Rare earth aluminum alloy bar for forging aluminum alloy hub and preparation method of rare earth aluminum alloy bar

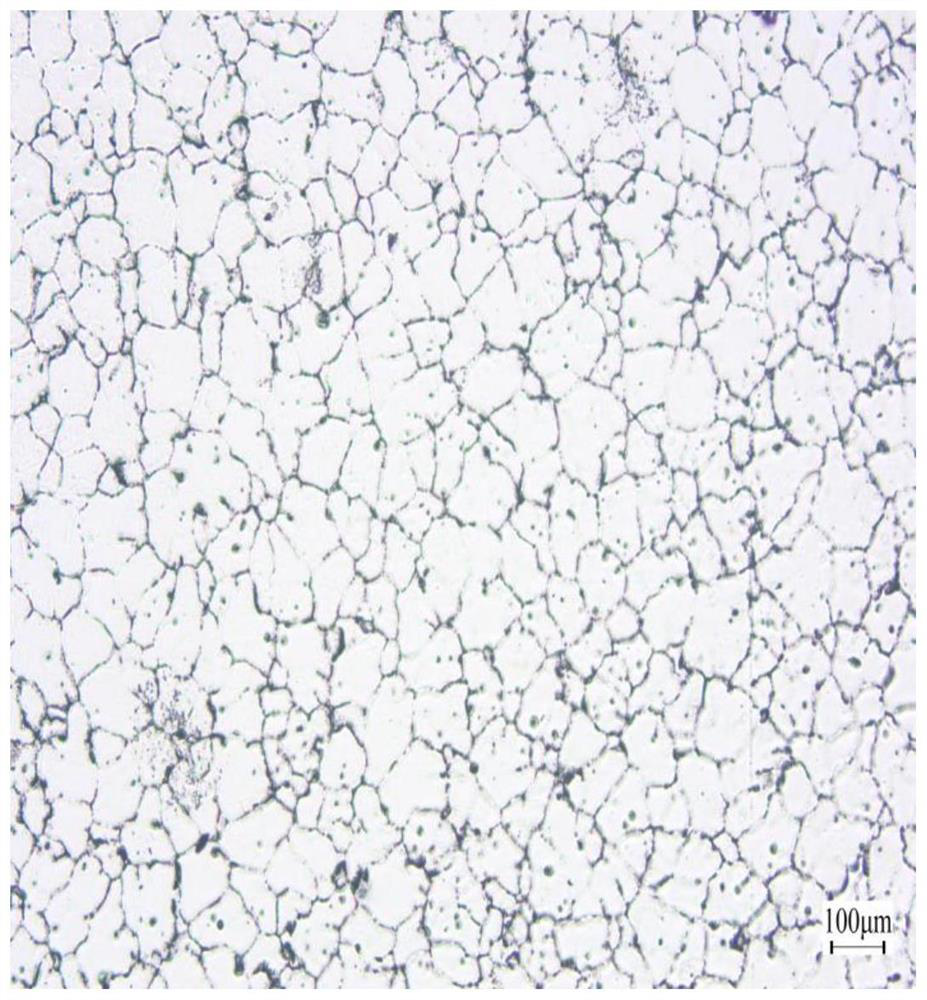

A technology of aluminum alloy wheel hub and aluminum alloy, which is applied in the field of 6061 rare earth aluminum alloy bar for forging aluminum alloy wheel hub and its preparation field, can solve the problems of reduced extrusion speed, increased extrusion force, decreased die life, etc., and achieves strength and The effect of improving plasticity, reducing splitting effect and restraining grain growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] A method for preparing a rare earth aluminum alloy bar for forging an aluminum alloy wheel hub, the specific steps are as follows:

[0038] Step 1: preparing an aluminum-lanthanum-cerium master alloy;

[0039] Step 11: Heat the aluminum metal (industrial pure aluminum) in an intermediate frequency induction furnace. After it is completely melted, continue heating to 830-850°C and keep the temperature stable;

[0040] Step 12: adding a certain proportion of mixed rare earth metal lanthanum cerium to the aluminum liquid, and keeping it warm (for half an hour) after the rare earth metal lanthanum cerium is completely melted, and degassing and removing slag after the heat preservation;

[0041] Step 13: After degassing and slag removal, lower the temperature of the melt to 750-800° C. and keep the temperature constant. After standing still for 5 minutes, pour it into a metal mold to obtain an ingot of an aluminum-lanthanum-cerium master alloy.

[0042] In the aluminum-lant...

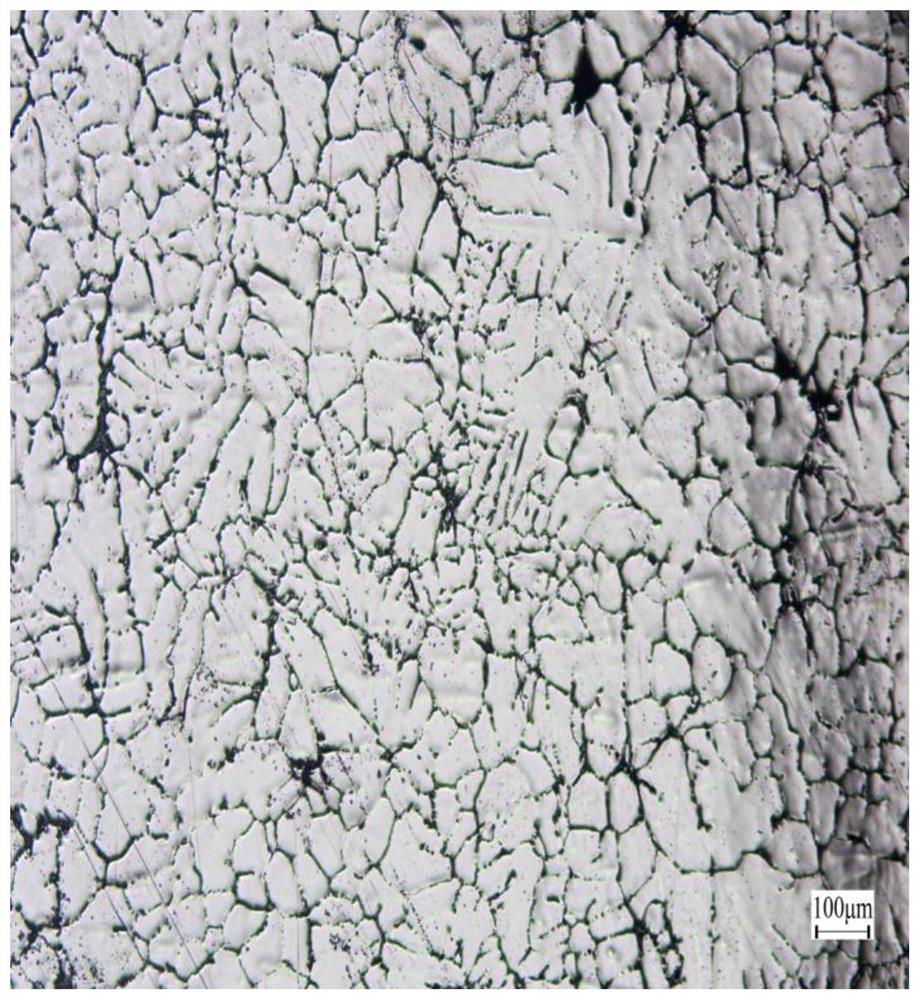

Embodiment 1

[0063] Example 1: Preparation of 6061 aluminum alloy semi-continuous cast rod containing 0.05% LaCe.

[0064] Melting: Put the aluminum ingot into the furnace and heat it to 720-750°C for melting;

[0065] Slagging: Sprinkle the slagging agent evenly into the furnace at a temperature of 725±25°C and stir it fully for 5-10 minutes. slag removal;

[0066] Alloying: copper, silicon, manganese, iron, titanium, magnesium, chromium, zinc, lanthanum and cerium mixed rare earth are added when the melt temperature is 730-750 °C, the above elements except magnesium and zinc are added in the form of pure metal, and the rest are in the form of master alloys Add in the same way, where the aluminum-lanthanum-cerium master alloy is added last, the weight of the lanthanum-cerium master alloy accounts for 0.05% of the total weight, the ratio of lanthanum-cerium rare earth is 1:1, and the order of other master alloys is not in particular order; after adding the alloy, stir for 10-15 minutes M...

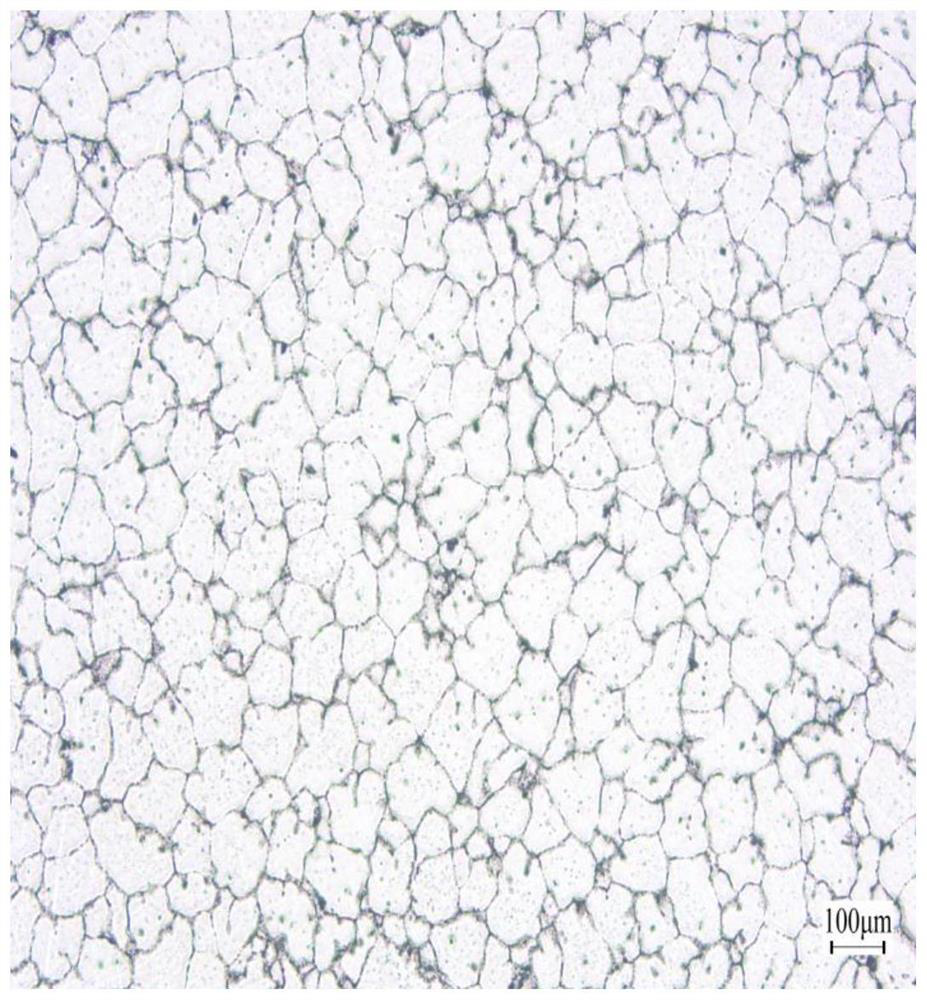

Embodiment 2

[0070] Example 2: Preparation of 6061 aluminum alloy semi-continuous cast rod containing 0.2% LaCe.

[0071] Melting: Put the aluminum ingot into the furnace and heat it to 720-750°C for melting;

[0072] Slagging: Sprinkle the slagging agent evenly into the furnace at a temperature of 725±25°C and stir it fully for 5-10 minutes. slag removal;

[0073] Alloying: Copper, silicon, manganese, iron, titanium, magnesium, chromium, lanthanum and cerium mixed rare earth are added when the melt temperature is 730-750°C. The above elements except magnesium and zinc are added in the form of pure metal, and the rest are added in the form of master alloy , wherein the aluminum-lanthanum-cerium master alloy is added last, the weight of the lanthanum-cerium master alloy accounts for 0.2% of the total weight, the ratio of the lanthanum-cerium rare earth is 1:1, and the order of adding other master alloys is not in any order; after adding the alloy, stir for 10 to 15 minutes to melt The ing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com