Rubber aggregate concrete

A rubber aggregate and concrete technology, applied in the field of concrete, can solve the problems of easily weakening the positive impact of rubber flexibility, difference in recovery rate, and difficulty in realization, and achieves the effect of promoting recycling, improving strength, and solving pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1: According to 450 parts of cement, 180 parts of water, 109 parts of fly ash, 1078 parts of gravel, 417 parts of sand, 80 parts of rubber aggregate, 2.18 parts of polycarboxylate superplasticizer and organosiloxane The counterweight of 0.27 parts of the foaming agent is prepared and the ingredients are prepared. Here, the water-cement ratio (i.e. the ratio of water to cement weight) is 0.4. Before mixing, the rubber aggregate is modified with absolute ethanol. The modification steps are: (1) Soak the rubber aggregate in absolute ethanol for 23 hours and then filter, (2) Clean the surface of the soaked rubber aggregate particles with tap water, (3) Put the cleaned rubber aggregate at a temperature of 60°C Dry and set aside. Put the dried rubber aggregate and other ingredients into the mixing device, and then mix and form according to the method specified in GB / T 50080-2002 "Standards for Experimental Methods of Performance of Ordinary Concrete Mixtures".

Embodiment 2

[0014] Embodiment 2: According to 400 parts of cement, 180 parts of water, 109 parts of fly ash, 1078 parts of gravel, 417 parts of sand, 80 parts of rubber aggregate, 2.18 parts of polycarboxylate superplasticizer and organosiloxane The counterweight of 0.27 parts of the foaming agent is prepared and the ingredients are prepared. The water-cement ratio here is 0.45. Before mixing, the rubber aggregates are modified with absolute ethanol. The modification steps are: (1) put the rubber aggregates in an After soaking in water ethanol for 24 hours, filter, (2) wash the surface of the soaked rubber aggregate particles with tap water, (3) dry the cleaned rubber aggregate at a temperature of 65° C. for subsequent use. Put the dried rubber aggregate and other ingredients into the mixing device, and then mix and form according to the method specified in GB / T 50080-2002 "Standards for Experimental Methods of Performance of Ordinary Concrete Mixtures".

Embodiment 3

[0015] Embodiment 3: According to 360 parts of cement, 180 parts of water, 109 parts of fly ash, 1078 parts of gravel, 417 parts of sand, 80 parts of rubber aggregate, 2.18 parts of polycarboxylate superplasticizer and organosiloxane The counterweight of 0.27 parts of the foaming agent is prepared and the ingredients are prepared. Here, the water-cement ratio is 0.5. Before mixing, the rubber aggregates are modified with absolute ethanol. The modification steps are: (1) put the rubber aggregates in an After soaking in water ethanol for 25 hours, filter, (2) wash the surface of the soaked rubber aggregate particles with tap water, (3) dry the cleaned rubber aggregate at a temperature of 70° C. for subsequent use. Put the dried rubber aggregate and other ingredients into the mixing device, and then mix and form according to the method specified in GB / T 50080-2002 "Standards for Experimental Methods of Performance of Ordinary Concrete Mixtures".

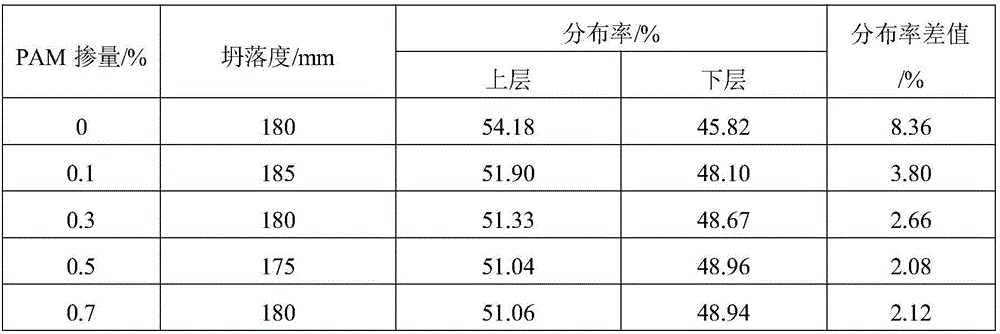

[0016] Further, the above-mentio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com