High-strength aluminum plate for truck fuel tank and production method therefor

A technology for trucks and production methods, applied in furnaces, heat treatment equipment, manufacturing tools, etc., can solve problems such as stamping and cracking of fuel tanks, poor corrosion resistance, and poor corrosion resistance of fuel tanks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

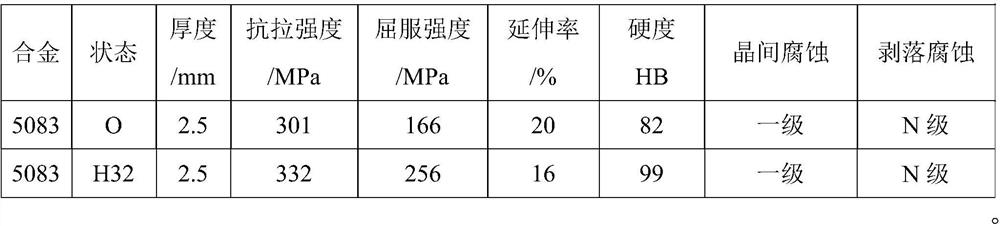

Embodiment 1

[0036] The high-strength aluminum sheet for the truck fuel tank of the present invention is represented by mass percentage, and its alloy element composition is: Mg 4.4%, Ta 0.205%, Si 0.117%, Fe 0.294%, Cu 0.042%, Mn 0.504%, Cr 0.121%, Zn 0.063%, Ti 0.018%, and Na 0.0001%, and the balance is Al.

Embodiment 2

[0038] The production method of the high-strength aluminum sheet for the truck fuel tank described in Embodiment 1 of the present invention, the detailed steps of the production method are as follows:

[0039] a. Melting: Use pure aluminum ingots, pure magnesium ingots and pure zinc ingots as raw materials for batch smelting. During the smelting process, control the smelting temperature to 735-750°C, and the smelting holding time is 25 minutes; add intermediate alloys Al-5Ta and Al during the smelting process -20Si, Al-5Fe, Al-50Cu, Al-20Mn, Al-5Cr and Al-5Ti-B carry out batching smelting, batching temperature is 740~750 ℃; Composition of alloying elements of high-strength aluminum sheets for truck fuel tanks;

[0040] b. Refining: Refining the alloy liquid obtained in step a, controlling the refining temperature to 730-735°C during the refining process, and the refining time is 40 minutes; after the refining is finished, let it stand still for 35 minutes;

[0041] Ar used in...

Embodiment 3

[0060] The high-strength aluminum sheet for the truck fuel tank of the present invention is represented by mass percentage, and its alloy element composition is: Mg 4.504%, Ta 0.211%, Si 0.139%, Fe 0.288%, Cu 0.041%, Mn 0.518%, Cr 0.126%, Zn 0.040%, Ti 0.020%, Na 0.0001%, and the balance is Al.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com