Sound insulation composite aluminum plate for curtain wall and preparation method thereof

A composite aluminum and aluminum plate technology, applied in the field of composite panels, can solve the problems of poor sound insulation and high cost of aluminum-plastic composite panels, and achieve the effects of improving sound insulation and noise reduction, reducing density, and preventing the entry of peripheral debris

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

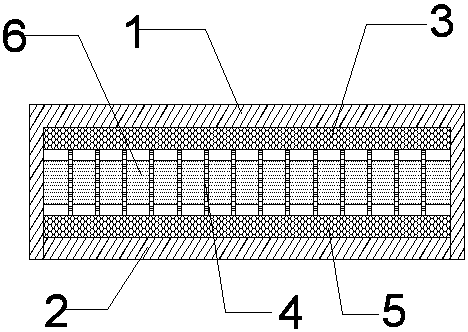

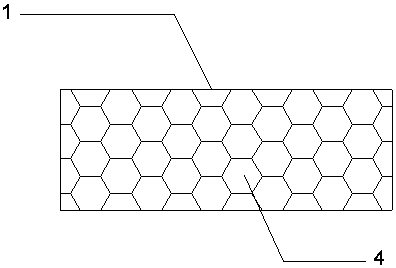

Image

Examples

Embodiment 1

[0027] (1) Prepare the components of the non-metallic composite layer by weight ratio. The non-metallic composite layer is composed of the following components by weight: 30 parts of polyethylene, 45 parts of straw powder, 5 parts of lipid plasticizer, naphthenic oil 1 part, 2 parts of stearic acid, 1 part of mica powder, put into the high mixer and mix for 20 minutes, the temperature is set at 70°C, after the mixing is completed, put into the preheated internal mixer, the internal mixing time is 10 minutes, the temperature is 130°C, and finally the twin-screw extruder is used to extrude, heat-cut, granulate and shape, and the temperature is set to 120°C;

[0028] (2) Take the upper aluminum plate and pass it through a bending machine to bend it into a groove structure with an open bottom, and weld the surrounding joints;

[0029] (3) Take the non-metal composite layer prepared in (1), preheat to 60°C, coat one side with polymer adhesive film, and then attach the side coated w...

Embodiment 2

[0034] (1) Prepare the components of the non-metallic composite layer by weight ratio. The non-metallic composite layer is composed of the following components by weight: 32 parts of polyethylene, 48 parts of straw powder, 6 parts of lipid plasticizer, naphthenic oil 0.5 parts, 1 part of stearic acid, 1 part of mica powder, first put into the high mixer and mix for 30 minutes, the temperature is set at 80°C, after the mixing is completed, put into the preheated internal mixer, the internal mixing time is 10 minutes, the temperature is 140°C, and finally the twin-screw extruder is used to extrude, heat-cut, granulate and shape, and the temperature is set to 130°C;

[0035] (2) Take the upper aluminum plate and pass it through a bending machine to bend it into a groove structure with an open bottom, and weld the surrounding joints;

[0036] (3) Take the non-metal composite layer prepared in (1), preheat to 65°C, coat one side with polymer adhesive film, and then attach the side ...

Embodiment 3

[0041] (1) Prepare the components of the non-metallic composite layer by weight ratio. The non-metallic composite layer is composed of the following components by weight: 35 parts of polyethylene, 50 parts of straw powder, 7 parts of lipid plasticizer, naphthenic oil 1 part, 1 part of stearic acid, 2 parts of mica powder, first put into the high-speed mixer and mix for 4 minutes, the temperature is set at 70 ° C, after the mixing is completed, put into the preheated internal mixer, the internal mixing time is 15 minutes, the temperature is 135°C, and finally the twin-screw extruder is used to extrude, heat-cut, granulate and shape, and the temperature is set to 140°C;

[0042] (2) Take the upper aluminum plate and pass it through a bending machine to bend it into a groove structure with an open bottom, and weld the surrounding joints;

[0043] (3) Take the non-metal composite layer prepared in (1), preheat to 65°C, coat one side with polymer adhesive film, and then attach the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com