Construction method of traffic door opening in bridge road overline construction

A construction method and technology in construction, applied to roads, bridges, roads, etc., can solve problems such as unsteady placement, inconvenient operation of threading, long dismantling cycle, etc., and achieve the effects of material saving, convenient and quick separation, and time saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

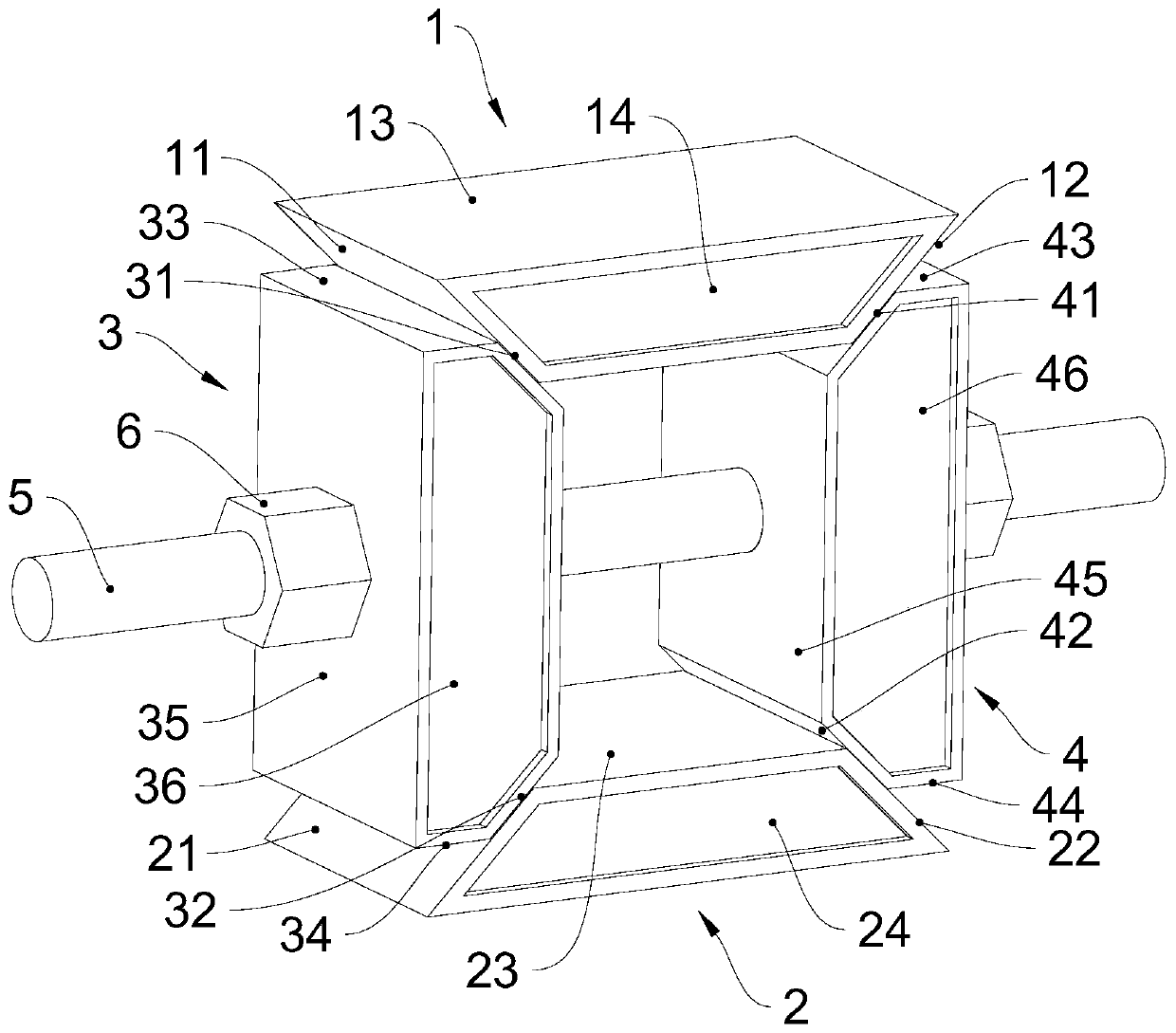

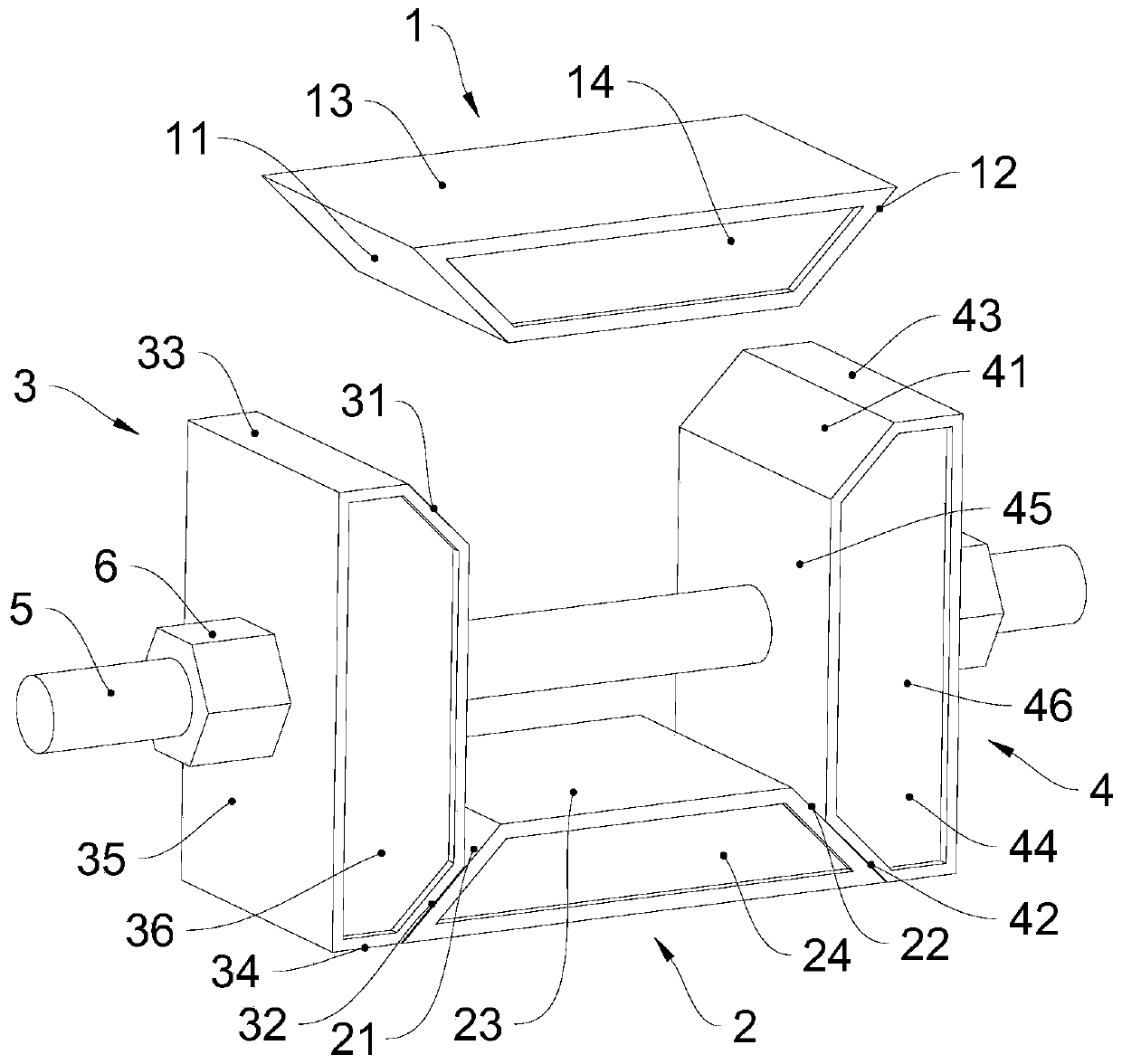

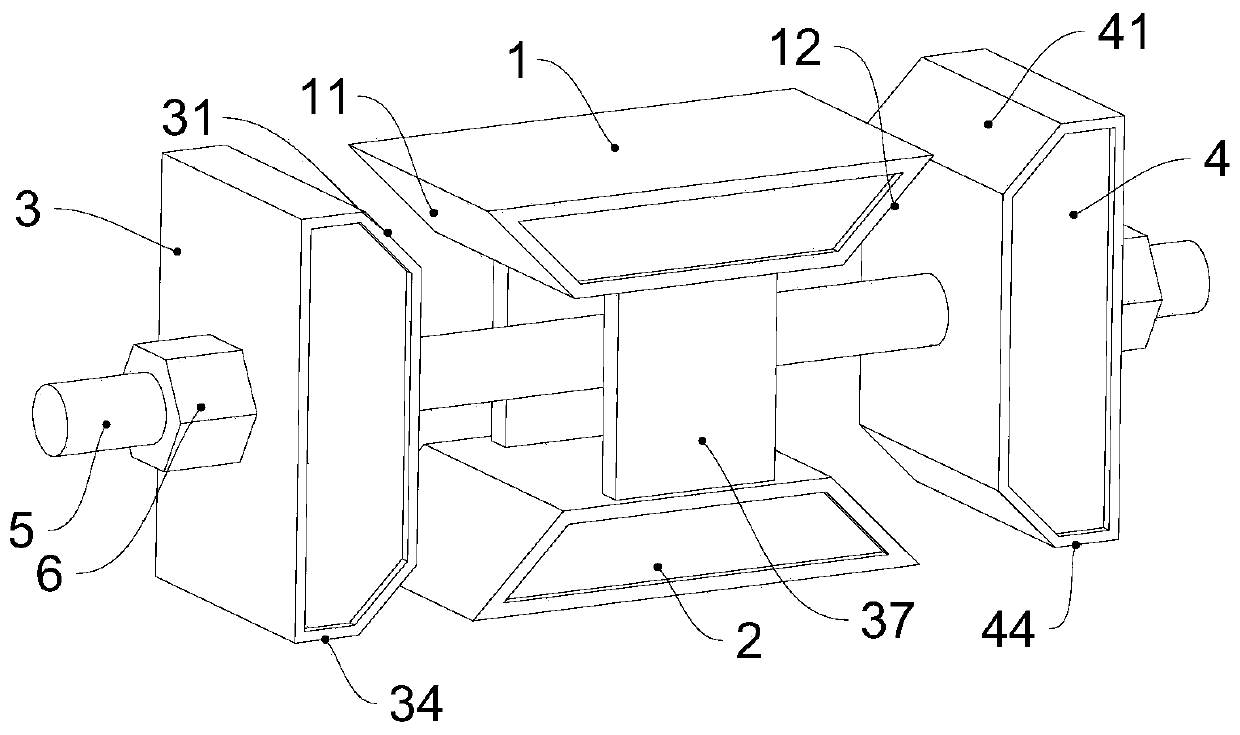

[0012] The first embodiment of the unloading device

[0013] see figure 1 and figure 2 , the unloading device of this embodiment includes an upper support 1, a lower support 2, a left slider 3, a right slider 4, a screw rod 5 and two nuts 6, the upper support 1 is located above the lower support 2, and the left The slide block 3 and the right slide block 4 are located on both sides of the lower support 2, the left slide block 3 and the right slide block 4 are provided with through holes, so that the screw rod 5 runs through the left slide block 3 and the right slide block 4, and the screw rod 5 The axial direction is parallel to the bottom wall of the lower support 2, and the nut 6 is screwed on the end of the screw rod 5, so that the left slider 3 and the right slider 4 are located between the two nuts 6, and the end faces of the nut 6 are respectively connected to the left slider. The side wall of the block 3 and the side wall of the right slider 4 are adjacent to each ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com