Heat-resistant anticorrosion metallic magnesium refining kettle and preparation method thereof

A metal magnesium, refining pot technology, applied in heat treatment equipment, heat treatment furnaces, manufacturing tools and other directions, can solve the problems of large thermal creep, poor corrosion resistance of refining pots, pot cracking, etc., to improve heat resistance and prevent Corrosion, excellent comprehensive mechanical properties, and the effect of reducing casting pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A method for preparing a metal magnesium refining pot, comprising the following steps:

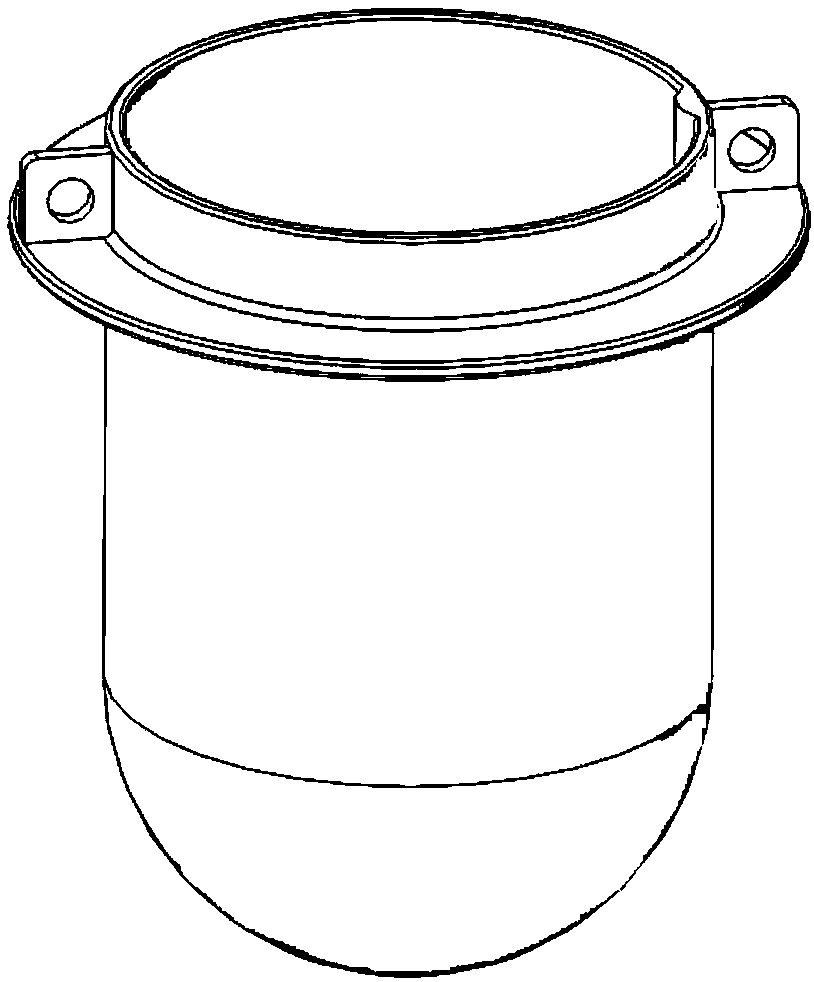

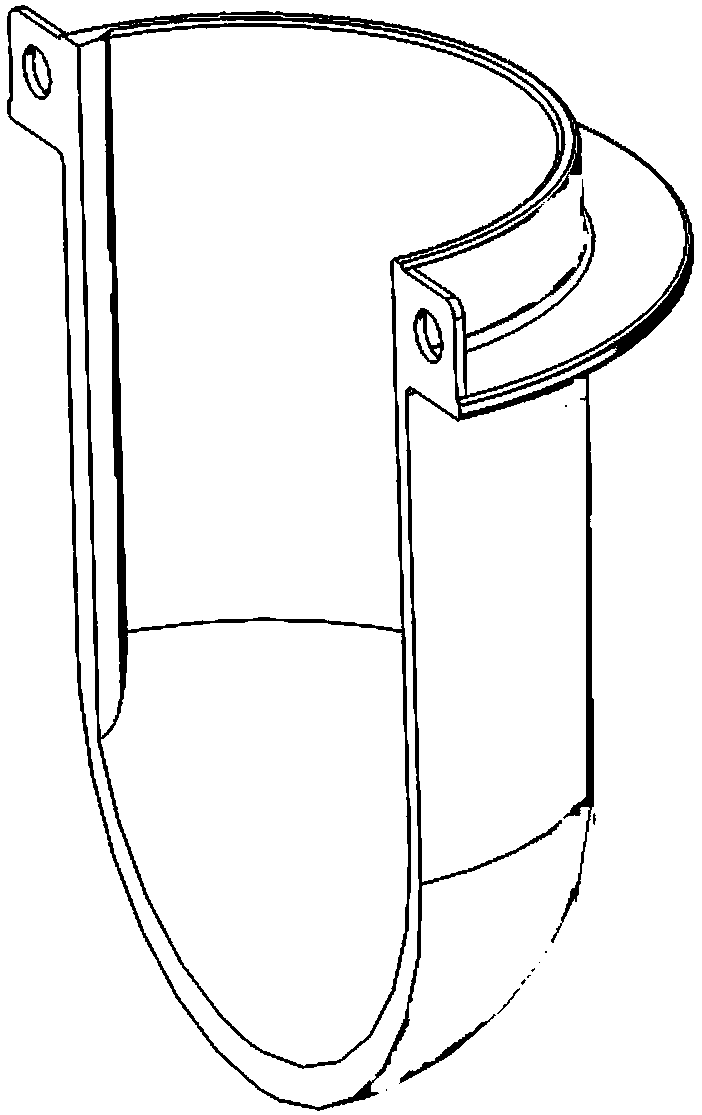

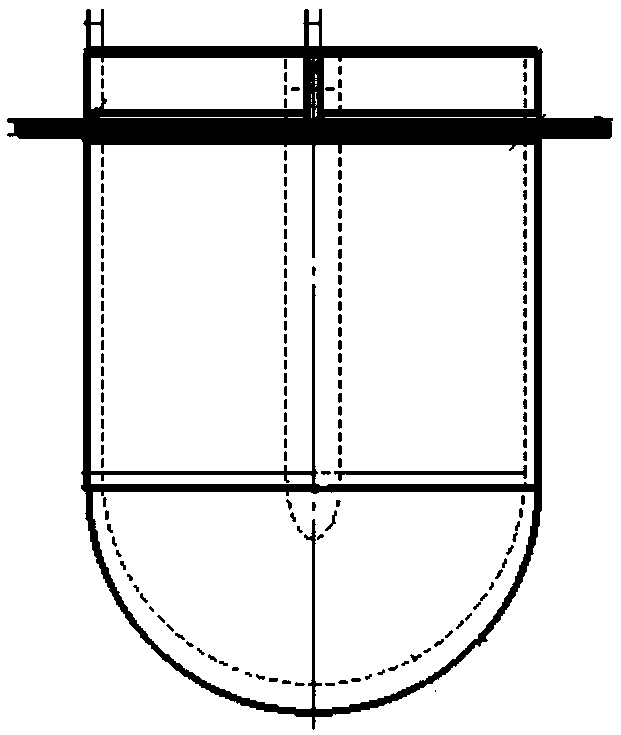

[0029] Step 1, according to the material matching and design drawings of the integrated casting refining pot (such as Figure 1 to Figure 5 shown), formulate the corresponding casting process; use the lost foam model to prepare by vacuuming; the feeding sequence of the melting furnace: heat-resistant steel → high ferrochrome → low ferrochrome → ferromanganese → ferrosilicon → ferromolybdenum → rare earth for smelting, During the smelting process, the protective gas nitrogen is introduced, and the pouring is performed after the smelting is completed; the pouring temperature is 1620±5°C, the pouring time is 30-50s, and the pouring method is pouring from the side wall riser of the refining pot;

[0030] Step 2: After cleaning the pouring body, put it into a heat treatment furnace for heating at a heating temperature of 1050-1100°C and keep it warm for 1.8-2.5 hours; then put it into an...

Embodiment 1

[0035] A heat-resistant and anti-corrosion metal magnesium refining pot. The mass percentage of the chemical composition of the metal magnesium refining pot is: 0.4%C, 16%Cr, 3%Mn, 1.6%Si, 0.1%Ni, 0.02%Mo, 0.6%N, 0.01% S, 0.01% P, 0.12% rare earth, the balance is Fe.

[0036] The above-mentioned refining pot preparation method adopts the lost foam vacuuming method, that is, the integrated refining pot is obtained by using the lost foam (expandable polystyrene resin beads) casting method.

[0037] A method for preparing a metal magnesium refining pot, comprising the following steps:

[0038] Step 1, according to the material matching and design drawings of the integrated casting refining pot (such as Figure 1 to Figure 5 shown), formulate the corresponding casting process; use the lost foam model to prepare by vacuuming; the feeding sequence of the melting furnace: heat-resistant steel → high ferrochrome → low ferrochrome → ferromanganese → ferrosilicon → ferromolybdenum → ra...

Embodiment 2

[0043] A heat-resistant and anti-corrosion metal magnesium refining pot. The mass percentage of the chemical composition of the metal magnesium refining pot is: 0.65%C, 21%Cr, 5%Mn, 2.0%Si, 0.2%Ni, 0.03%Mo, 1.2%N, 0.018% S, 0.018% P, 0.2% rare earth, the balance is Fe.

[0044] The above-mentioned refining pot preparation method adopts the lost foam vacuuming method, that is, the integrated refining pot is obtained by using the lost foam (expandable polystyrene resin beads) casting method.

[0045] A method for preparing a metal magnesium refining pot, comprising the following steps:

[0046] Step 1, according to the material matching and design drawings of the integrated casting refining pot (such as Figure 1 to Figure 5 shown), formulate the corresponding casting process; use the lost foam model to prepare by vacuuming; the feeding sequence of the melting furnace: heat-resistant steel → high ferrochrome → low ferrochrome → ferromanganese → ferrosilicon → ferromolybdenum → ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com