Air conditioner foil and preparation method thereof

An air-conditioning foil, casting and rolling technology, which is applied in the field of aluminum foil calendering manufacturing, can solve the problems of insufficient strength of the alloy material, feeding of flanging cracks, and easy cracking, etc., achieve good lubrication effect, increase the height of flanging, and avoid flanging cracking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The invention relates to an air conditioner foil and a preparation method thereof. Firstly, its composition and mass percentage are controlled as follows: Si 0.25%, Fe 1.45%, Cu 0.012%, Mn 0.52%, Zn 0.0085%, Ti 0.016%, and the balance is Al.

[0025] According to the above composition control, further obtain the air-conditioning foil finished base material, the specific preparation steps are as follows:

[0026] (1) Smelting: The raw materials are fully stirred evenly during smelting, the smelting temperature is 755°C, the special refining agent is refined at 730°C for 20 minutes, and at 740°C for 20 minutes, and the composition is adjusted to meet the control requirements of the present invention. ℃;

[0027] (2) Casting and rolling: during casting and rolling production, the temperature of the filter box is controlled at 725°C, the pressure of argon gas is controlled at 0.2Mpa, and the gas flow rate is controlled at 2.0m 3 / h, rotor speed control 260rpm, filter box ...

Embodiment 2

[0033] The invention relates to an air-conditioning foil and a preparation method thereof. Firstly, its composition and mass percentage are controlled to be 0.26% Si, 1.5% Fe, 0.013% Cu, 0.57% Mn, 0.01% Zn, 0.018% Ti, and the balance is Al .

[0034] The subsequent processing technology of the cast-rolled aluminum coil base material is the same as that in the embodiment 1, and the finished air-conditioning foil is produced.

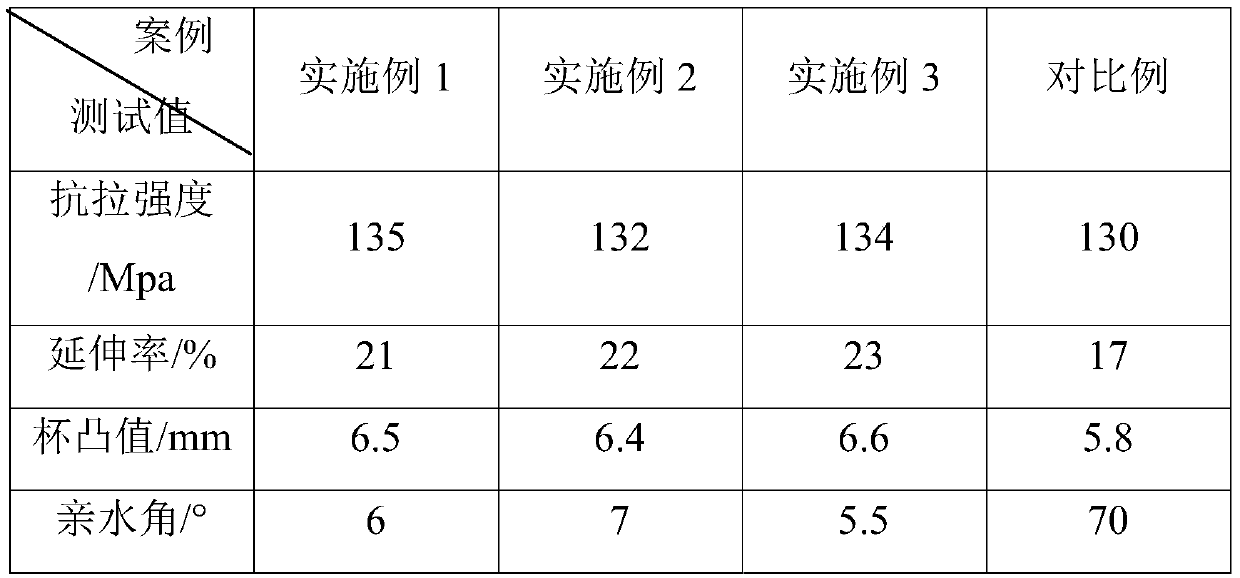

[0035] The performance test of the finished high-performance air-conditioning foil of the present invention shows that the tensile strength is 132Mpa, the elongation is 22%, the cup convex value is 6.4mm, and the hydrophilic angle is 7°. To meet the requirements of high-speed punch.

Embodiment 3

[0037] The invention relates to an air-conditioning foil and a preparation method thereof. Firstly, its composition and mass percentage are controlled to be 0.24% Si, 1.50% Fe, 0.016% Cu, 0.56% Mn, 0.009% Zn, 0.015% Ti, and the balance is Al .

[0038] The subsequent processing technology of the cast-rolled aluminum coil base material is the same as that in the embodiment 1, and the finished air-conditioning foil is produced.

[0039] The performance test of the above-mentioned high-performance air-conditioning foil finished product of the present invention shows that the tensile strength is 134Mpa, the elongation is 23%, the cup convex value is 6.6mm, and the hydrophilic angle is 5.5°. To meet the requirements of high-speed punch.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com