High-performance aluminum alloy and preparation method thereof

An aluminum alloy, high-performance technology, applied in the field of aluminum alloy materials, can solve the problems of long time required for transfer, long solution time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

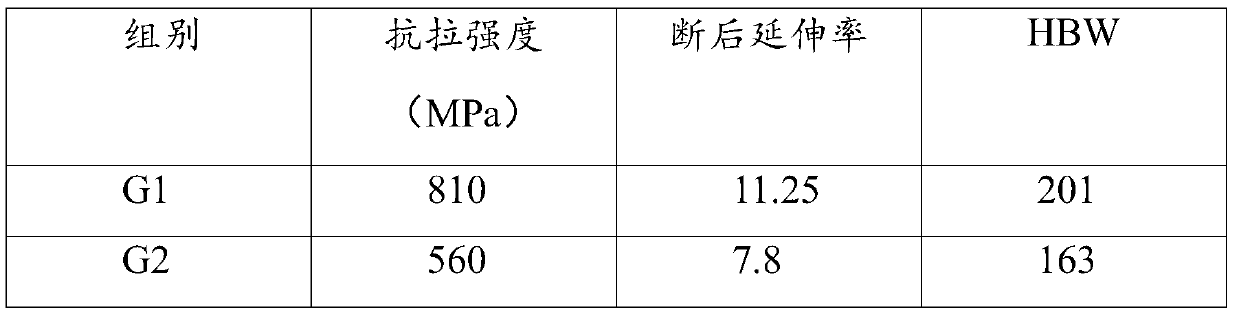

[0036] Al made of 56% 7075 aluminum ingots and 44% waste aluminum products, according to the mass percentage content of each alloy composition: 11.5% Zn, 1.8% Mg, 2.0% Cu, 0.15% Ce, 0.11% W, 0.08% Zr, 0.14 %Cr, 0.05%Mn, 0.02%Ti, 0.01%Fe, 0.03%Si prepared two groups of raw materials, and then divided them into two groups of G1 and G2 for comparison. The preparation method of G1 is prepared according to the steps of processing waste aluminum products-melting-spray forming-homogenization treatment-multi-pass rolling deformation-solution treatment-hot stamping treatment-aging treatment, that is, G1 The specific steps are:

[0037] S1: Clean the waste aluminum products with an aluminum material cleaning agent, and then dry them to obtain the above-mentioned waste aluminum products with a weight of 44%, and then carry out smelting, spray forming, homogenization treatment, and multi-pass rolling deformation. An aluminum alloy plate is obtained.

[0038] S2: Solution treatment: The ...

Embodiment 2

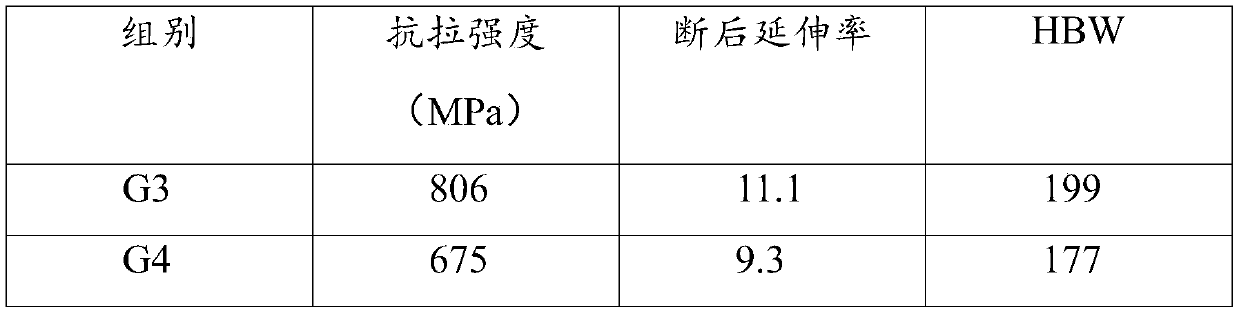

[0046]Al made of 56% 7075 aluminum ingots and 44% waste aluminum products, according to the mass percentage content of each alloy composition: 12.1% Zn, 1.8% Mg, 1.8% Cu, 0.19% Ce, 0.13% W, 0.15% Zr, 0.21 %Cr, 0.23%Mn, 0.04%Ti, 0.01%Fe, 0.03%Si prepared two groups of raw materials, and then divided them into two groups of G3 and G4 for comparison. The preparation method of G3 group is prepared according to the steps of processing waste aluminum products--smelting--spray forming--homogenization treatment--multi-pass rolling deformation--solution treatment--hot stamping treatment--aging treatment, etc., namely The specific steps of G3 are:

[0047] S1: Clean the waste aluminum products with an aluminum material cleaning agent, and then dry them to obtain the above-mentioned waste aluminum products with a weight of 44%, and then carry out smelting, spray forming, homogenization treatment, and multi-pass rolling deformation. An aluminum alloy plate is obtained.

[0048] S2: Solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com