Injection-molded type TPO (thermoplastic polyolefin) compound for sound-insulating pads for automobiles as well as preparation method of compound

An injection molding and compound technology, applied in the field of polymer materials and their molding and processing, can solve the problems of poor fluidity and difficulty in injection molding, and achieve the effects of improving mold release, smooth mold release, and good moldability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

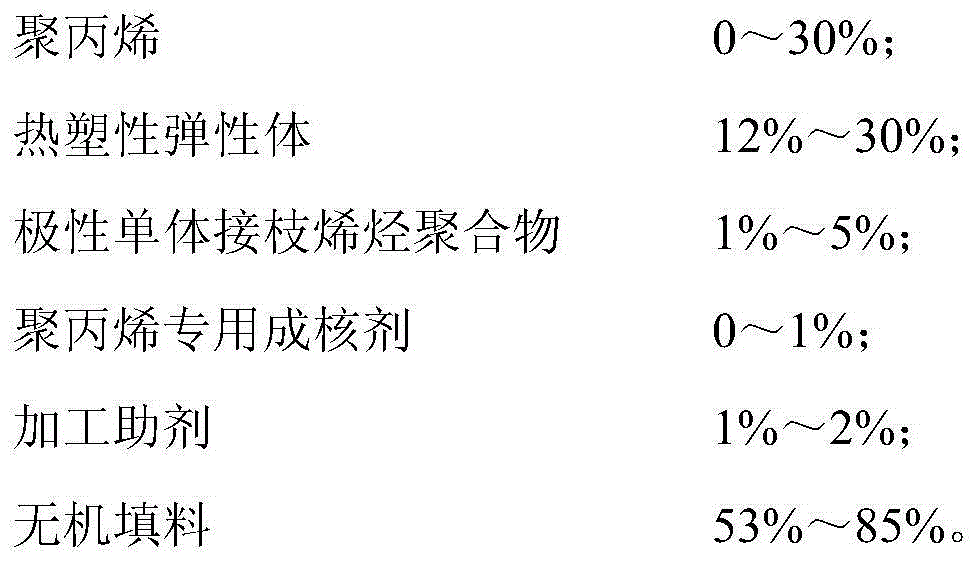

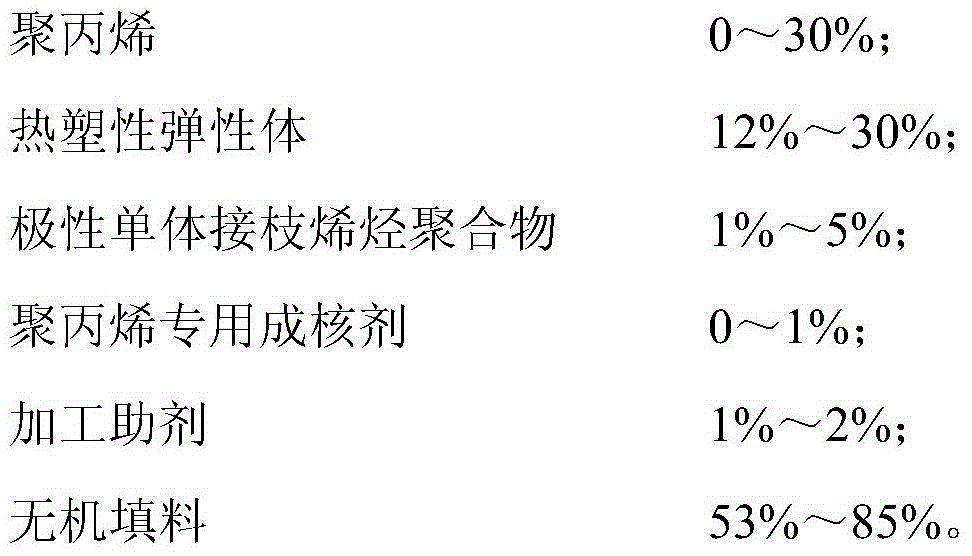

Method used

Image

Examples

Embodiment 1

[0020] 30 kg of polypropylene PP T30S, 30 kg of thermoplastic elastomer styrene-butadiene rubber YH503, 5 kg of linear low-density polyethylene LLDPE grafted with maleic anhydride graft Bondyram 4108, 0.4 kg of phenolic antioxidant 1010, 0.4 kg of sub Phosphate ester antioxidant 168, 1.2 kg of processing aid EBS, melted, mixed and dispersed in a twin-screw extruder with an aspect ratio of 40:1, 53 kg of barium sulfate was fed into the twin-screw extruder from the side through a weight-loss metering scale Extruder, the temperature of each section of the extruder is set at 190-225 ° C to extrude and granulate, and finally obtain the product.

[0021] Test its performance according to the corresponding standards, the list is as follows:

[0022] Table 1

[0023] performance

[0024] elongation at break

Embodiment 2

[0026] 7 kg of polypropylene PP Z30S, 15 kg of thermoplastic polyurethane elastomer 1185A, 2 kg of HDPE (high density polyethylene) grafted with maleic anhydride graft Bondyram 5101, 0.2 kg of phenolic antioxidant 1010, 0.2 kg of phosphite Antioxidant 168, 0.6 kg of processing aid EBS were melted, mixed and dispersed in a twin-screw extruder with a length-to-diameter ratio of 40:1, and 75 kg of 3000-mesh talcum powder was fed into the twin-screw extruder from the side through a weight-loss weighing scale Machine, the temperature of each section of the extruder is set at 190-225 ° C, extruded and granulated, and finally the product is obtained.

[0027] Test its performance according to the corresponding standards, the list is as follows:

[0028] Table 2

[0029] performance

Embodiment 3

[0031] 12 kg of polyolefin POE thermoplastic elastomer DF610, 1 kg of ethylene-α-octene copolymer maleic anhydride graft 493D, 1 kg of phosphate polypropylene special nucleating agent HPN-20E, 0.3 kg of phenolic antioxidant Agent 1010, 0.2 kg of phosphite antioxidant 627A, 0.5 kg of processing aid calcium stearate are melt-mixed and dispersed in a twin-screw extruder with a length-to-diameter ratio of 40:1, and 75 kg of barium sulfate is passed through a weight loss weighing scale Feed from the side into the twin-screw extruder, set the temperature of each section of the extruder at 190-225°C, extrude and granulate, and finally get the product.

[0032] Test its performance according to the corresponding standards, the list is as follows:

[0033] table 3

[0034] performance

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com