Run-through channel for track passenger trains

A rail passenger car and passageway technology, which is applied to the railway car body, railway car body parts, transportation and packaging, etc., can solve the problems that cannot meet the performance requirements of high-speed rail passenger cars, and achieve excellent adaptability and reset function, high durability Aging resistance, the effect of meeting performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will now be further described with reference to the accompanying drawings. These drawings are all simplified schematic diagrams only to illustrate the basic structure of the present invention in a schematic way, so they only show the structure related to the present invention

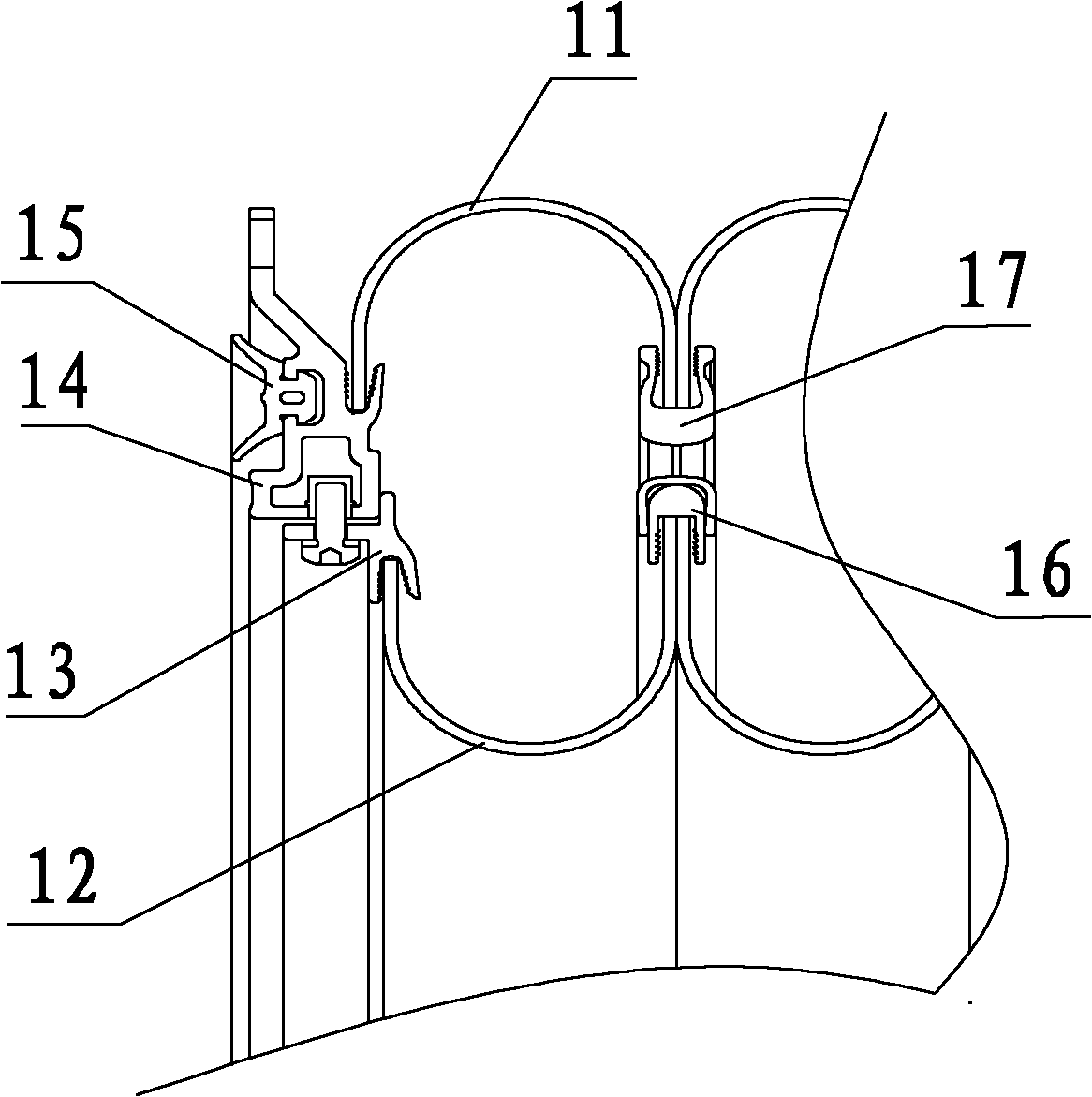

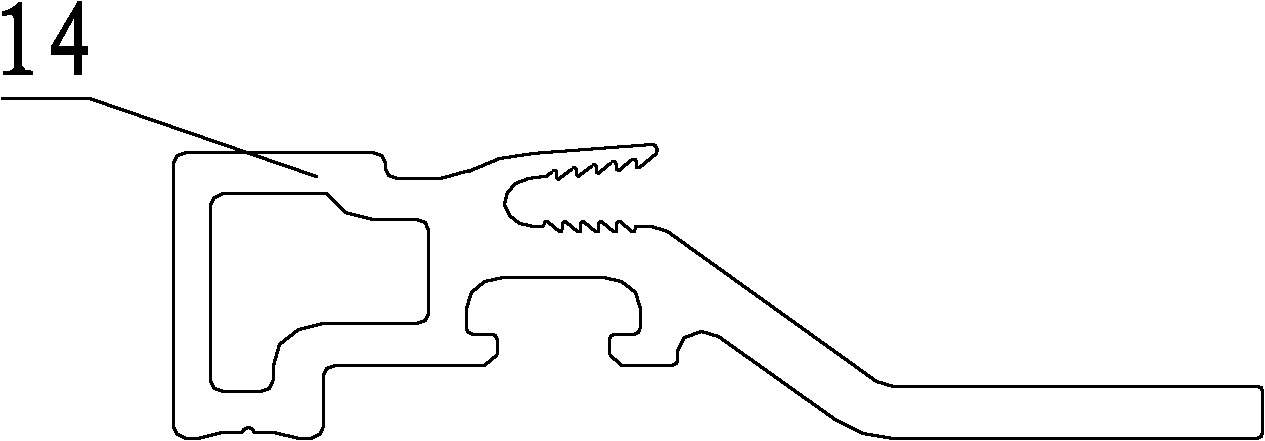

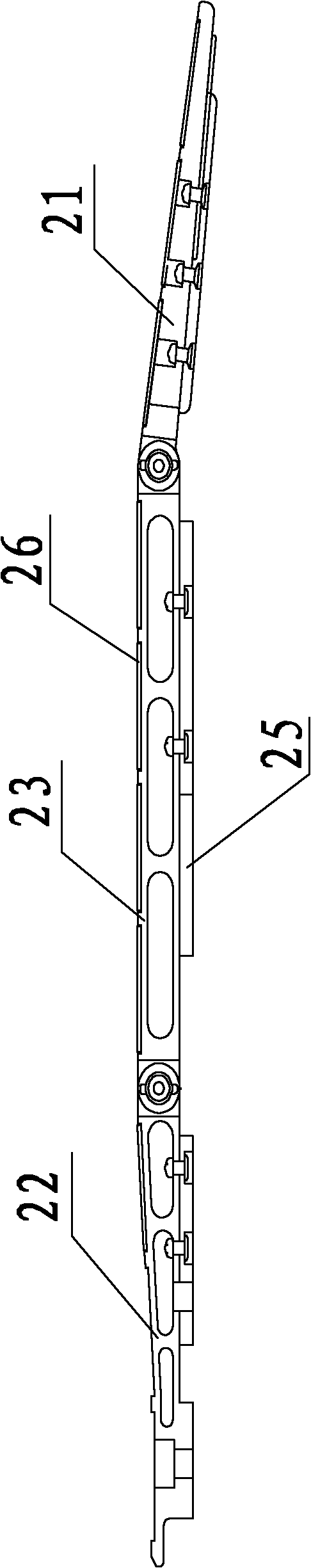

[0017] like figure 1 As shown in the figure, a through passage for rail passenger cars has a bellows main body assembly, a cross plate assembly, a pedal assembly, and a reset leaf spring assembly. The inner foldable body 12 of the inner arch, the end of the inner foldable body 12 is connected to the aluminum frame 13 with cloth, the outer folded body 11 is connected with the connecting frame 14 of the end wall, and the aluminum frame 13 with the cloth is fixedly connected with the connecting frame 14 of the end wall, The end wall connecting frame 14 is embedded with a rubber sealing strip 15 .

[0018] The inner foldable shed body 12 is formed by connecting 12 double-layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com