Gear forming device

A technology of forming device and gear, applied in the direction of gear tooth manufacturing device, belt/chain/gear, gear tooth, etc., can solve the problem of inability to stably cool the hob, and achieve the effect of good cooling effect, quality improvement, and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

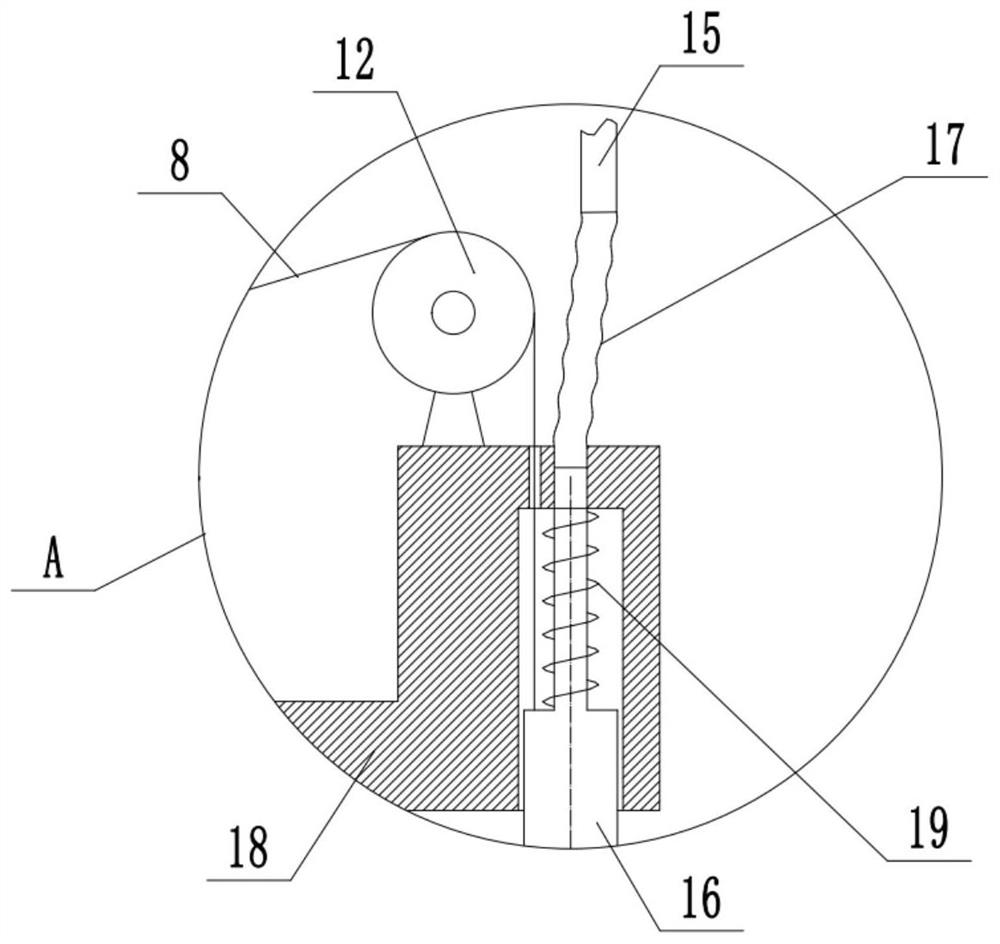

[0047] The difference between embodiment two and embodiment one is: as Figure 4 As shown, a second nozzle 21 is integrally formed near the bottom end of the first nozzle 16, and the second nozzle 21 faces the blank 5. When the cooling pipe 15 supplies cooling oil to the first nozzle 16, part of the cooling oil will flow from the second The nozzle 21 sprays towards the blank 5, so that the blank 5 is cooled and lubricated during processing, and at the same time, the cooling oil sprayed from the second nozzle 21 is used to clean the blank 5, so as to avoid the debris generated by cutting from adhering to the blank 5 outer wall and cause interference to hob 4 cutting blank 5.

[0048] Such as Figure 5 As shown, the first nozzle 16 and the second nozzle 21 are uniformly formed with a plurality of splitters 22, and the adjacent splitters 22 are fixedly connected with the flow guides 23 perpendicular to the flow splitters 22, and the adjacent flow guides 23 There is an included ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com