Magnesium oxysulfate cement foamed bricks and preparation method therefor

A technology of magnesium oxysulfate cement and foam bricks, which is applied in the field of construction products, can solve the problems of high energy consumption, inability to solve bulk density and strength, and failure to achieve low bulk density and high strength foaming, and achieve low density and good fire prevention effect , the effect of good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] The present invention also relates to the preparation method of this magnesium oxysulfate cement foam brick, comprising the following steps:

[0067] Weigh the raw materials in proportion, mix and stir magnesium sulfate, magnesium oxide, additives and water, add fillers and continue stirring to obtain cement slurry, pour hydrogen peroxide into the cement slurry and stir, pour into the mold, let stand, and naturally maintain for 15 minutes. Demoulding, cutting and curing for 3 to 7 days to obtain magnesium oxysulfide foamed bricks.

[0068] Specifically: mix magnesium sulfate, magnesium oxide, additives and water and stir for 5-10 minutes; quickly pour hydrogen peroxide into the slurry at a stirring speed of 300-500 rpm. Stirring time 20s ~ 60s.

Embodiment 1

[0076] In this embodiment, fly ash is used as lightweight aggregate, and the proportioning ratio of each raw material is shown in Table 1-1 and 1-2:

[0077] Table 1-1: Raw material ratio

[0078] raw material

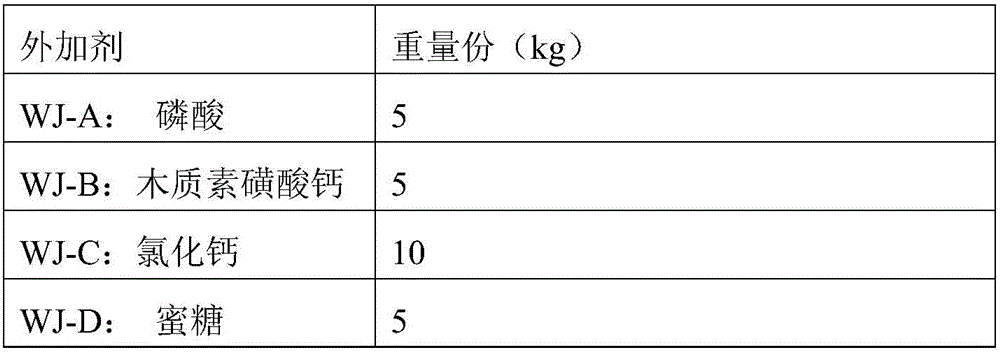

[0079] According to 1000 parts of the above-mentioned magnesium oxysulfide cement, add the admixtures shown in the weight parts of Table 1-2.

[0080] Table 1-2:

[0081]

[0082]

[0083] The preparation method steps are as follows:

[0084] Weigh each raw material according to the mass fraction in Table 1, dissolve magnesium sulfate in water, add various admixtures and stir evenly, add magnesium oxide, stir for 5Min, pour fly ash into and continue stirring to obtain a uniform cement slurry, add Quickly pour hydrogen peroxide into the slurry and stir quickly and evenly for 20 seconds, pour into the mold, let stand, and naturally cure for 15 minutes, demold, cut, and cure for 3 to 7 days to obtain low-density and high-strength magnesium oxysulfide foa...

Embodiment 2

[0089] In this embodiment, slag fine powder is used as lightweight aggregate, and the proportioning ratio of each raw material is shown in Table 3-1 and 3-2:

[0090] Table 3-1: Raw material ratio

[0091] raw material

parts by weight (kg)

MgO

300

MgSO 4

300

h 2 o

330

400

60

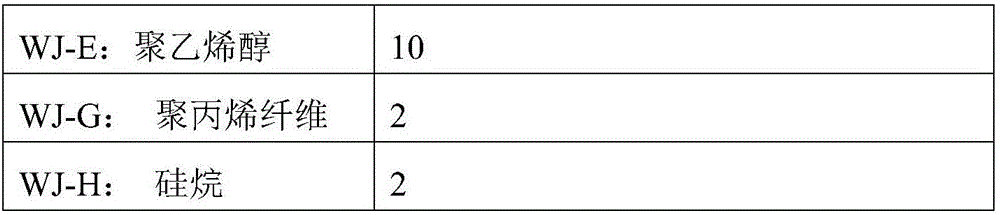

[0092] According to 1000 parts of the above-mentioned magnesium oxysulfide cement, add the admixture shown in Table 3-2 in parts by weight.

[0093] Table 3-2:

[0094] Admixture

parts by weight (kg)

WJ-A: phosphoric acid

5

WJ-B: Sodium lignosulfonate

5

WJ-C: sodium sulfate

10

WJ-D: Honey

5

WJ-E: Acrylamide

10

WJ-G: Hydroxypropyl methylcellulose

Vitamins

2

WJ-H: Silicone

2

[0095] The preparation method steps are as follows:

[0096] Weigh each raw material according to the mass fraction in Table 3, disso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com