied in the coating process of metal materials, elbows, pipes/pipe joints/fittings, etc., can solve the problems of inconvenient practical application, unsatisfactory high-temperature resistance, and poor substrate bonding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

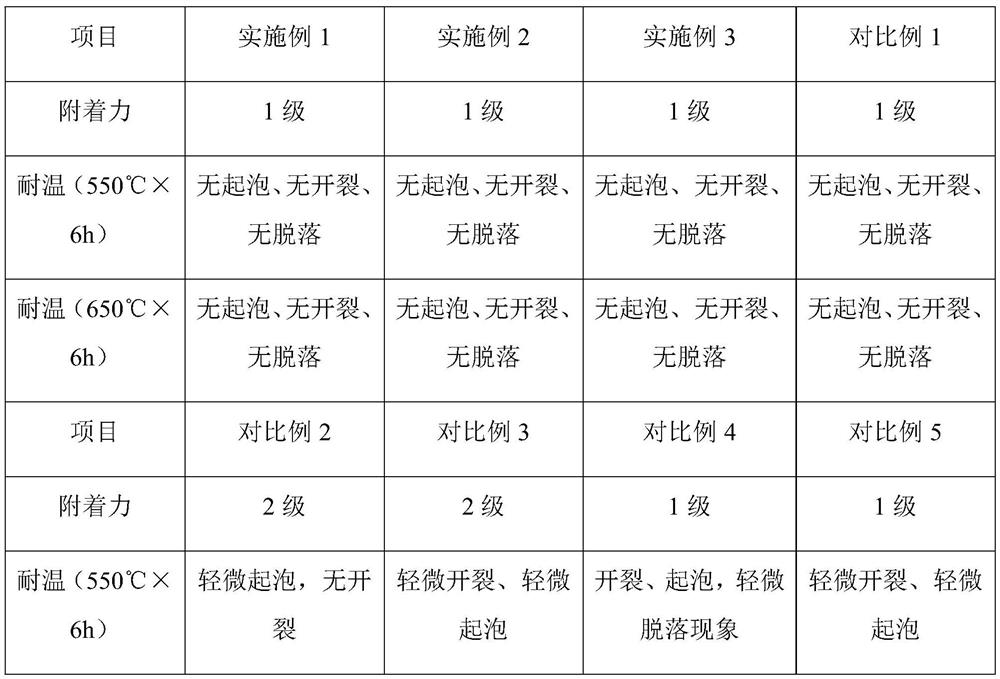

Examples

Embodiment 1

[0038] A processing technology for a high-temperature-resistant alloy elbow, comprising the following steps:

[0039] (1) Take the alloy raw materials, mix them and place them in a vacuum induction furnace for smelting. During smelting, ultrasonically treat the melt with an ultrasonic power of 1kW and an ultrasonic frequency of 20kHz. Cool and forge to obtain an alloy elbow;

[0040] Alloy raw materials include: by mass percentage, carbon 0.02%, nitrogen 0.1%, manganese 1.3%, chromium 20%, nickel 10%, silicon 0.2%, aluminum 1.3%, zirconium 1.9%, lanthanum 2%, cerium 3%, neodymium 0.8%, the balance is iron.

[0041] (2) Take the alloy elbow, place it in acetone solution, clean it ultrasonically for 5 minutes, then wash it with absolute ethanol and deionized water in sequence, and dry it in vacuum; after drying, the surface is cleaned by laser, the laser power is 15W, and the pulse frequency is 600kHz , the scanning speed is 50mm / s, and the laser spot diameter is 70um;

[0042...

Embodiment 2

[0052] A processing technology for a high-temperature-resistant alloy elbow, comprising the following steps:

[0053] (1) Take the alloy raw materials, mix them and place them in a vacuum induction furnace for smelting. During smelting, ultrasonically treat the melt with an ultrasonic power of 2kW and an ultrasonic frequency of 20kHz, cool and forge to obtain an alloy elbow;

[0054] Alloy raw materials include: by mass percentage, carbon 0.02%, nitrogen 0.15%, manganese 1.4%, chromium 21%, nickel 11%, silicon 0.3%, aluminum 1.2%, zirconium 1.5%, lanthanum 1.5%, cerium 2.5%, neodymium 0.5%, the balance is iron.

[0055] (2) Take the alloy elbow, place it in an acetone solution, and ultrasonically clean it for 8 minutes, then wash it with absolute ethanol and deionized water in sequence, and dry it in vacuum; after drying, the surface is cleaned by laser, the laser power is 15W, and the pulse frequency is 600kHz , the scanning speed is 80mm / s, and the laser spot diameter is 70...

Embodiment 3

[0066] A processing technology for a high-temperature-resistant alloy elbow, comprising the following steps:

[0067] (1) Take the alloy raw materials, mix them and place them in a vacuum induction furnace for smelting. During smelting, ultrasonically treat the melt with an ultrasonic power of 2kW and an ultrasonic frequency of 20kHz, cool and forge to obtain an alloy elbow;

[0068] Alloy raw materials include: by mass percentage, carbon 0.02%, nitrogen 0.15%, manganese 1.5%, chromium 21%, nickel 12%, silicon 0.5%, aluminum 1%, zirconium 1.3%, lanthanum 1%, cerium 2%, neodymium 0.3%, the balance is iron.

[0069] (2) Take the alloy elbow, place it in acetone solution, clean it ultrasonically for 10 minutes, then wash it with absolute ethanol and deionized water in turn, and dry it in vacuum; after drying, the surface is cleaned by laser, the laser power is 15W, and the pulse frequency is 600kHz , the scanning speed is 100mm / s, and the laser spot diameter is 70um;

[0070] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com