Lithium ion battery pack convergence board

A lithium battery pack and busbar technology, which is applied to battery pack components, circuits, electrical components, etc., can solve the problems of resource consumption, exhaust gas pollution, and high prices, and achieve lower production costs, reliable and stable welding, and strong strain resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

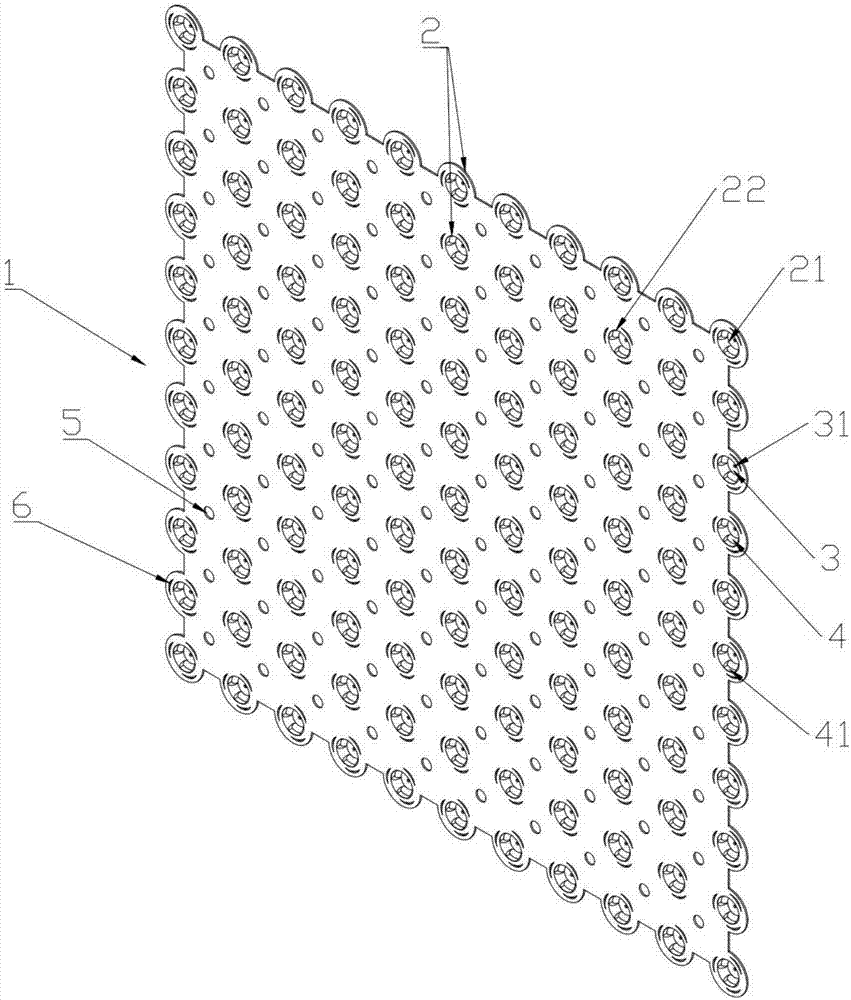

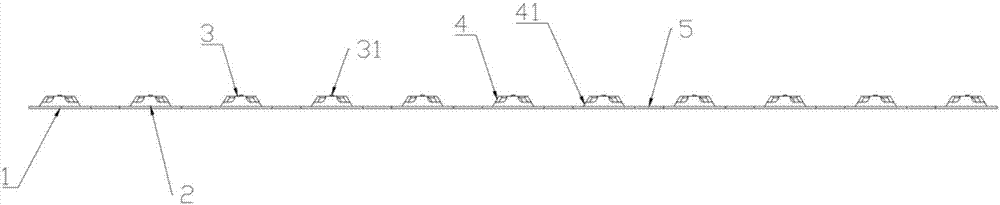

[0020] Such as Figure 1-Figure 2 As shown, a lithium battery pack busbar includes a busbar main body 1, a plurality of welding through holes 2 provided on the busbar main body 1, and a plurality of busbars 3; the busbars 3 and the welding through holes 2 are not on the same plane, and The bus bar 3 and the welding through holes 2 have the same number, shape, and axis; a number of connecting parts 4 are equidistantly arranged on the periphery of the bus bar 3, and the connecting parts 4 are connected with the welding through holes 2.

[0021] Such as Figure 1-Figure 2 As shown, a lithium battery pack busbar includes a busbar main body 1, a plurality of welding through holes 2 provided on the busbar main body 1, and a plurality of busbars 3; the busbars 3 and the welding through holes 2 are not on the same plane, and The number, shape and axis of the bus bar 3 and the welding through holes 2 are the same, and are not limited. The shape of the welding through holes 2 and the bus ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com