Polyurethane sound insulation coating and production process thereof

A technology of sound insulation coating and production process, applied in polyurea/polyurethane coatings, anti-corrosion coatings, fire-retardant coatings, etc., can solve the problems of insufficient polyurethane strength, high production cost, unstable damping performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

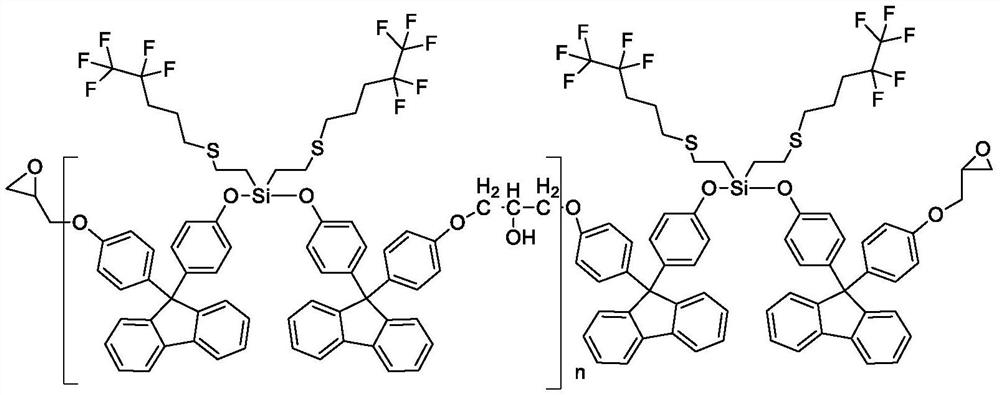

[0036] This embodiment provides a modified hollow glass microsphere, which is made by the following steps:

[0037] Step A1. Soak 15 g of hollow glass microspheres in 200 mL of sodium hydroxide solution with a mass fraction of 5%, stir and soak for 6 hours at a rotating speed of 200 r / min, then stop stirring and soak for 24 hours, then wash with distilled water for 3 times, filter with suction, and The cake was washed until the washing solution was neutral, and then dried in an oven at 80°C to constant weight to obtain pretreated glass beads;

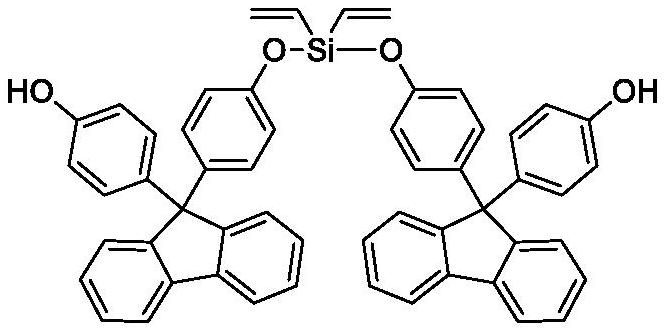

[0038] Step A2. Add 0.05mol 9,9'-bis(4-hydroxyphenyl)fluorene to 190mL 1,4-dioxane, under nitrogen protection, stir and heat up to 60°C, dropwise add 0.025mol divinyldi Chlorosilane, control the dropping rate at 1 drop / second, after the dropwise addition, stir and react for 4 hours, after the reaction, remove 1,4-dioxane by rotary evaporation to obtain the intermediate product 1;

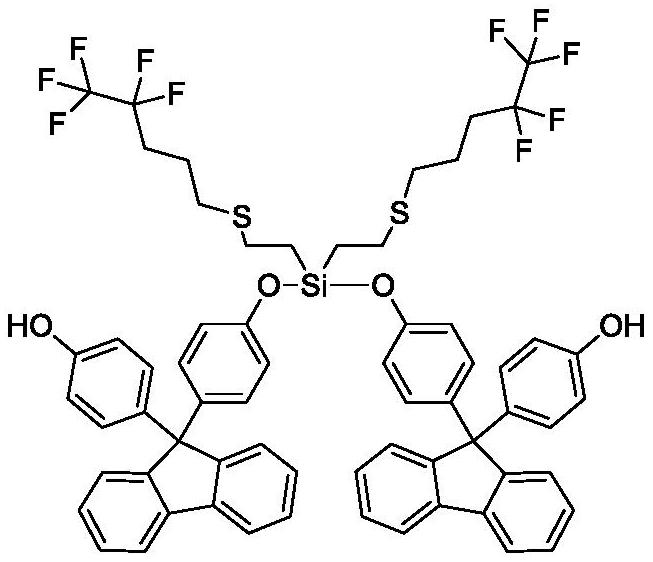

[0039] Step A3: Add 0.05 mol of pentafluoropentanethio...

Embodiment 2

[0043] This embodiment provides a modified hollow glass microsphere, which is made by the following steps:

[0044] Step A1. Soak 17g of hollow glass microspheres in 220mL of sodium hydroxide solution with a mass fraction of 8%, stir and soak for 6h at a rotating speed of 250r / min, then stop stirring and soak for 24h, then wash with distilled water for 4 times, suction filter, filter The cake was washed until the washing solution was neutral, and then dried in an oven at 80°C to constant weight to obtain pretreated glass beads;

[0045] Step A2. Add 0.05mol 9,9'-bis(4-hydroxyphenyl)fluorene to 220mL 1,4-dioxane, under the protection of nitrogen, stir and heat up to 60°C, dropwise add 0.025mol divinyldi Chlorosilane, control the dropping rate to 1 drop / second, after the dropwise addition, stir and react for 5h, after the reaction, remove 1,4-dioxane by rotary evaporation to obtain the intermediate product 1;

[0046] Step A3: Add 0.05 mol of pentafluoropentanethiol and 70 mL o...

Embodiment 3

[0050] This embodiment provides a modified hollow glass microsphere, which is made by the following steps:

[0051] Step A1, soak 18g of hollow glass microspheres in 250mL of sodium hydroxide solution with a mass fraction of 10%, stir and soak for 6h at a rotating speed of 300r / min, then stop stirring and soak for 24h, then wash with distilled water 5 times, suction filter, filter The cake was washed until the washing solution was neutral, and then dried in an oven at 80°C to constant weight to obtain pretreated glass beads;

[0052] Step A2. Add 0.05mol 9,9'-bis(4-hydroxyphenyl)fluorene to 250mL 1,4-dioxane, under nitrogen protection, stir and heat up to 60°C, dropwise add 0.025mol divinyl di Chlorosilane, control the dropping rate to 2 drops / second, after the dropping, stir the reaction for 6h, after the reaction, remove the 1,4-dioxane by rotary evaporation to obtain the intermediate product 1;

[0053] Step A3: Add 0.05 mol of pentafluoropentanethiol and 80 mL of carbon t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com