Four-shaft numerically controlled ellipsoidal and spherical hobbing cutter spade milling machine tool

An ellipsoidal and spherical technology, which is applied in the field of four-axis CNC ellipsoidal and spherical hob relief grinding machine tools, can solve the problems of hob normal tooth pitch out of tolerance, inability to move, and inability to correct

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

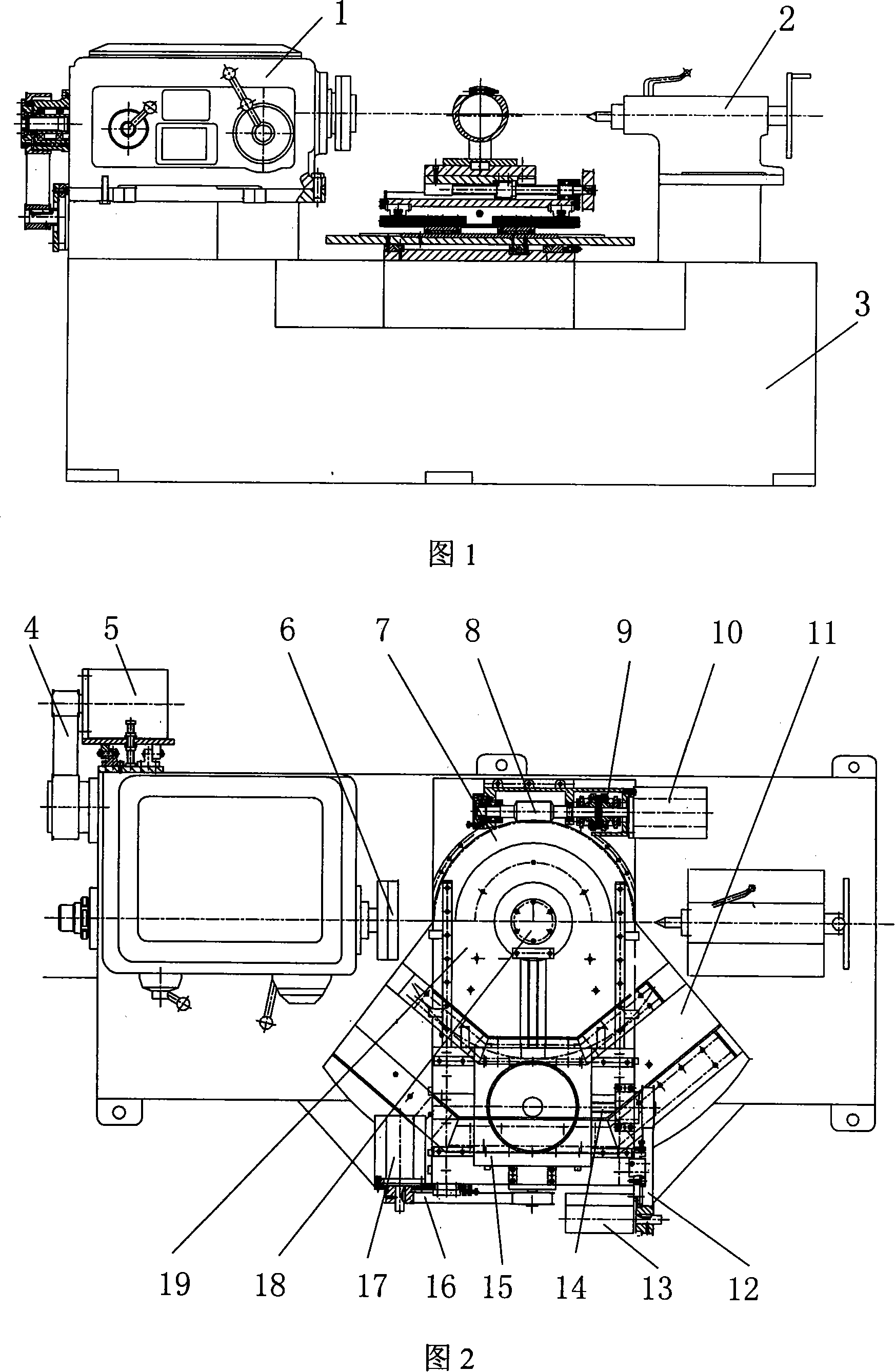

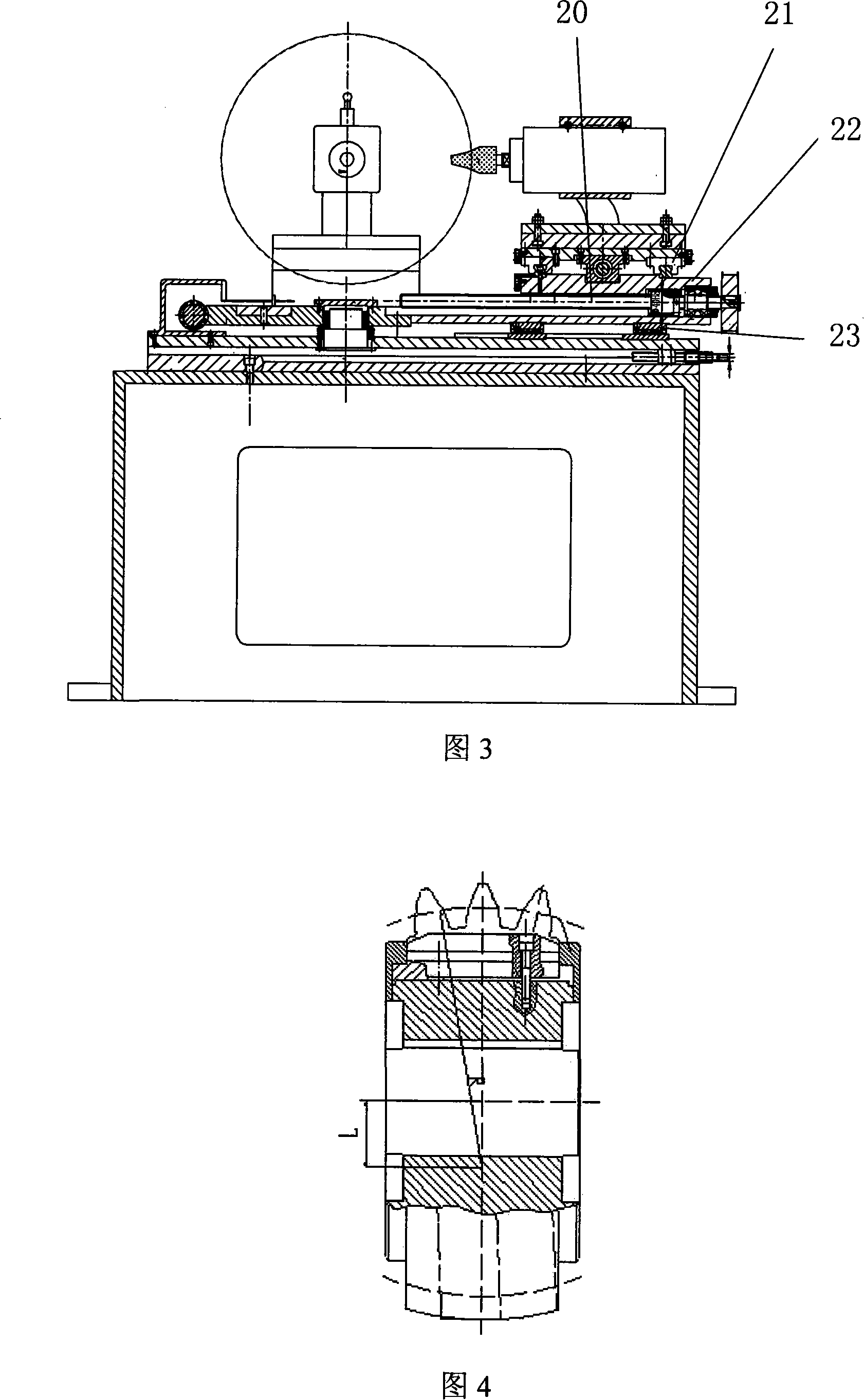

[0013] In order to solve the problem of manufacturing spherical and ellipsoidal hobs, the present invention has developed a processing device for ellipsoidal hobs-a four-axis numerically controlled ellipsoidal hob and a spherical hob grinding machine tool, as shown in Figs. 1, 2 and 3. It includes a headstock 1, a tailstock 2 and a bed 3. The bed 3 is equipped with a position-adjustable arc adjusting plate 11 and a rotating plate 19 that can rotate around a rotating shaft 18 fixed on the arc adjusting plate 11. The rotating plate 19 is successively installed with a radial feed tool post 22, a tangential feed tool post 15 and a tool from low to high; the rotating shaft 18 is perpendicular to the main shaft, and the rotating plate 19 and the arc adjusting plate 11 are rolled by an arc. The guide rail 23 is supported, and the radial feed tool holder 22 and the tangential feed tool holder 15 are respectively supported by the linear rolling guide 21. A worm gear 7 is installed on the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com