High-temperature-resistant and corrosion-resistant magnesium alloy and preparation process thereof

A preparation process and technology for magnesium alloys, applied in the field of alloy production and processing, can solve problems such as poor high temperature stability, application limitations, and poor corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

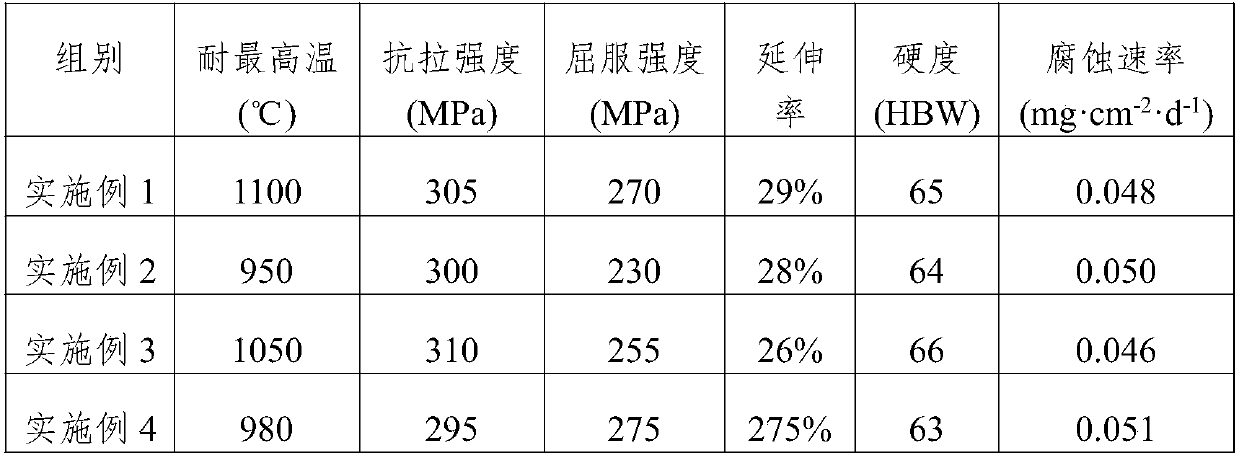

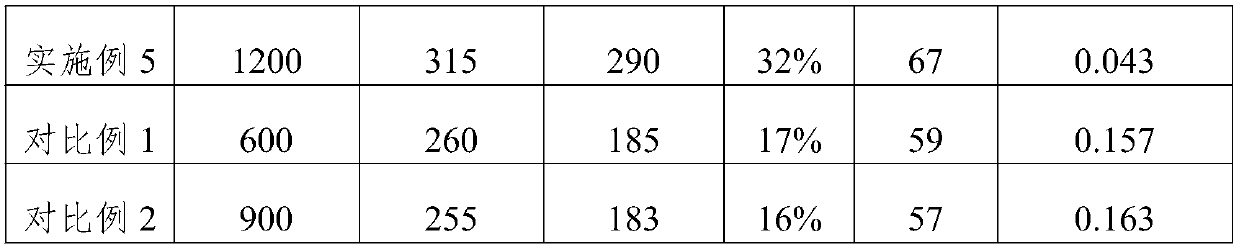

Examples

Embodiment 1

[0041] A high-temperature-resistant and corrosion-resistant magnesium alloy, the magnesium alloy is mainly composed of Mg, Mo, Zn, Zr, Sc, W and rare earth elements, and the mass percentages of each component are as follows: 4.5% Mo, 6.6% Zn, 2.3% Zr, 0.1% Sc, 0.1% W, 1.2% rare earth elements, the balance is Mg and unavoidable impurities; the unavoidable impurities are Ca, Al, etc., the total amount <0.05%.

[0042] Further, the rare earth elements are Ce, La, Ho, Yb, Sm, Tm, Gd, Y, Nd.

[0043] A preparation process for a high-temperature-resistant and corrosion-resistant magnesium alloy, comprising the following steps:

[0044] (1) Melting: Under the condition of continuous feeding of protective gas, first preheat the billet to 200°C, add industrial pure Mg to the preheated container and heat to 200°C to melt, raise the temperature to 700°C, add preheated Rare earth elements heated to 200°C, stirred evenly, and kept at 650°C for 7 hours;

[0045] (2) heat preservation trea...

Embodiment 2

[0051] A high-temperature-resistant and corrosion-resistant magnesium alloy, the magnesium alloy is mainly composed of Mg, Mo, Zn, Zr, Sc, W and rare earth elements, and the mass percentages of each component are as follows: 6.9% Mo, 8.8% Zn, 3.2% Zr, 0.6% Sc, 0.5% W, 1.8% rare earth elements, the balance is Mg and unavoidable impurities; the unavoidable impurities are Ca, Al, etc., the total amount of which is <0.05%.

[0052] Further, the rare earth elements are Ce, La, Sm, Tm, Gd, Dy, Pr, Y, Nd.

[0053] A preparation process for a high-temperature-resistant and corrosion-resistant magnesium alloy, comprising the following steps:

[0054] (1) Melting: Under the condition of continuous feeding of protective gas, first preheat the billet to 200°C, add industrial pure Mg to the preheated container and heat to 220°C to melt, raise the temperature to 750°C, add preheated Rare earth elements heated to 200°C, stirred evenly, and kept at 680°C for 5 hours;

[0055] (2) heat preserv...

Embodiment 3

[0061] A high-temperature-resistant and corrosion-resistant magnesium alloy, the magnesium alloy is mainly composed of Mg, Mo, Zn, Zr, Sc, W and rare earth elements, and the mass percentages of each component are as follows: 4.7% Mo, 6.9% Zn, 2.5% Zr, 0.2% Sc, 0.2% W, 1.3% rare earth elements, the balance is Mg and unavoidable impurities; the unavoidable impurities are Ca, Al, etc., the total amount of which is less than 0.05%.

[0062] Further, the rare earth elements are Ce, La, Eu, Yb, Sm, Tm, Gd, Dy, Y.

[0063] A preparation process for a high-temperature-resistant and corrosion-resistant magnesium alloy, comprising the following steps:

[0064] (1) Melting: Under the condition of continuous feeding of protective gas, first preheat the billet to 200°C, add industrial pure Mg to the preheated container and heat to 205°C to melt, raise the temperature to 710°C, add preheated Rare earth elements heated to 200°C, stirred evenly, and kept at 660°C for 6.5h;

[0065] (2) heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com