Leadfree SnZn-base alloy solder containing rare-earth elements

A technology of rare earth elements and lead-free solder, which is applied in metal processing equipment, welding/cutting media/materials, welding media, etc., can solve the problem of poor wettability and corrosion resistance of alloys, low bonding strength of brazed joints, and insufficient effect Remarkable and other problems, to achieve the effect of suitable melting point, excellent tissue stability and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

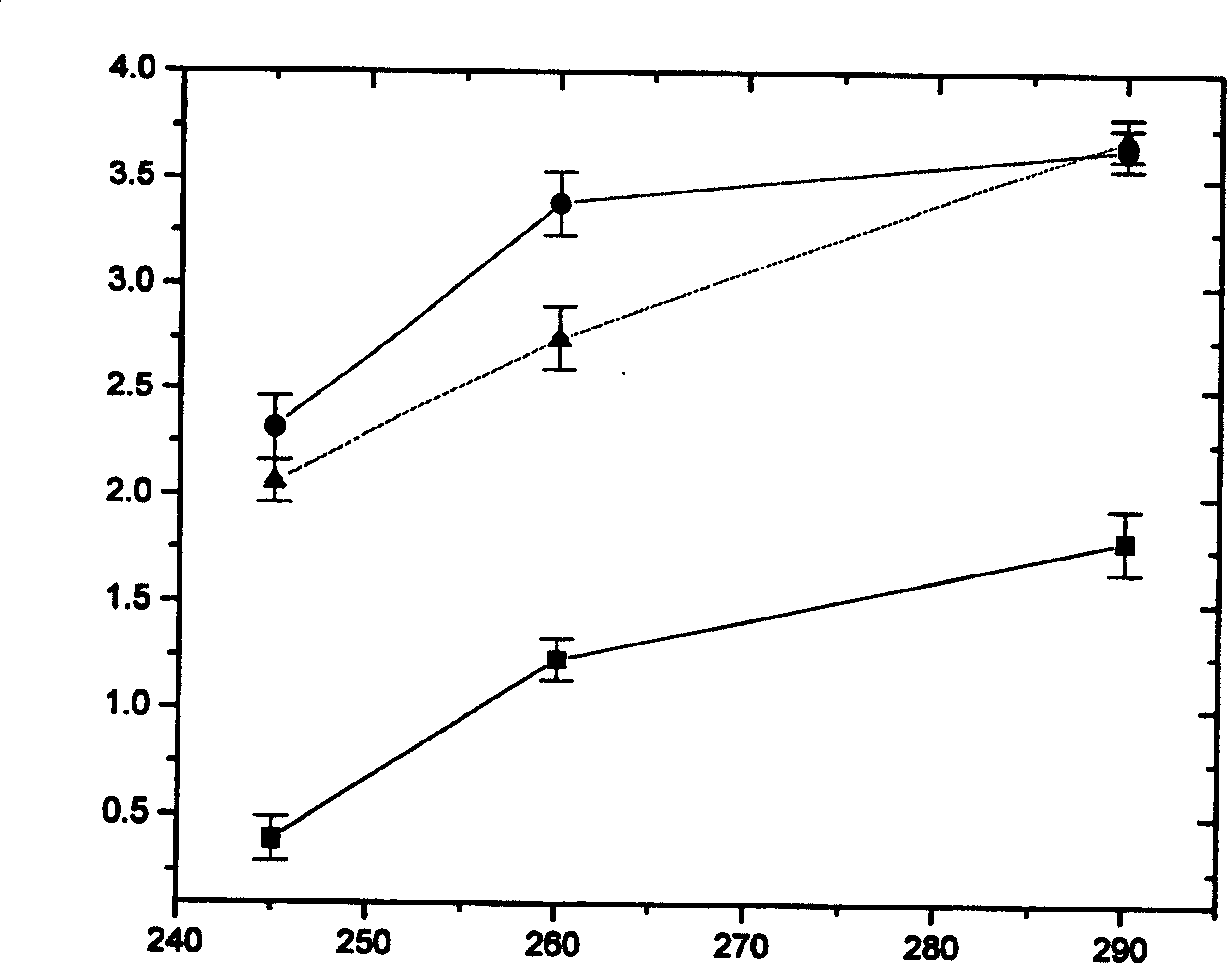

Image

Examples

Embodiment approach

[0023] The following chemical composition (%) is selected: (7-9) Zn; (0.05-0.15) RE; (0.5-3) Bi; (0.2-0.5) Al, and the balance is Sn. The above-mentioned raw materials prepared according to the composition are put into an industrial vacuum induction furnace for smelting, under normal pressure, the temperature is kept at 500°C for 4-6 hours, and the solder alloy can be obtained by pouring, and the brazing powder is prepared by spraying, and the brazing flux is added , the solder paste is obtained. Can be used for reflow soldering.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com