Method for preparing crisp carrot slices, the crisp carrot slices and full nutrition carrot powder

A technology of carrot slices and carrots, applied in food drying, climate change adaptation, food science and other directions, can solve the problems of low dehydration efficiency, high drying energy consumption, high oil content, shorten drying time, reduce energy consumption, and reduce operation. The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

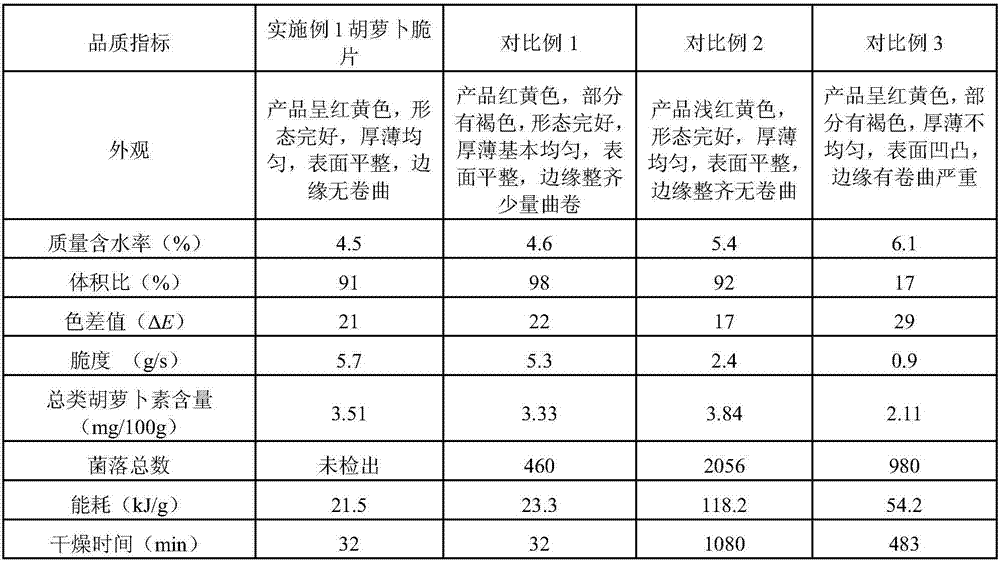

Embodiment 1

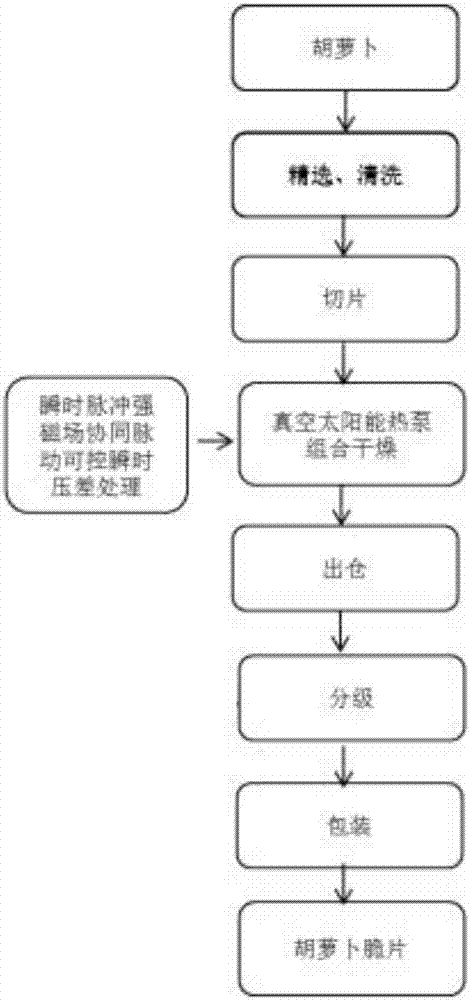

[0053] (1) Selection, washing and slicing:

[0054] 1a) Select carrots with a diameter of 25-60 mm, remove corrupted, damaged, deformed and diseased carrots, and clean them;

[0055] 1b) Slicing the carrot after cleaning in step 1a) by mechanical means, with a slice thickness of 6 mm;

[0056] (2) Drying with solar energy combined with vacuum heat pump: The conditions for drying carrot slices with solar energy combined with vacuum heat pump are: vacuum pressure 3kPa, drying temperature 70°C.

[0057] During the period, the auxiliary instantaneous pulsed strong magnetic field cooperates with the pulsating controllable instantaneous pressure difference treatment: Among them, during the pulsation controllable instantaneous pressure difference treatment process, the pressure of the treatment chamber is increased to 0.5MPa, the temperature reaches 150°C, the stagnation time is 20s, and the pressure after pressure relief is 3kPa; the cycle interval of pulsating and controllable ins...

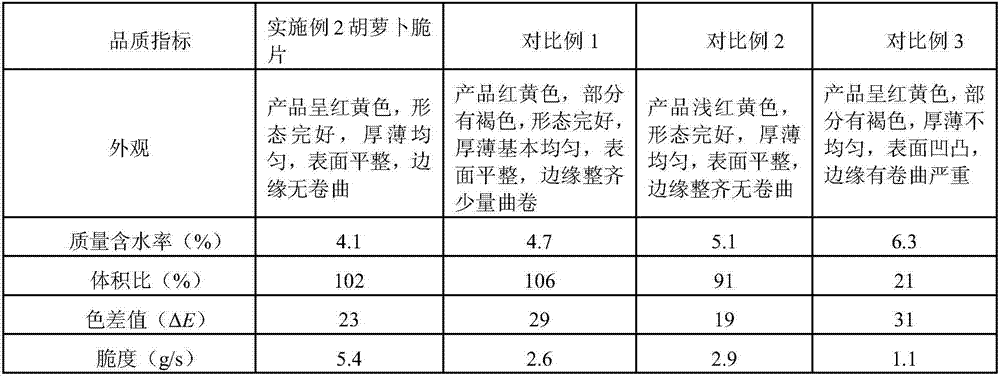

Embodiment 2

[0076] The production method of carrot chips is substantially the same as the method described in Example 1, except that:

[0077] The slice thickness of the carrot slices in the step (1) is 7mm;

[0078] Step (2) During the drying process of solar combined vacuum heat pump, the drying temperature is 45°C and the vacuum degree is 10kPa;

[0079] During the period, in step (2), the auxiliary instantaneous pulse strong magnetic field coordinated with the pulsating controllable instantaneous pressure difference processing parameters are: the instantaneous pressure difference processing temperature is 110°C, the pressure is 0.15MPa, the stagnation time is 2min, and the pressure chamber pressure is 10kPa after pressure release. During the period, the pressure difference flash operation was performed twice; during the pulsating and controllable instantaneous pressure difference treatment process, the intensity of the instantaneous pulsed strong magnetic field loaded on the treatment c...

Embodiment 3

[0092] The production method of carrot chips, as described in Example 1, the difference is:

[0093] The slice thickness of the carrot slices in the step (1) is 4mm;

[0094] Step (2) During the drying process of solar energy combined with vacuum heat pump, the drying temperature is 60°C, and the vacuum degree is 5kPa; the instantaneous pressure difference treatment described in step (2) is after the sample is placed in the processing chamber, and then dried with solar energy combined with vacuum heat pump for 2 minutes , carry out differential pressure flash evaporation, the steam temperature is 140°C, the pressure is 0.35MPa, and the treatment time is 40s; after that, the pressure is released to 5kPa, and the vacuum combined with solar energy is used for drying, with an interval of 2min, and the differential pressure flash evaporation operation is repeated 6 times; finally, the solar energy is used Combined with vacuum heat pump drying, the temperature is 70°C, and the vacuu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com