A method to improve the strength and strain fatigue life of aq80m magnesium alloy

A fatigue life, magnesium alloy technology, applied in the field of improving the strength and strain fatigue life of magnesium alloys, can solve the problems of low strength, reduce plasticity and fatigue performance, etc., achieve large plastic deformation, improve formability, and uniform structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

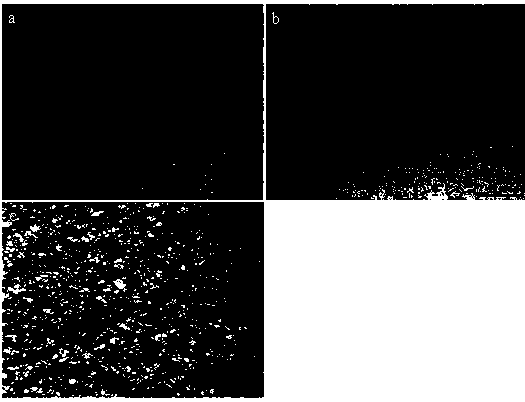

Image

Examples

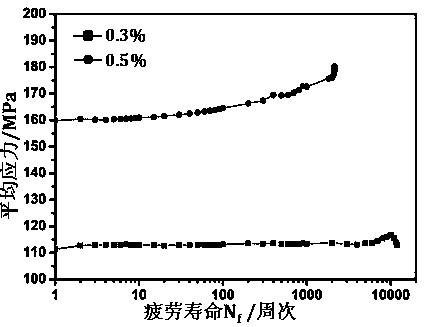

Embodiment 1

[0028] Semi-continuously cast AQ80M magnesium alloy ingots were air-cooled to room temperature after 250°C / 10h + 420°C / 40h double-stage homogenization treatment, and processed into rectangular parallelepiped samples by car descaling. Before multi-directional forging, put the ingot into the annealing furnace and heat it at 410°C for 4 hours, heat the upper and lower flat anvils to 300°C, and perform one-fire forging on the cuboid sample on the hydraulic press: take the length of the sample as Z, and the rest The two directions are arbitrary Y and X directions, and the compression is carried out in the order of Z-Y-X-Z-Y-X. The reduction speed is 200-400 mm / min, and the reduction amount per pass is 15%-25%. Cut the forging billet into 40 mm × 80 mm × 180 mm plates, hold it at 400 °C for 2.5 h, and roll it for 6 passes with twin rolls. The rolls are preheated to 200 °C in advance, and the reduction in each pass is 10%-20% , and return to the furnace for annealing between each pas...

Embodiment 2

[0030]Semi-continuously cast AQ80M magnesium alloy ingots were air-cooled to room temperature after 250°C / 10h + 420°C / 40h double-stage homogenization treatment, and processed into rectangular parallelepiped samples by car descaling. Before multi-directional forging, put the ingot into the annealing furnace and heat it at 400°C for 4 hours, heat the upper and lower flat anvils to 280°C, and perform one-fire forging on the cuboid sample on the hydraulic press: take the length of the sample as Z, and the rest The two directions are arbitrary Y and X directions, and the compression is carried out in the order of Z-Y-X-Z-Y-X. The reduction speed is 200-400 mm / min, and the reduction amount per pass is 15%-25%. Cut the forging billet into 40 mm × 80 mm × 180 mm plates, hold it at 410 °C for 2 h, and double-roll rolling for 6 passes. The rolls are preheated to 200 °C in advance, and the reduction in each pass is 10% to 20%. , annealing in the furnace between each pass, the annealing t...

Embodiment 3

[0032] Semi-continuously cast AQ80M magnesium alloy ingots were air-cooled to room temperature after 250°C / 10h + 420°C / 40h double-stage homogenization treatment, and processed into rectangular parallelepiped samples by car descaling. Before multi-directional forging, put the ingot into the annealing furnace and heat it at 400°C for 4 hours, heat the upper and lower flat anvils to 280°C, and perform one-fire forging on the cuboid sample on the hydraulic press: take the length of the sample as Z, and the rest The two directions are arbitrary Y and X directions, and the compression is carried out in the order of Z-Y-X-Z-Y-X. The reduction speed is 200-400 mm / min, and the reduction amount per pass is 15%-25%. The forging billet was cut into 40 mm × 80 mm × 180 mm plates, held at 410 °C for 2.5 h, and rolled by twin rolls for 6 passes, the rolls were preheated to 200 °C in advance, and the reduction in each pass was 10% to 20% , annealing in the furnace between each pass, the annea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com