Patents

Literature

39results about How to "Excellent) processability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flame retardant composition

InactiveUS20050228087A1Excellent processabilityEasy to processGroup 5/15 element organic compoundsHalogenEther

A flame-retardant composition comprises a polyphenylene ether resin having a number average molecular weight in terms of polystyrene of 500 to 5,000 and a phosphazene compound, the content of the polyphenylene ether being 20 to 95% by weight and that of the phosphazene compound being 80 to 5% by weight. The flame-retardant composition is excellent in processability when added to resins, and can provide a resin composition that contains no halogens and has an excellent balance of processability, heat resistance and flame retardancy.

Owner:ASAHI KASEI CHEM CORP

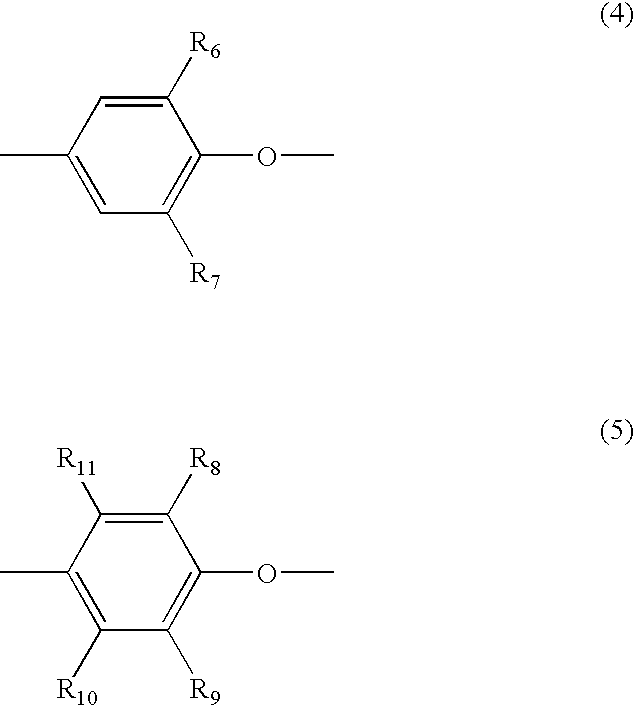

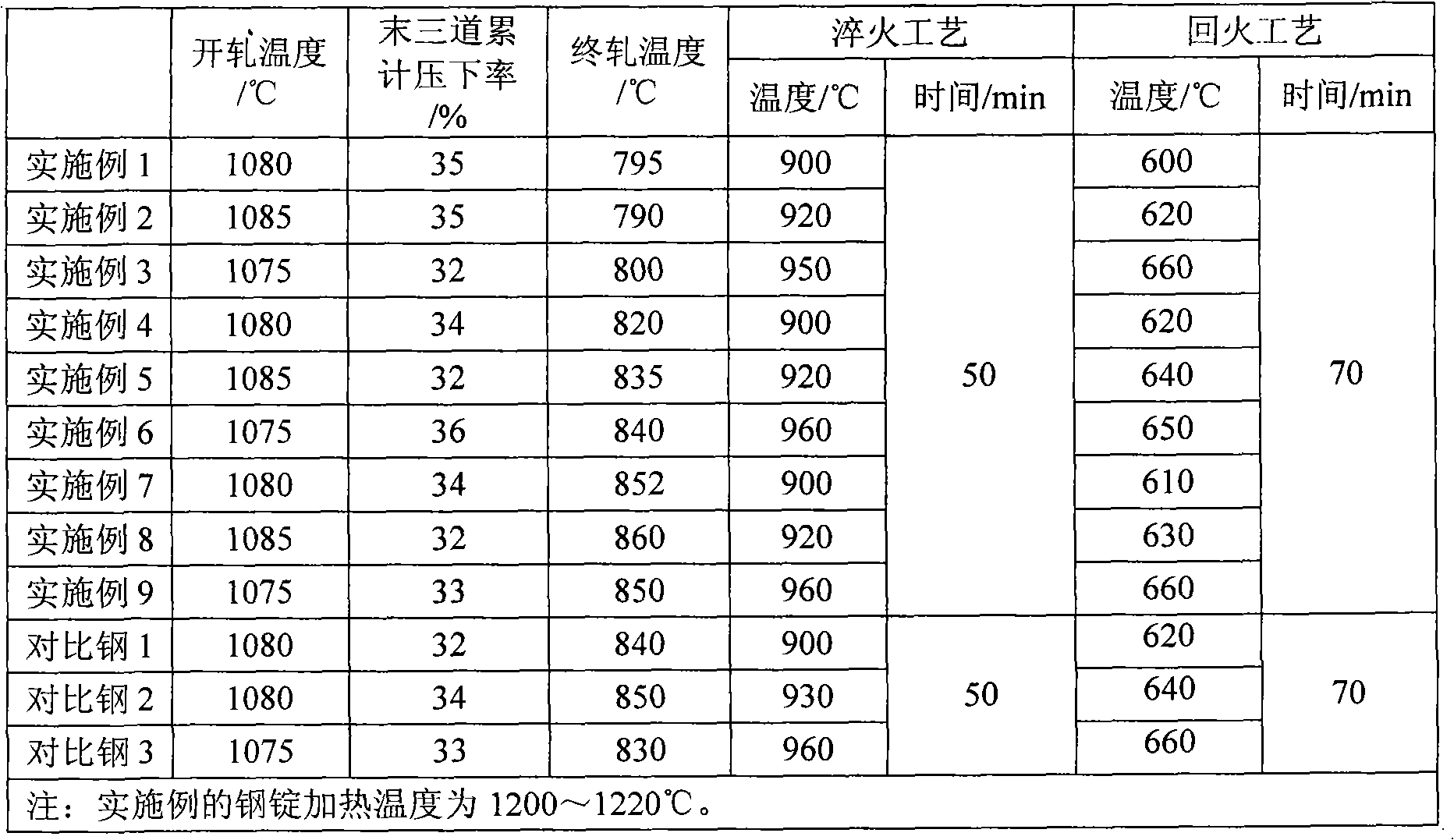

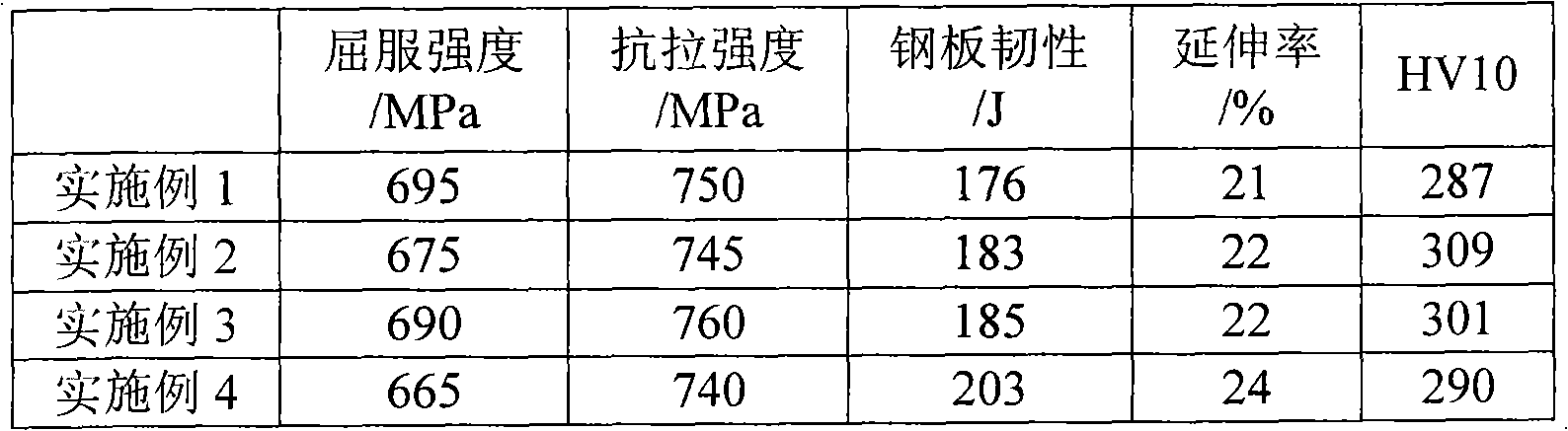

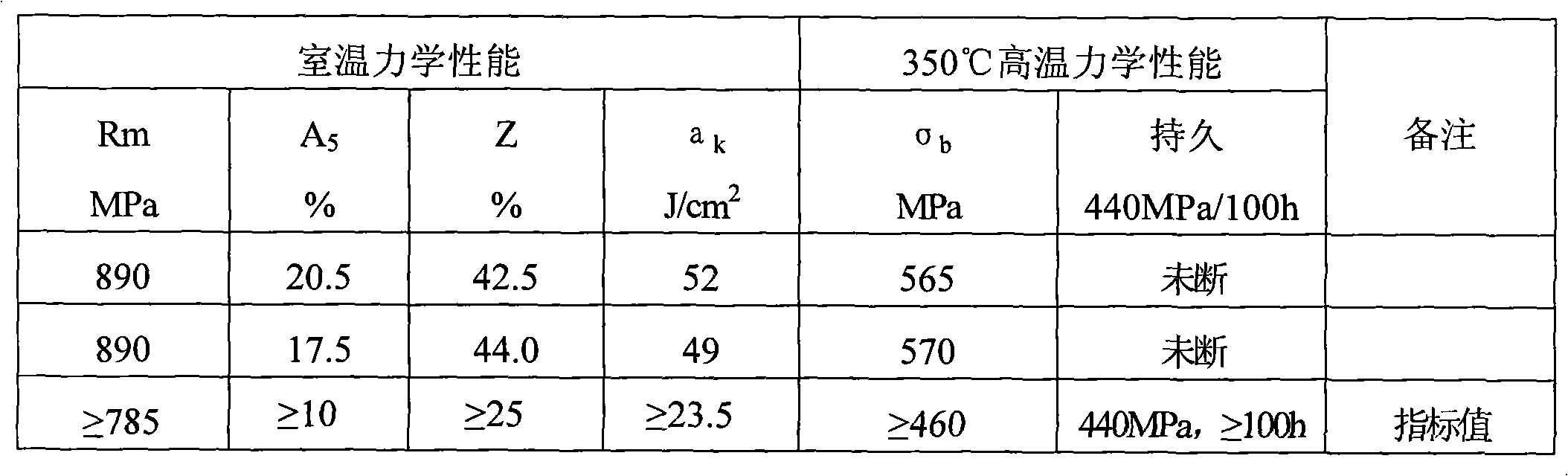

Low welding crack sensitivity steel with tensile strength at 700MPa level and production method thereof

ActiveCN101643888ATough enoughStrong enoughTemperature control deviceManufacturing convertersChemical compositionMetallurgy

The invention provides low welding crack sensitivity steel with tensile strength at a 700MPa level and a production method thereof. The steel comprises the following two or more chemical components inpercentage by weight: C: 0.08-0.12, Si: 0.15-0.40, Mn: 1.00-2.00, P: smaller than or equal to 0.015, S: smaller than or equal to 0.006, Ni: 0.25-0.55, Mo: 0.15-0.28, V: 0.02-0.10, Cu: 0.18-0.30, Cr:0.15-0.30, Ti: 0.008-0.020 and B: 0.0007-0.0027 as well as the balance of Fe and inevitable impurities and also satisfies that Pcm is smaller than or equal to 0.24 percent and satisfies an equation: Pcm=C+Si / 30+Mn / 20+Cu / 20+Cr / 20+Ni / 60+Mo / 15+V / 10+5B (percent). The invention adopts a deep molten iron desulphurization technology, a converter top and bottom converting, vacuum treatment and continuouscasting processes and carries out rolling and hardening, tempering and thermal treatment production according to a general clean steel process.

Owner:武汉钢铁有限公司

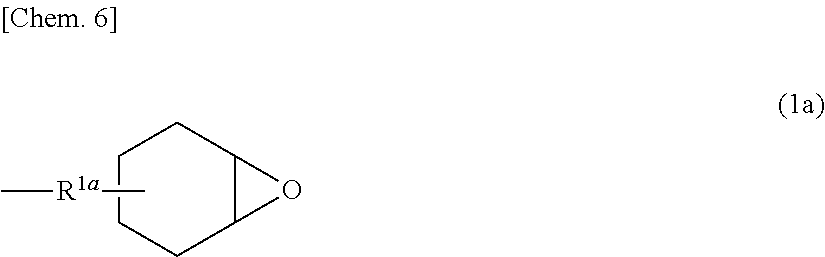

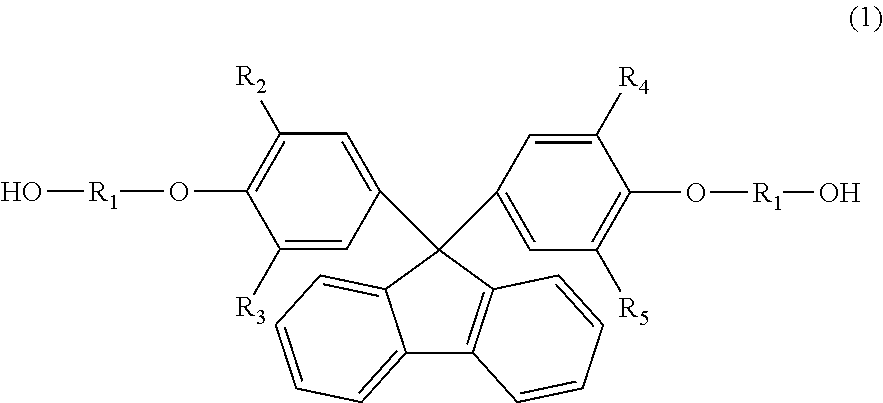

Polyorganosilsesquioxane, hard coat film, adhesive sheet, and laminate

InactiveUS20160297933A1Excellent processabilityHigh surface hardnessFilm/foil adhesivesAdhesive articlesHigh surfaceHardness

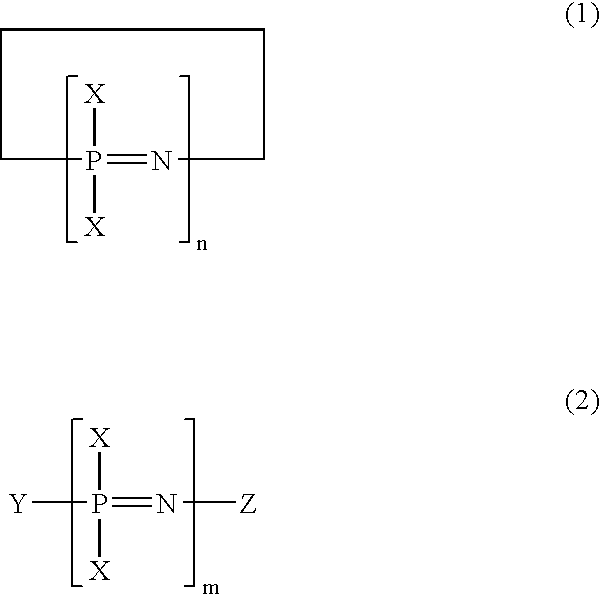

Provided is a polyorganosilsesquioxane capable of forming, when cured, a cured product that offers high surface hardness and good heat resistance, is highly flexible, and has excellent processability. The present invention relates to a polyorganosilsesquioxane including a constitutional unit represented by Formula (1). The polyorganosilsesquioxane includes a constitutional unit represented by Formula (I) and a constitutional unit represented by Formula (II) in a mole ratio of the constitutional unit represented by Formula (I) to the constitutional unit represented by Formula (II) of 5 or more. The polyorganosilsesquioxane has a total proportion of the constitutional unit represented by Formula (1) and a constitutional unit represented by Formula (4) of 55% to 100% by mole based on the total amount (100% by mole) of all siloxane constitutional units. The polyorganosilsesquioxane has a number-average molecular weight of 1000 to 3000 and a molecular-weight dispersity (weight-average molecular weight to number-average molecular weight ratio) of 1.0 to 3.0.[R1SiO3 / 2] (1)[Chem. 2][RaSiO3 / 2] (I)[Chem. 3][RbSiO(ORc)] (II)[Chem. 4][R1SiO(ORc)] (4)

Owner:DAICEL CHEM IND LTD

Thermoplastic Elastomer Composition and Molded Article Thereof

There is provided a thermoplastic elastomer composition including an ethylene / α-olefin copolymeric rubber (A1) or an extended rubber (X) comprising an ethylene / α-olefin copolymeric rubber (A2) and a mineral oil softener (E2), and a thermoplastic α-olefin resin (B) comprising a α-olefinic crystalline thermoplastic resin (B1) and / or a α-olefinic amorphous thermoplastic resin (B2), an unmodified organopolysiloxane (C), a viny-terminated organopolysiloxane (D), and a mineral oil softener (E1); and molded article produced by forming the thermoplastic elastomer composition. There is provided a thermoplastic elastomer composition and a molded article thereof having excellent molding appearance by imparting an initial sliding ability with an organopolysiloxane having low viscosity and by adding a crosslinked vinylated organopolysiloxane to a thermoplastic elastomer composition to exhibit durable abrasion resistance (long term sliding ability).

Owner:JSR CORPORATIOON

Cutting-resistant ultra high molecular weight polyethylene fiber, preparation method and application thereof

ActiveCN106350882AImprove cut resistanceExcellent processabilitySpinnerette packsWet spinning methodsFiberMohs scale of mineral hardness

The invention relates to cutting-resistant ultra high molecular weight polyethylene fiber, a preparation method and application thereof. The cutting-resistant ultra high molecular weight polyethylene fiber is endless tow or / and short fiber in morphology; the matrix of the polyethylene fiber comprises rodlike particles; the Moh's hardness of each rodlike particle is of grade 3 and above (one with high hardness is preferred); the length-diameter ratio of each rodlike particle is greater than or equal to 2 micrometers; the diameter of each rodlike particle is smaller than 30 micrometers. By adopting the cutting-resistant ultra high molecular weight polyethylene fiber, the cutting resistance of high molecular weight polyethylene fiber and a fabric of the high molecular weight polyethylene fiber can be improved, the fiber has post processing properties prior to those of conventional cutting-resistant fiber of a same grade and fabrics of the conventional cutting-resistant fiber, and the cost can be lowered.

Owner:CHANGSHU SUPERFIBER

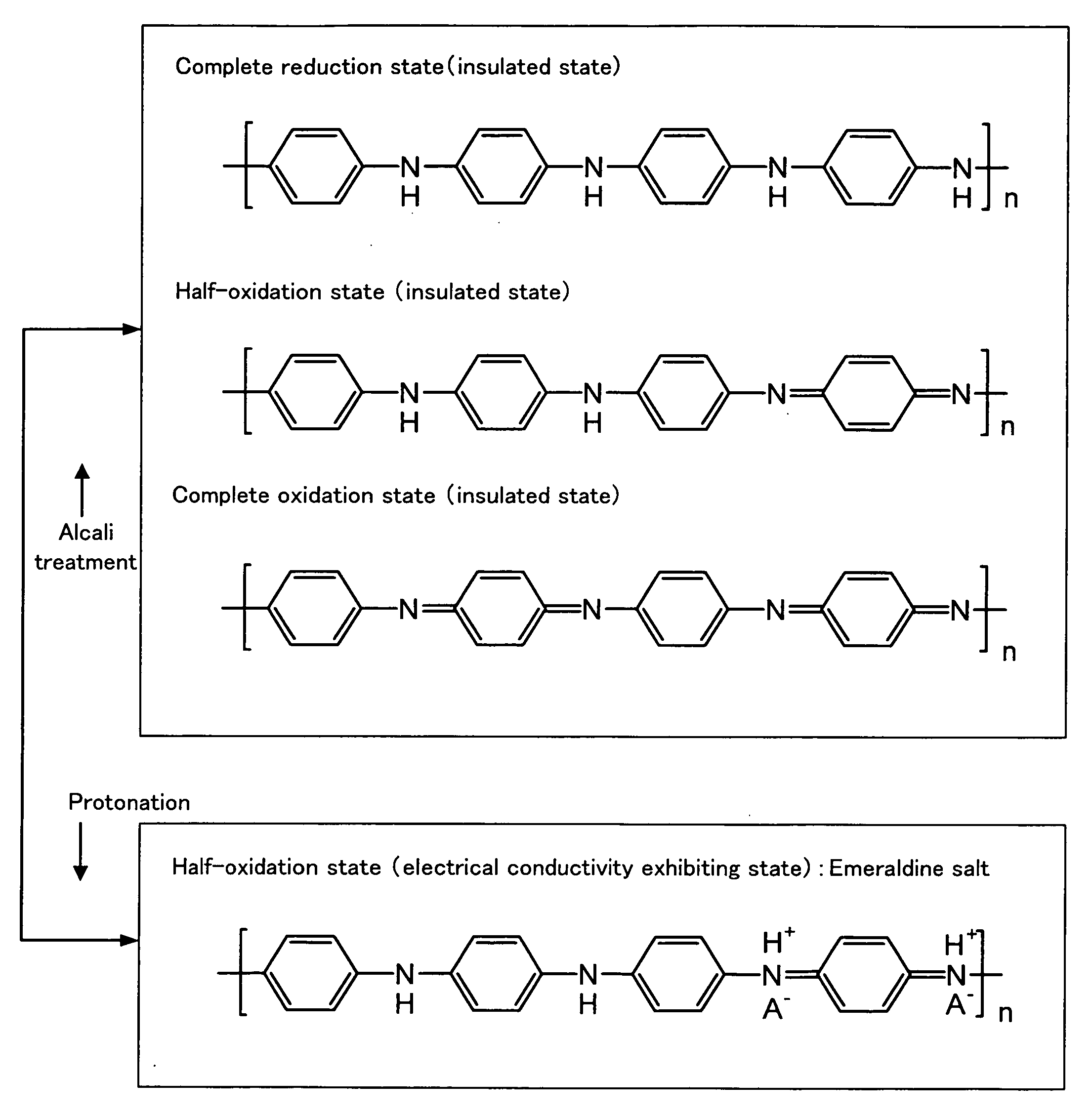

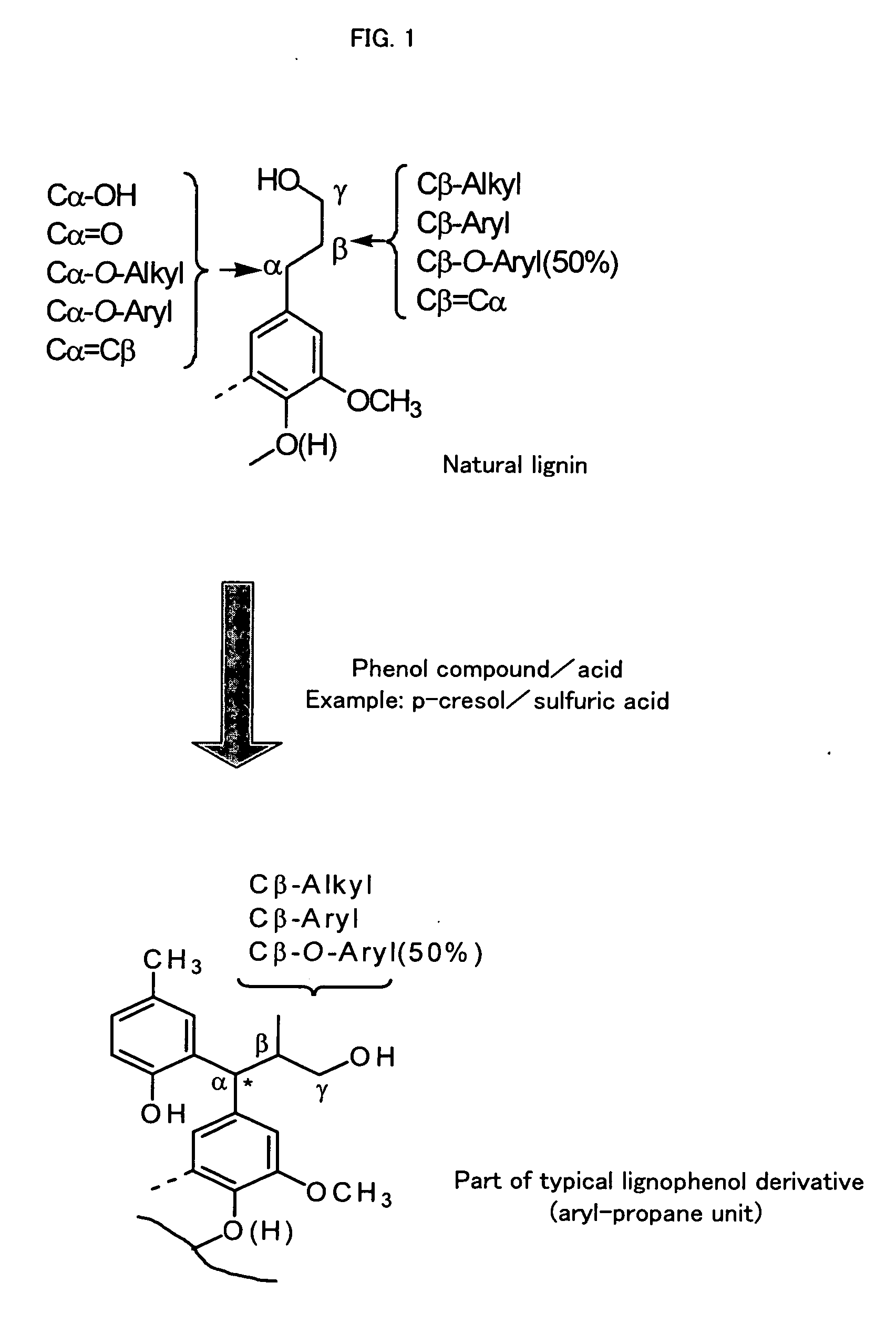

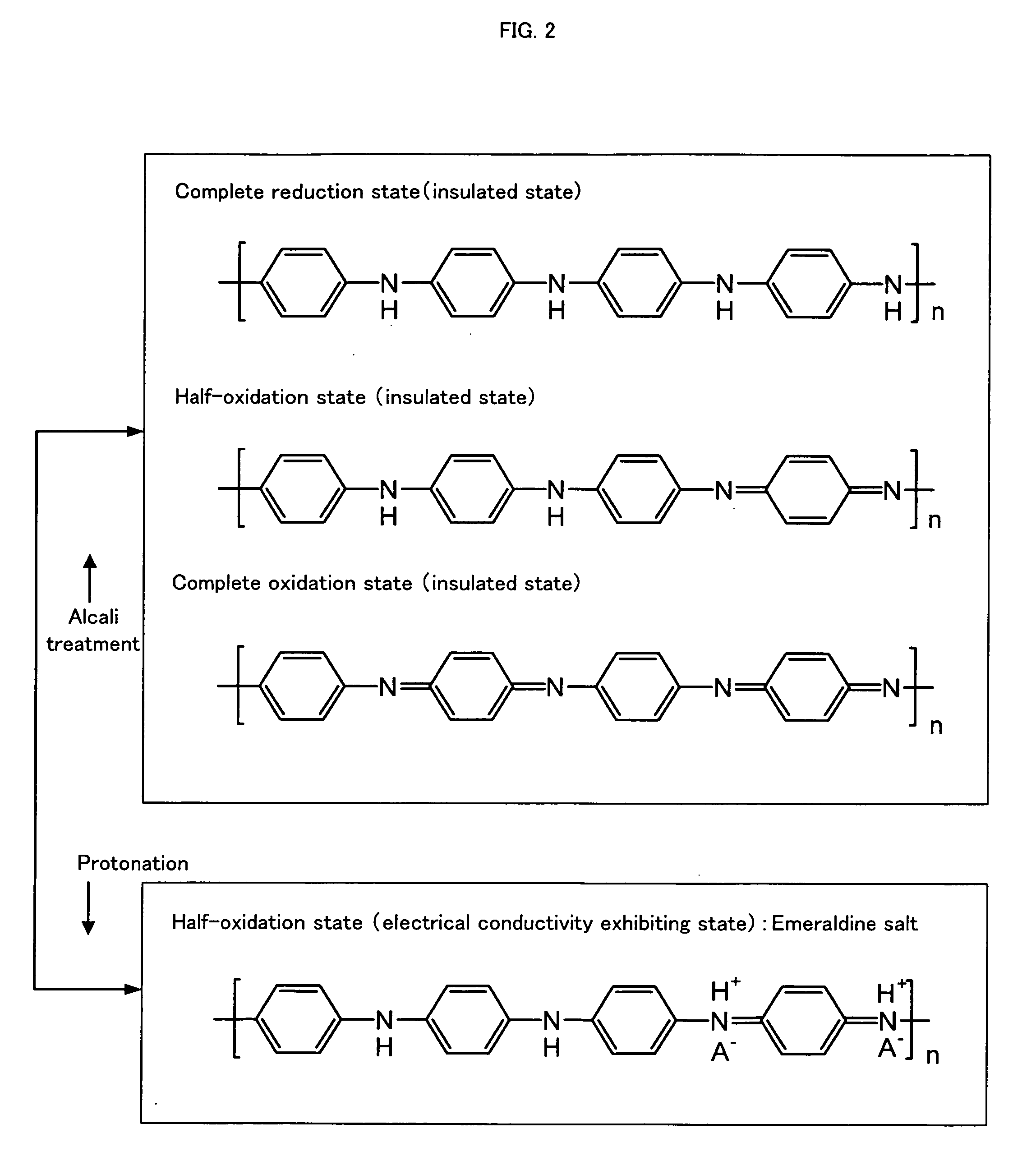

Electrically Conductive Polyaniline Composition, Process for Producing the Same and Polyaniline Dopant

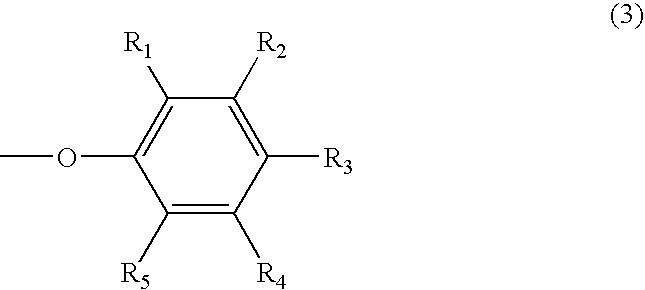

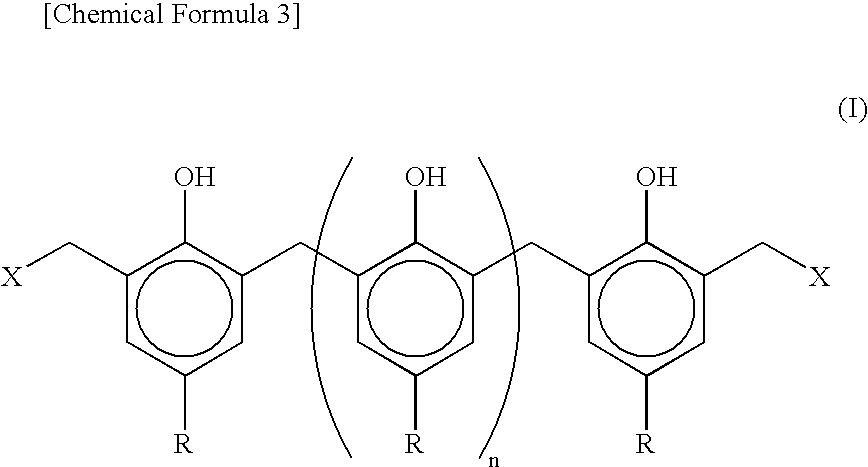

InactiveUS20080017832A1Small environmental loadExcellent processabilityConductive materialOrganic conductorsPhenolsPhenol derivative

The invention provides a polyaniline dopant which has small environmental load and from which an electrically conductive polyaniline having better processability on polyaniline can be obtained. A phenol derivative of lignin having a bis(aryl)propane unit in which a carbon atom on an ortho-position and / or a para-position relative to a phenolic hydroxy group of a phenol compound is bound to a carbon atom on a C1-position of an aryl propane unit of lignin is used as a polyaniline dopant. Since a phenol derivative of lignin is derived from a source that can be recycled, the dopant is a polyaniline dopant having small environmental load.

Owner:JAPAN SCI & TECH CORP

Thermoplastic resin composition

InactiveUS7354968B2Highly flexibleExcellent processabilityConductive materialMixingSpecific gravityPliability

The present invention provides a thermoplastic resin composition having a high specific gravity, flexibility and excellent processability that can be used as a material for forming various articles requiring both massiveness and flexibility. This thermoplastic resin composition contains 2.5 to 15 wt % of a styrene-based thermoplastic elastomer and 85 to 97.5 wt % of tungsten powder, and an molded article is obtained by melting and kneading this thermoplastic resin composition. This article can be used preferably as a balance weight attached to a wheel of an automobile, sports goods or the like.

Owner:SUMITOMO RUBBER IND LTD

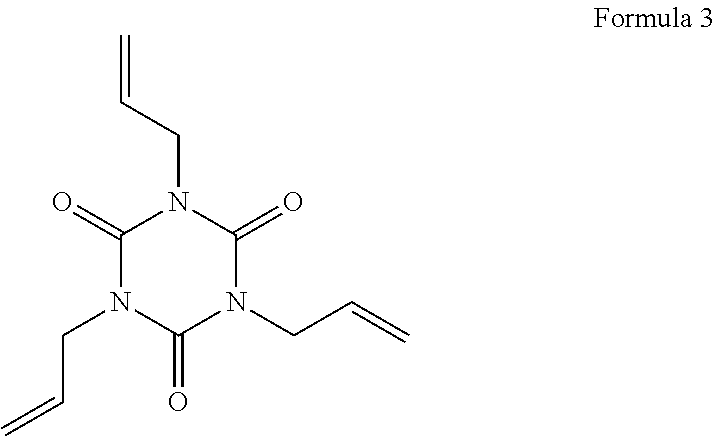

Resin compositions for polymer solid electrolytes as well as polymer solid electrolytes and polymer batteries using them

InactiveUS7033706B2High ionic conductivityExcellent processabilitySolid electrolytesHybrid capacitor electrolytesPolymer chemistryPlasticizer

Polymer solid electrolytes with good film strength, high ionic conductivity and excellent processability are provided, comprising a resin composition for polymer solid electrolytes containing 0.5–5.0% by weight of a curable resin having a specific structure (A), a plasticizer and (B) an electrolyte (C).

Owner:NIPPON KAYAKU CO LTD

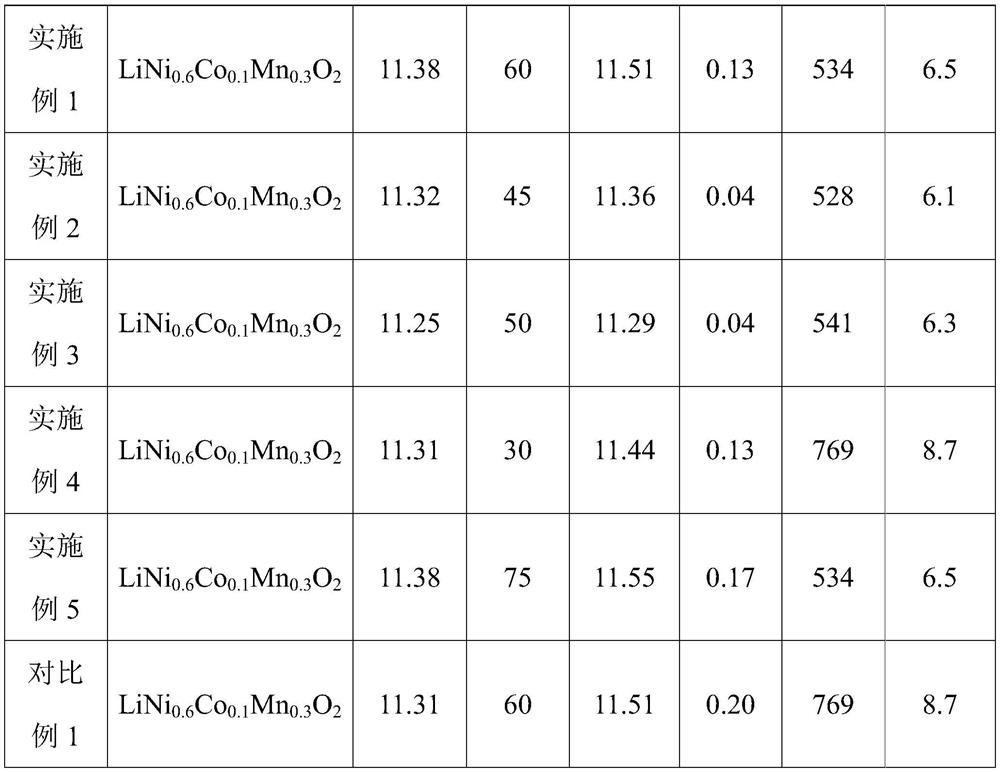

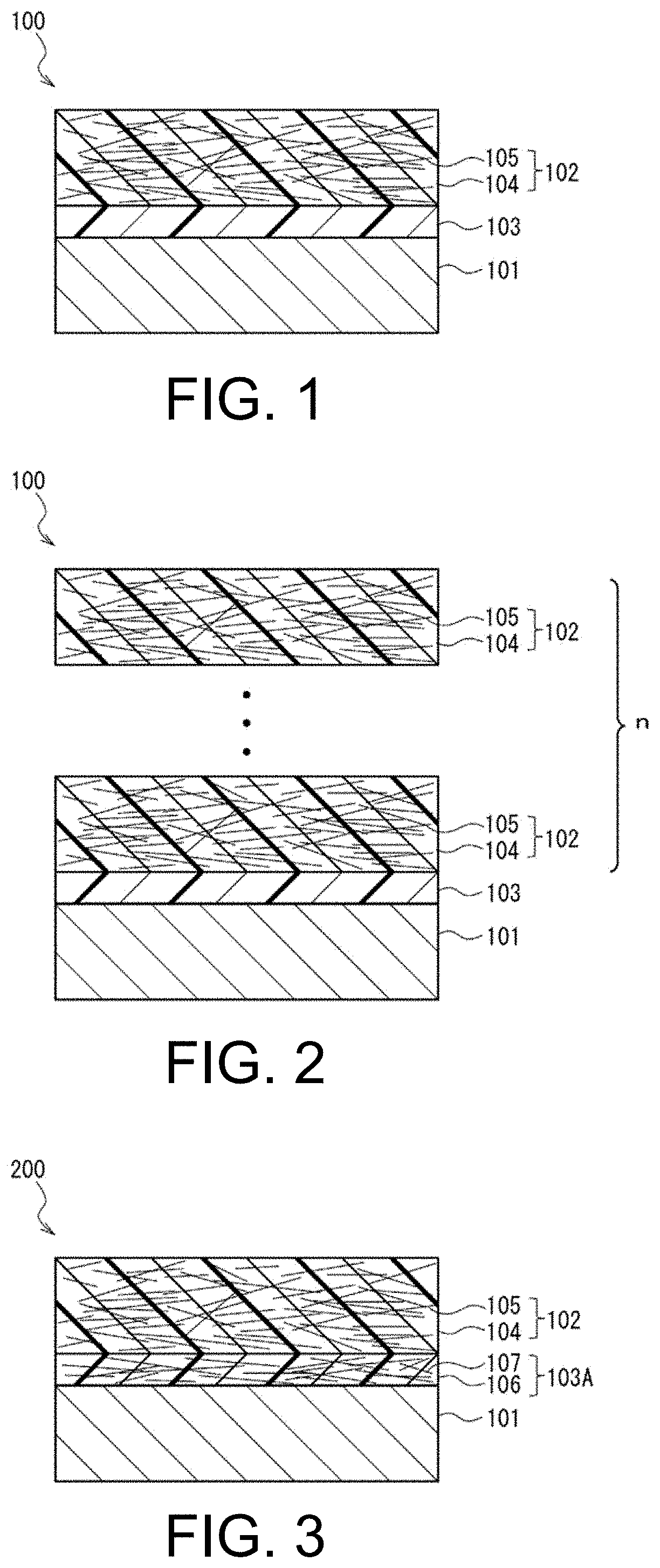

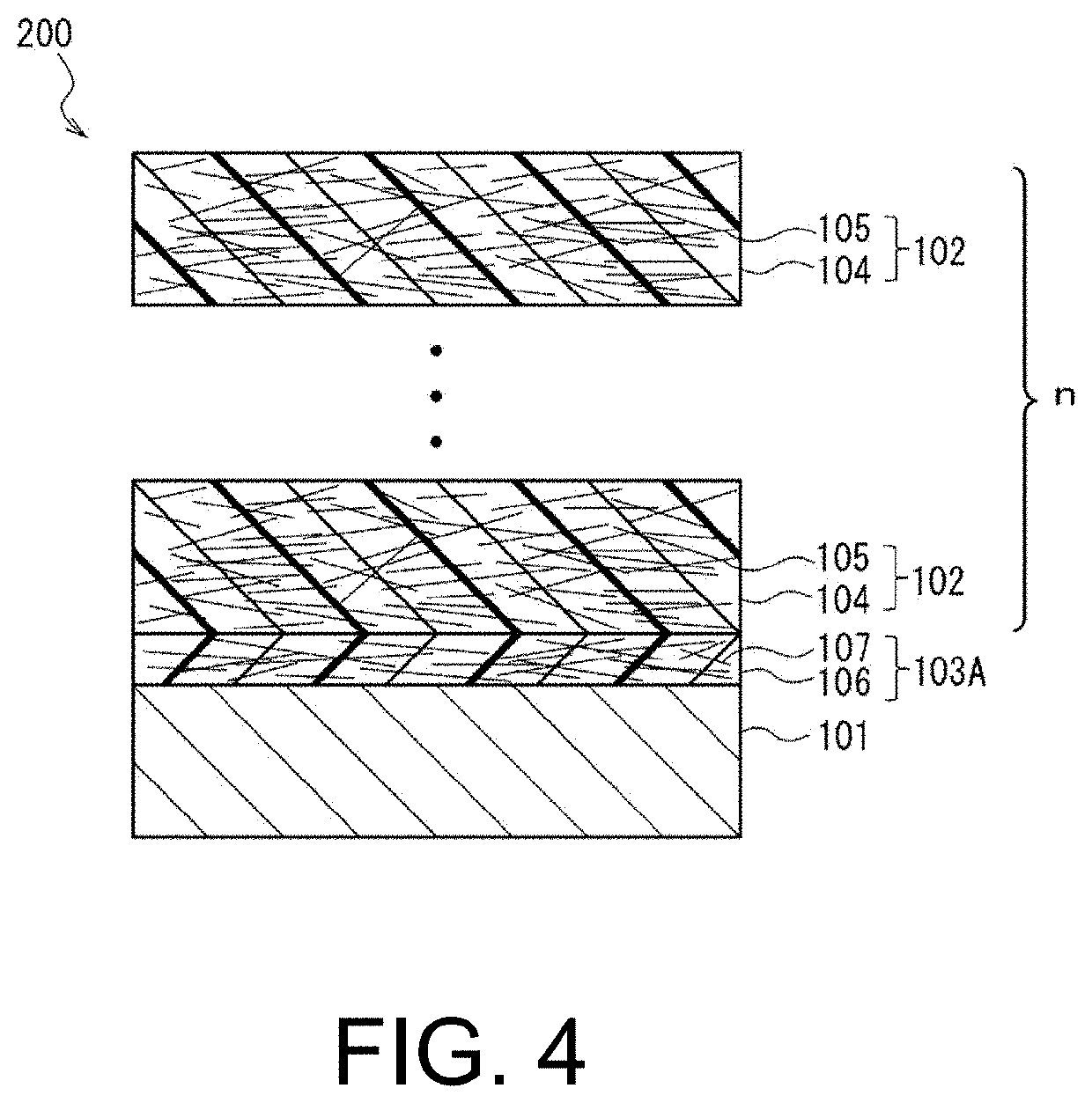

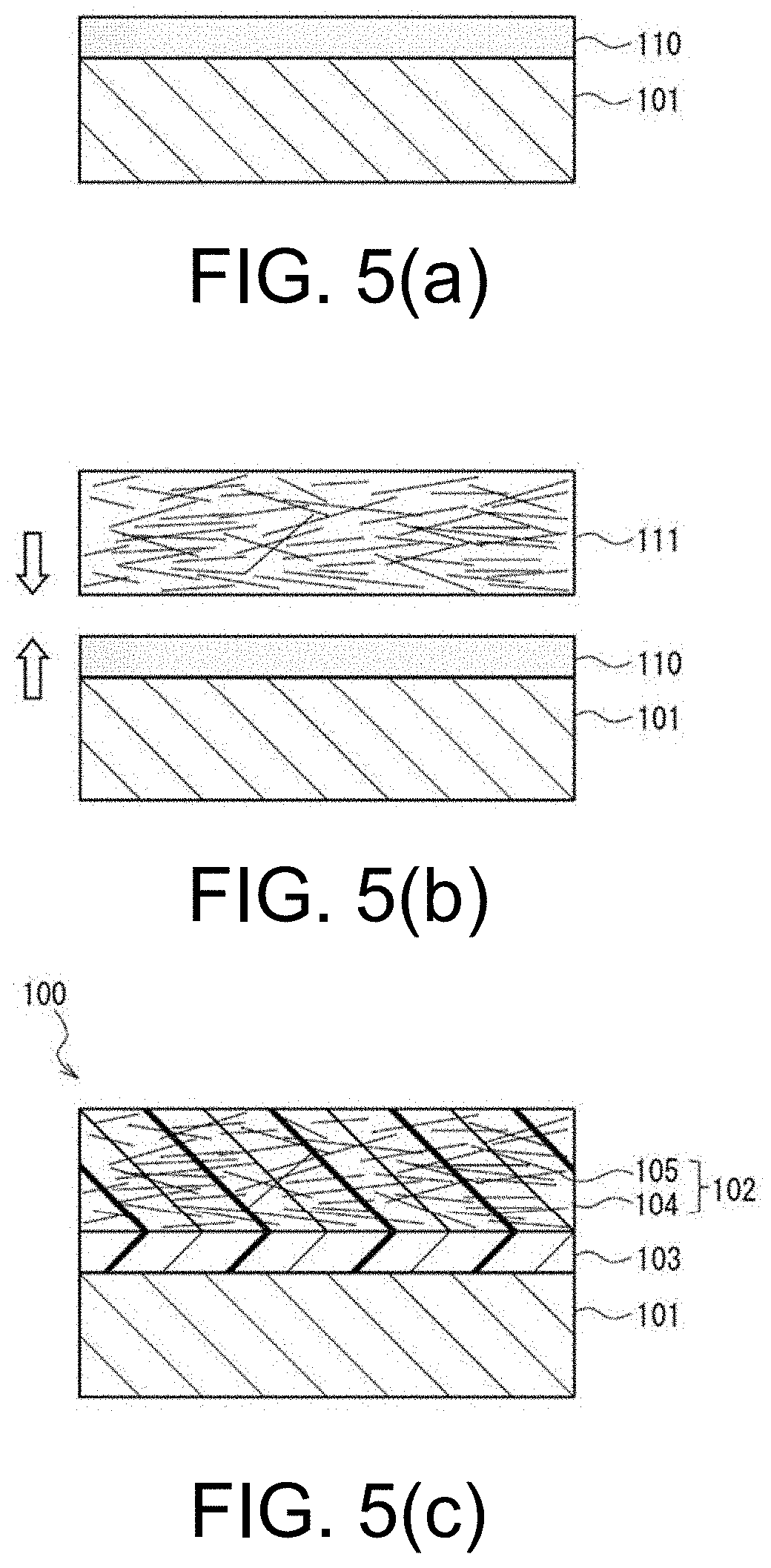

Biaxially stretched laminated polyester film, infrared light shielding structure for laminated glass composed of the same, and laminated glass composed of the same

ActiveUS20140327958A1High performanceExcellent processabilityMirrorsAntiglare equipmentReflectivityPolyester

Provided are a biaxially stretched laminated polyester film and a laminated glass composed of the same. Specifically, the invention is achieved by a biaxially stretched laminated polyester film including 51 layers or more in total, in which a first layer and a second layer are alternately laminated, wherein a polyester (A) constituting the first layer is polyethylene-2,6-naphthalenedicarboxylate; a polyester (B) constituting the second layer is a polyester containing at least one of an ethylene terephthalate component and an ethylene naphthalene dicarboxylate component; an average reflectance within a wavelength range of 400 to 750 nm is not more than 25%; an average reflectance within a wavelength range of 800 to 1,200 nm is 50% or more; and a Young's modulus of the film at 90° C. is 2,400 MPa or more in at least one direction of the longitudinal direction and the lateral direction of the film.

Owner:TEIJIN DUPONT FILMS JAPAN

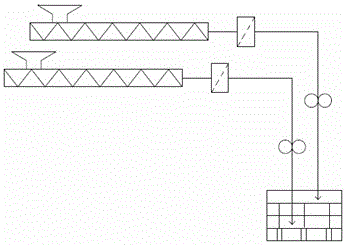

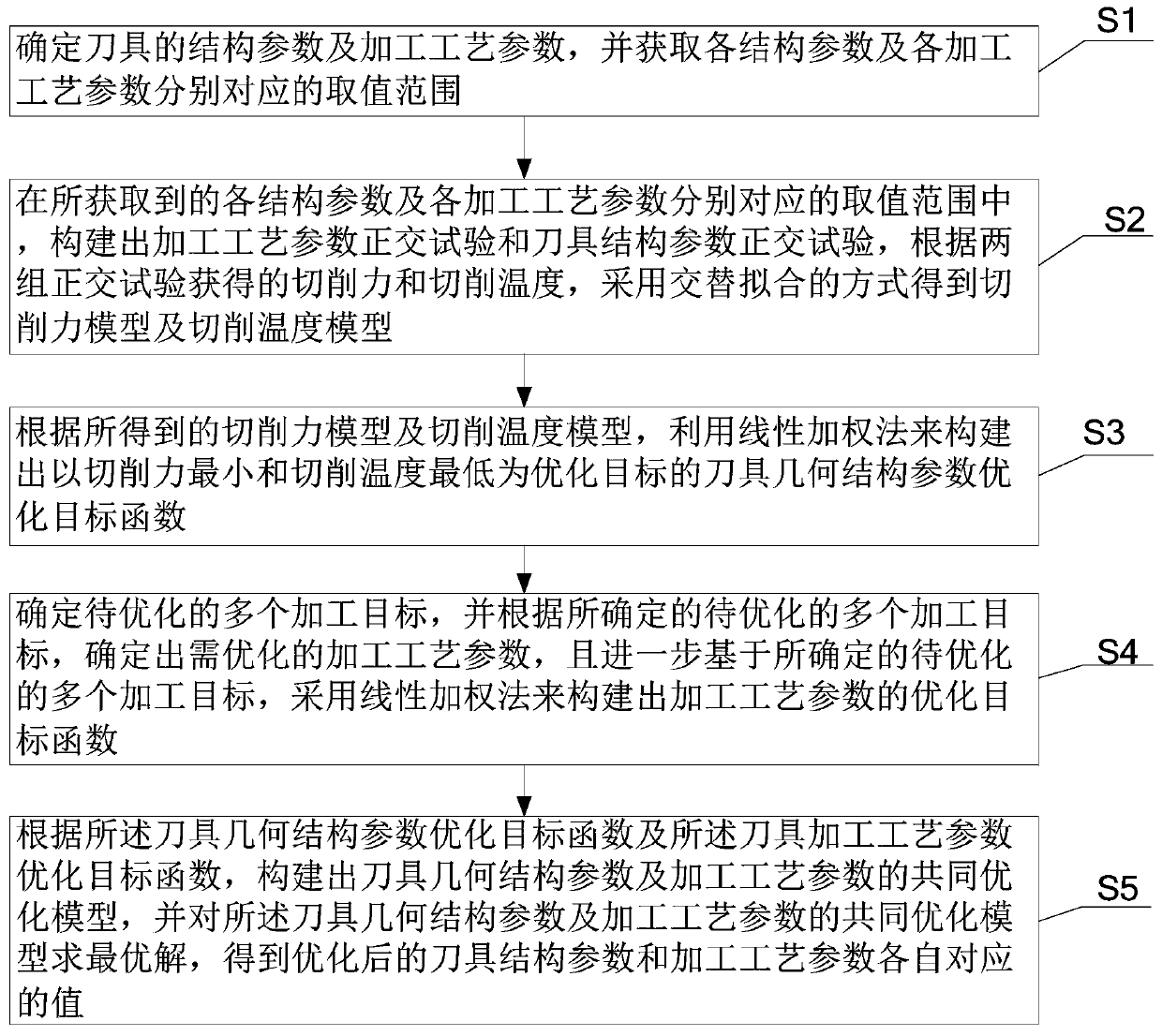

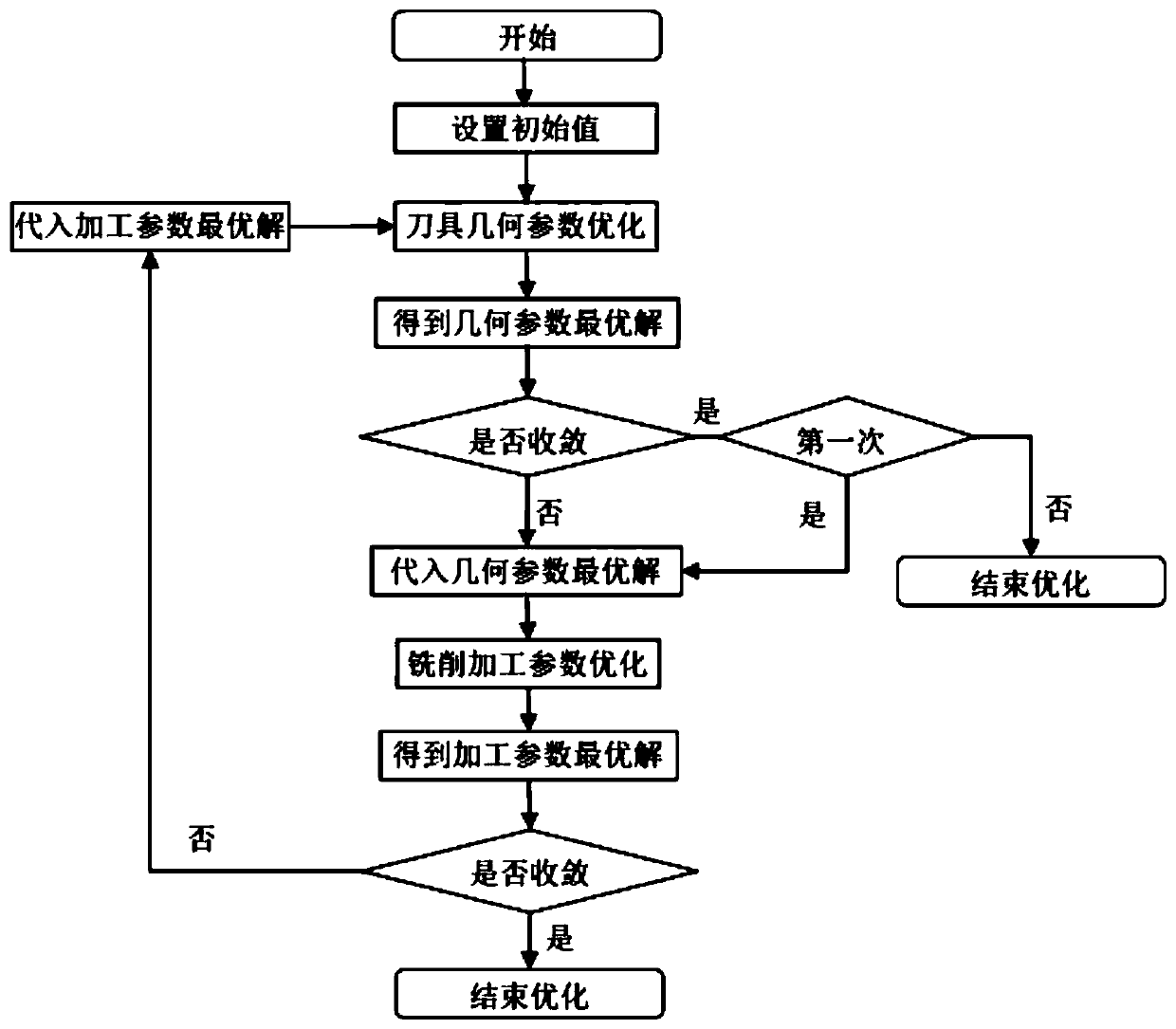

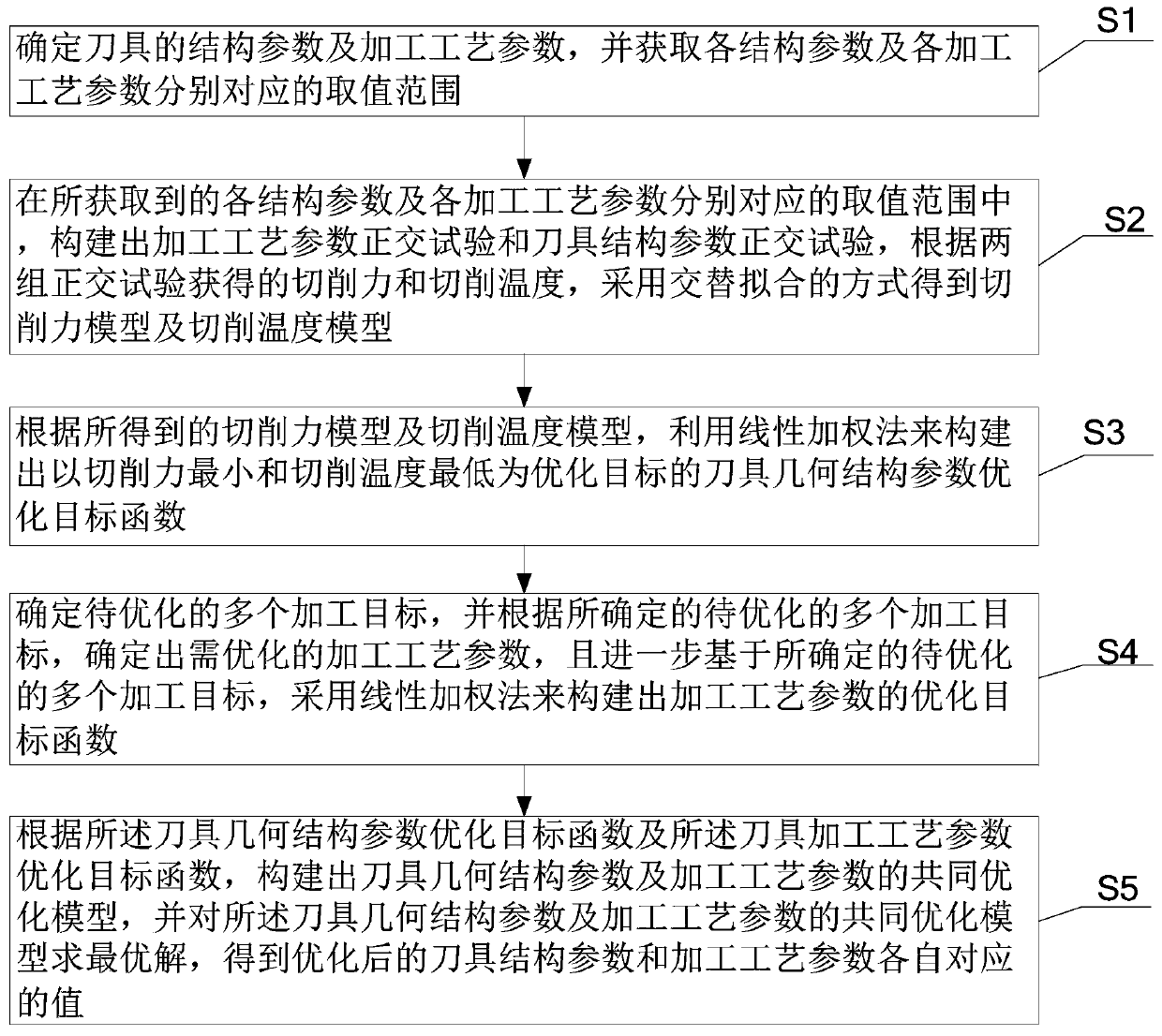

Method for jointly optimizing tool geometry parameters and machining process parameters

ActiveCN109839895AExcellent structureExcellent processabilityNumerical controlCutting force modelProcess engineering

The invention provides a method for jointly optimizing tool geometry parameters and machining process parameters. The method comprises the steps that structural parameters of a tool, machining processparameters and respective ranges of values are determined; the orthogonal test of the machining process parameters and the orthogonal test of the structural parameters of the tool are constructed inrespective ranges of values; a cutting force model and a cutting temperature model are acquired according to the cutting force data and cutting temperature data acquired by two orthogonal tests; according to the cutting force model and the cutting temperature model, the optimization objective function of the geometry structural parameters of the tool is constructed; according to a machining targetto be optimized, the machining process parameters to be optimized are determined, and the optimization objective function of the machining process parameter is constructed; and according to the abovetwo optimization objective functions, a common optimization model is constructed, and the optimal solution is acquired to acquire corresponding values of the optimized tool structural parameters andmachining process parameters. According to the invention, each machining target in the actual machining process is comprehensively considered, and the optimal tool structural parameters and machiningprocess parameters are acquired.

Owner:WENZHOU UNIVERSITY

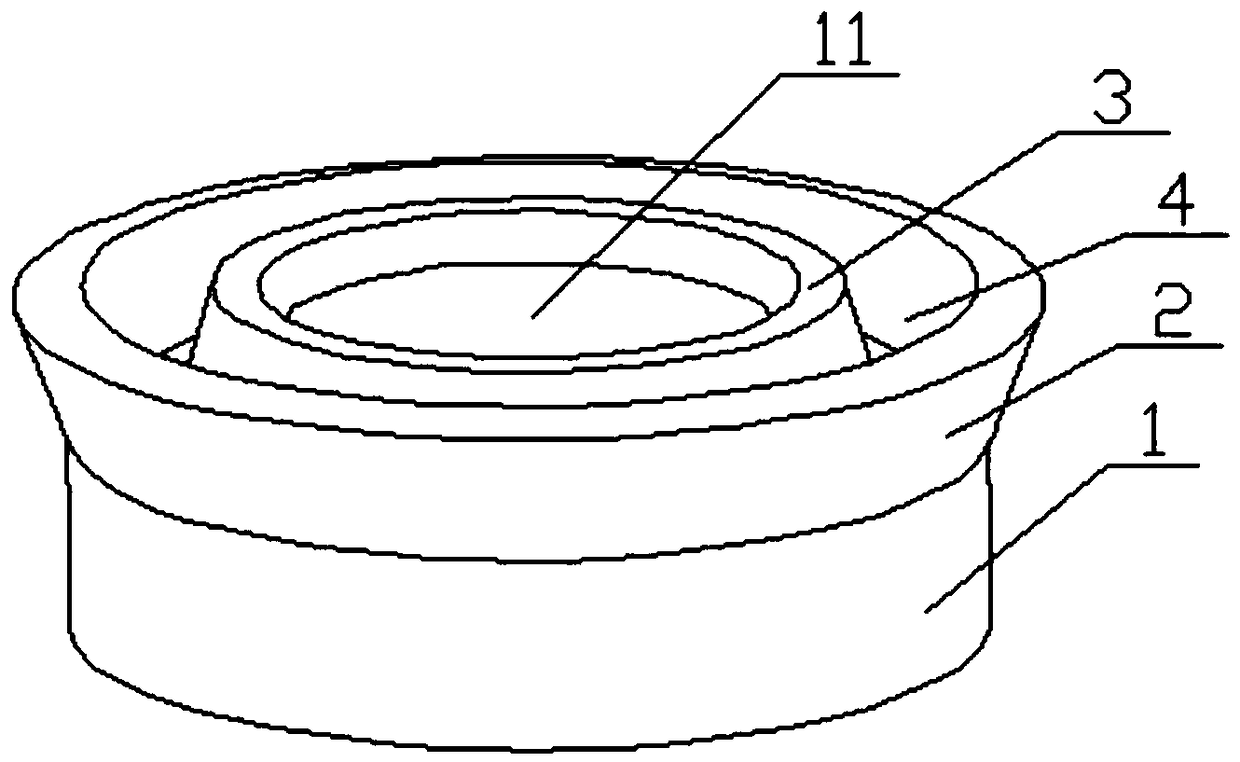

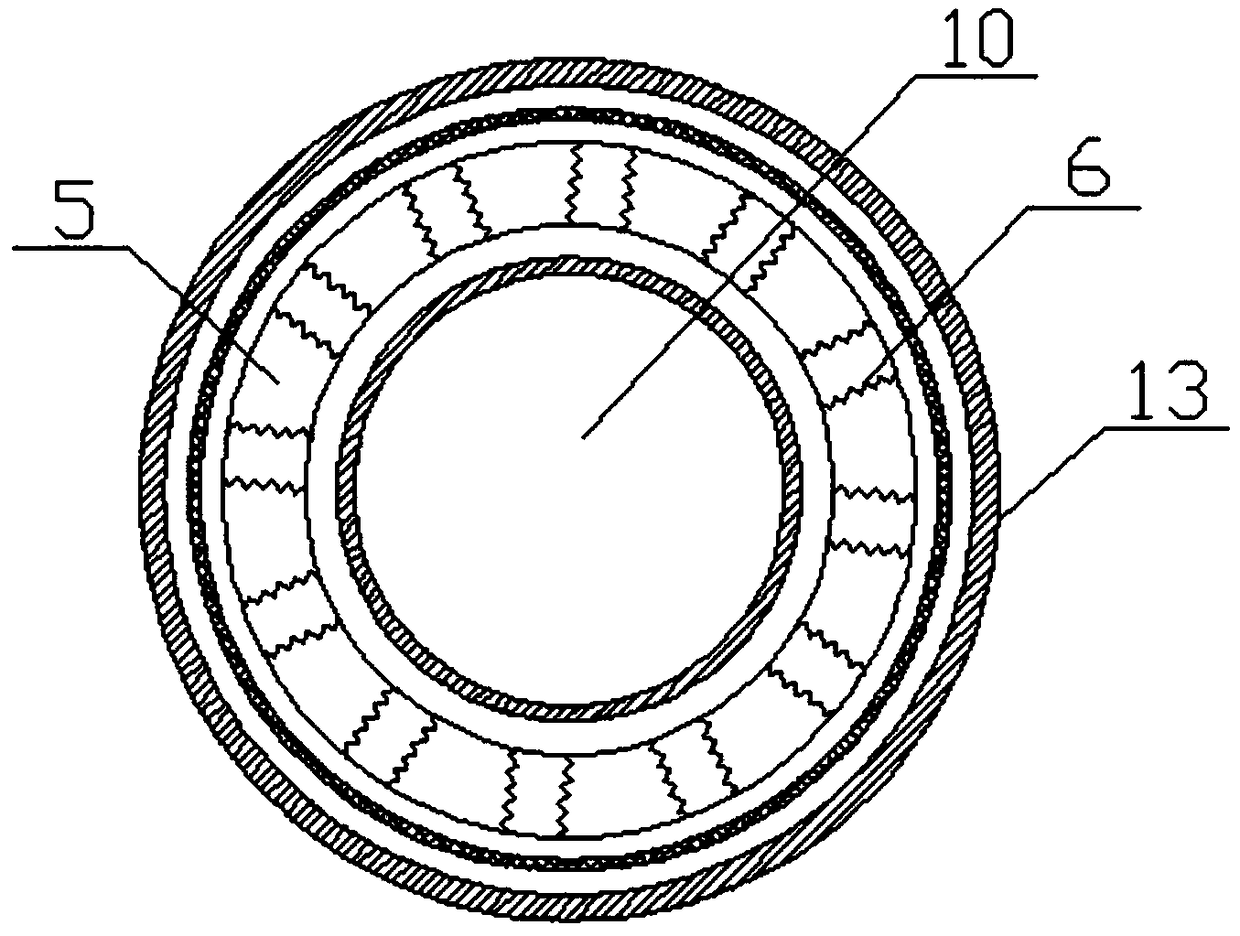

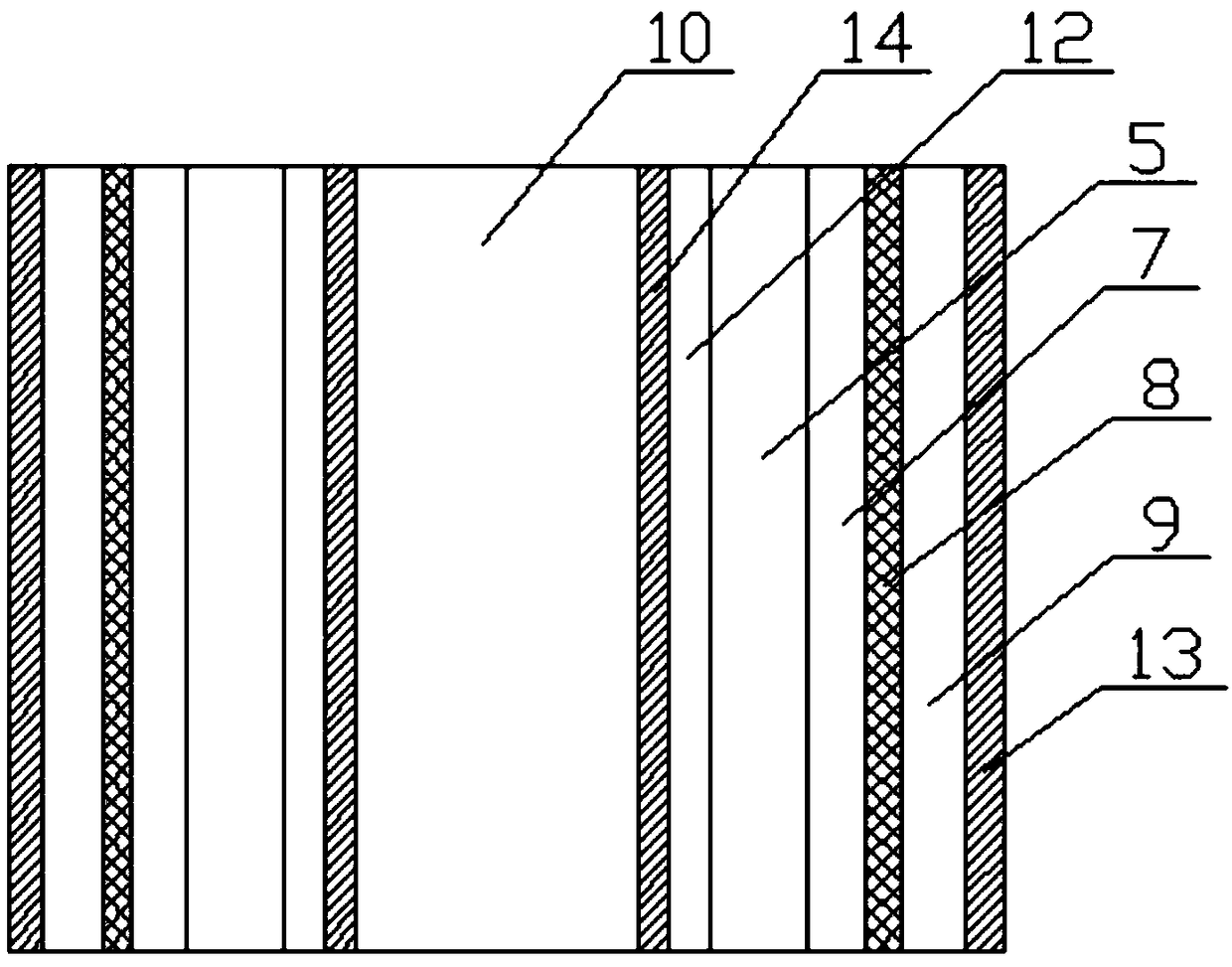

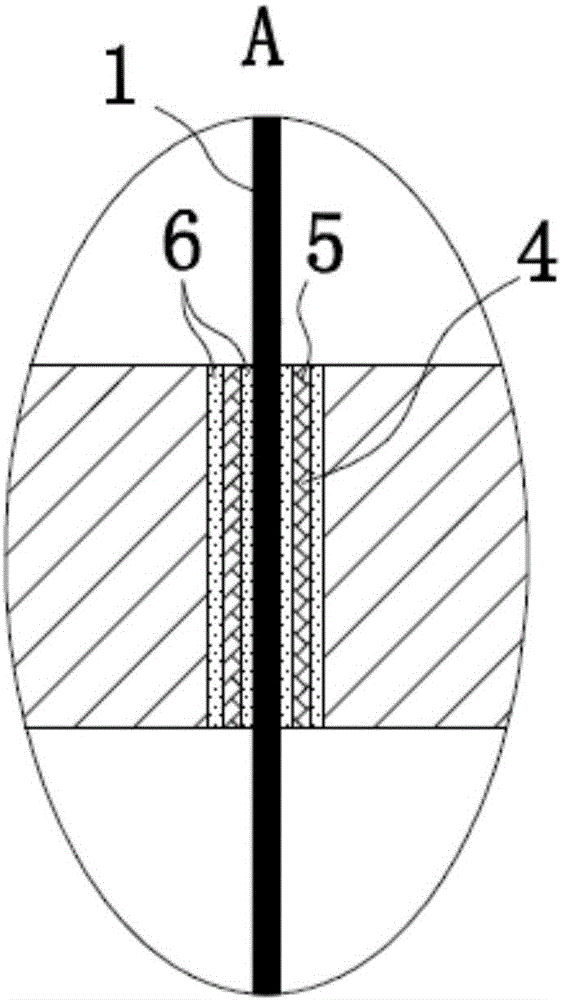

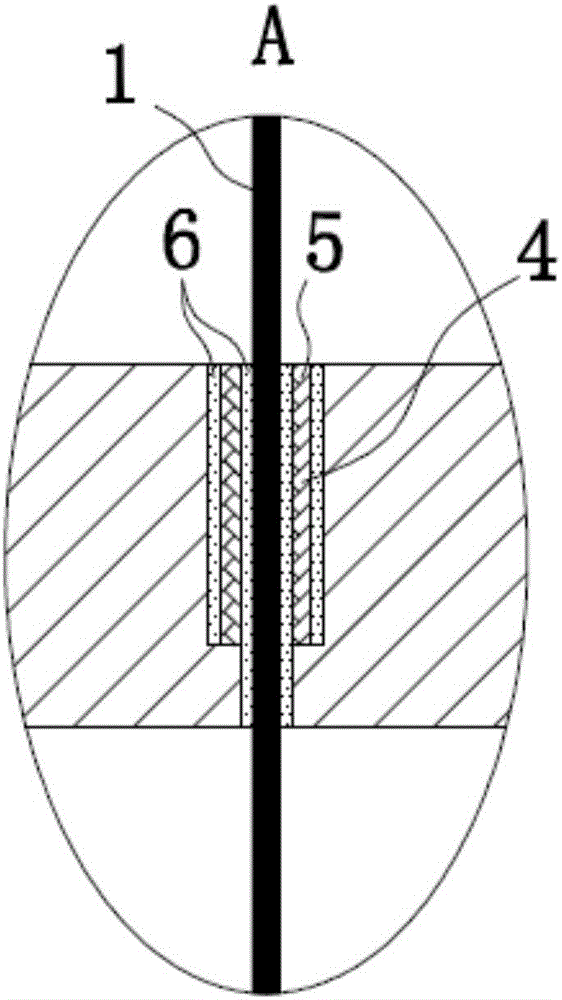

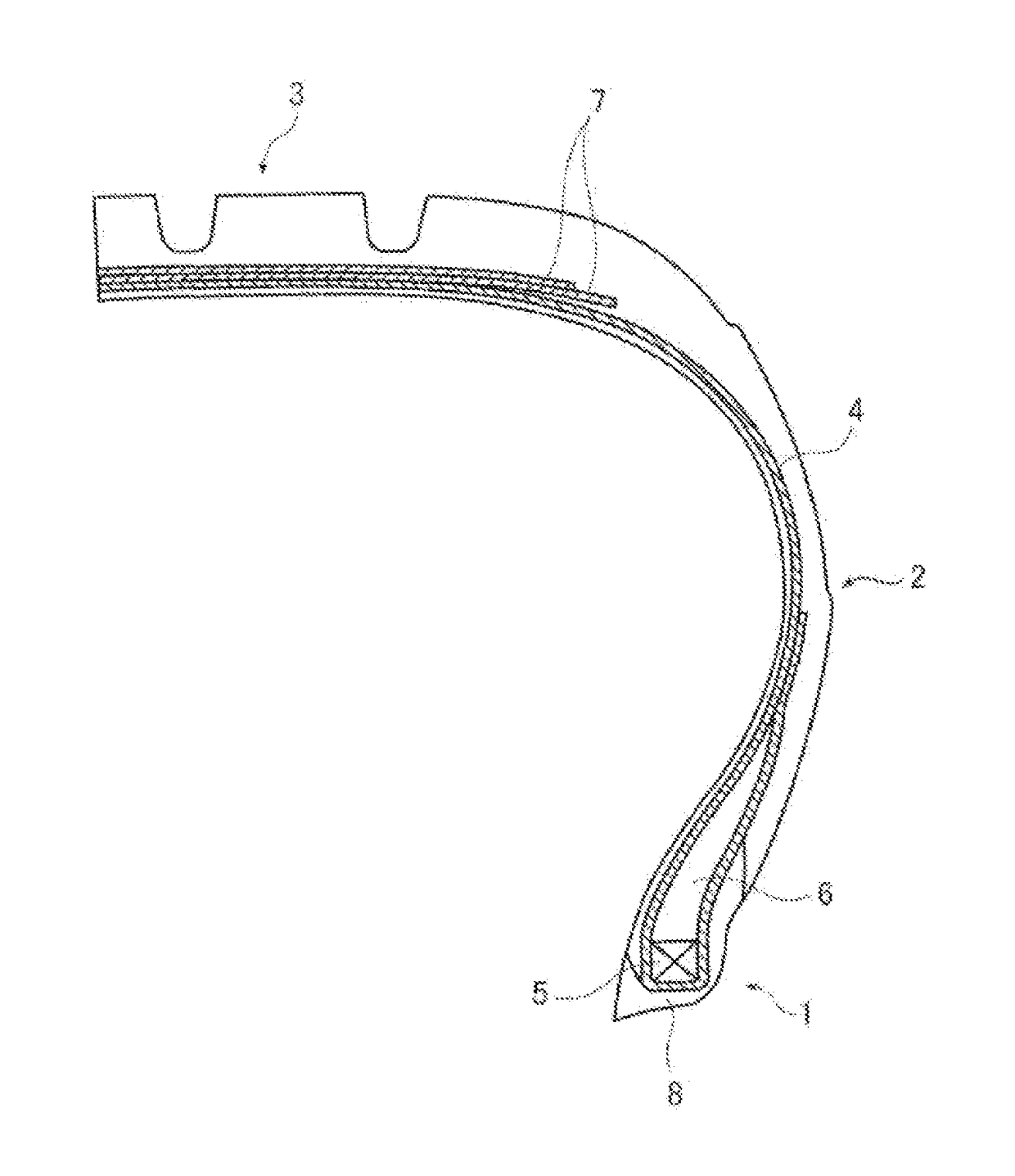

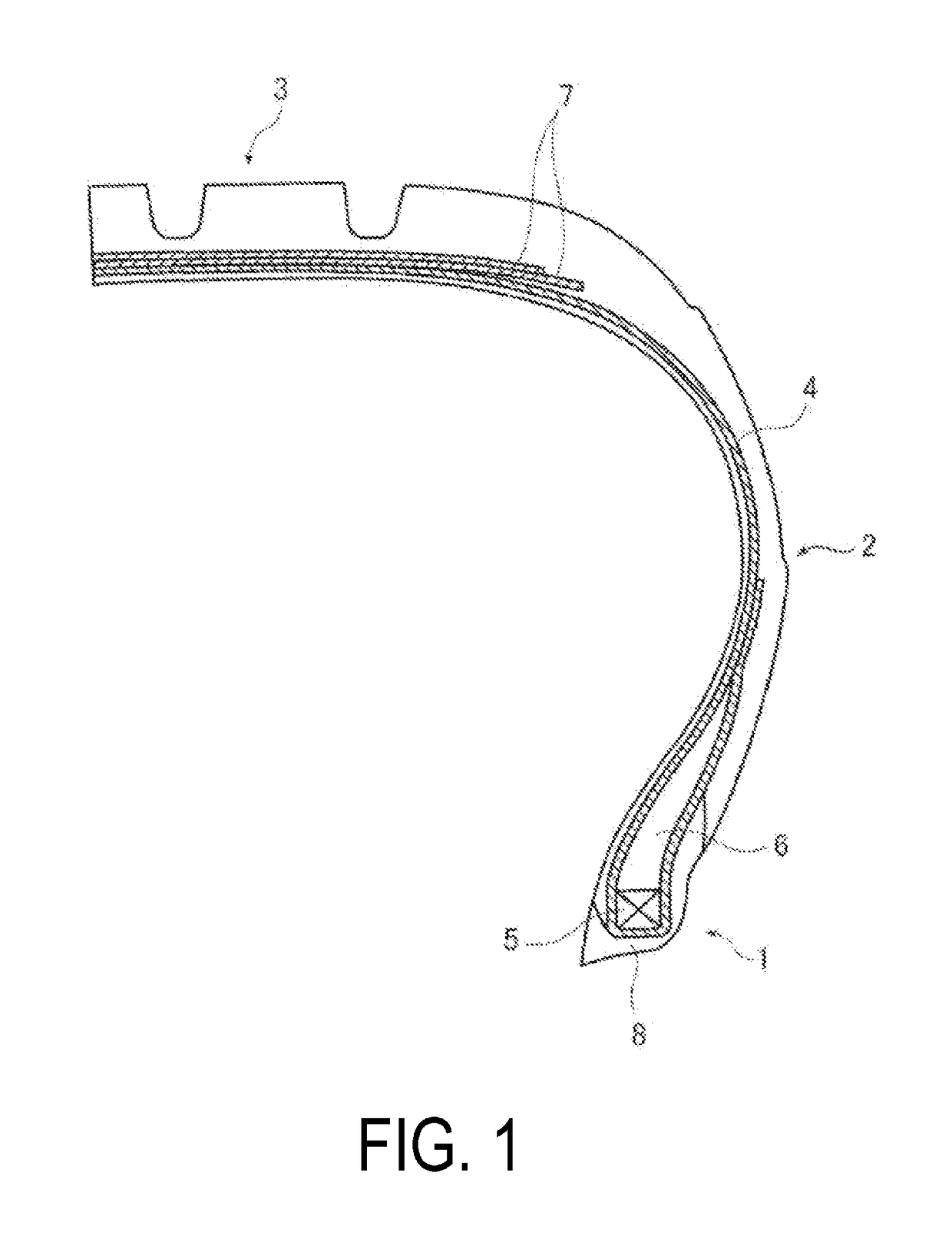

Automobile rubber sealing ring

The invention discloses an automobile rubber sealing ring and relates to the technical field of rubber sealing rings. The automobile rubber sealing ring comprises a sealing ring body, an outer sealinglip and an inner sealing lip. The upper surface of the sealing ring body is fixedly connected with the outer sealing lip, the middle position of the outer sealing lip is fixedly connected with the inner sealing lip, and a groove is formed between the inner sealing lip and the outer sealing lip. A first rubber layer is arranged in the sealing ring body, elastic reinforcing ribs are evenly buried in the first rubber layer, a second rubber layer is evenly wrapped on the outer wall of the first rubber layer, a metal ring frame is evenly wrapped on the outer wall of the second rubber layer, the inner wall of the metal ring frame is fixedly connected with the outer wall of the second rubber layer, and a third rubber layer is evenly wrapped on the outer wall of the metal ring frame. The automobile rubber sealing ring realizes the purposes of good sealing effect, good abrasion resistance, good aging resistance and tearing prevention and is prolonged in service life.

Owner:ANHUI AOFENG AUTOMOBILE FITTINGS

Composite acid supported catalyst and catalytic synthesis method of bisphenol F

InactiveCN105536827AExcellent heat and humidity resistanceImprove insulation performanceOrganic chemistryPhysical/chemical process catalystsSynthesis methodsPhosphoric acid

The invention discloses a composite acid supported catalyst and a catalytic synthesis method of bisphenol F. A synthesis method of the composite acid supported catalyst comprises the following steps: adding phosphoric acid, diatomite, LiCl and titanium dioxide to ethanol according to a certain ratio, and refluxing and stirring above raw materials overnight (for 12-24h); and recovering ethanol after the above reaction ends, washing the obtained material with water 3 times, and carrying out vacuum drying for 12h to obtain the composite acid supported catalyst. The synthesis method of bisphenol F comprises the following steps: adding phenol and the composite acid catalyst to a reaction container, adding xylene, stirring above materials at room temperature, adding 37% of an aqueous formaldehyde solution in a dropwise manner, and heating the obtained solution to 100-150DEG C, wherein the temperatures are 100DEG C, 125DEG C and 150DEG C respectively, toluene is adopted as a solvent, and the reaction time is 2-8h; and recovering the catalyst, the solvent and phenol, and re-crystallizing the above obtained product with the recovered solvent to obtain pure bisphenol F. The catalyst has the advantages of increase of the bisphenol F yield, simple synthesis method, low cost, high catalysis activity and reusability.

Owner:JIANGNAN UNIV

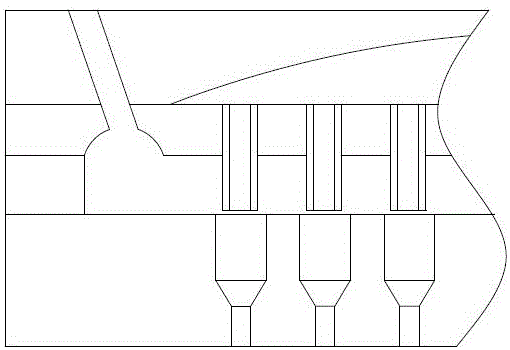

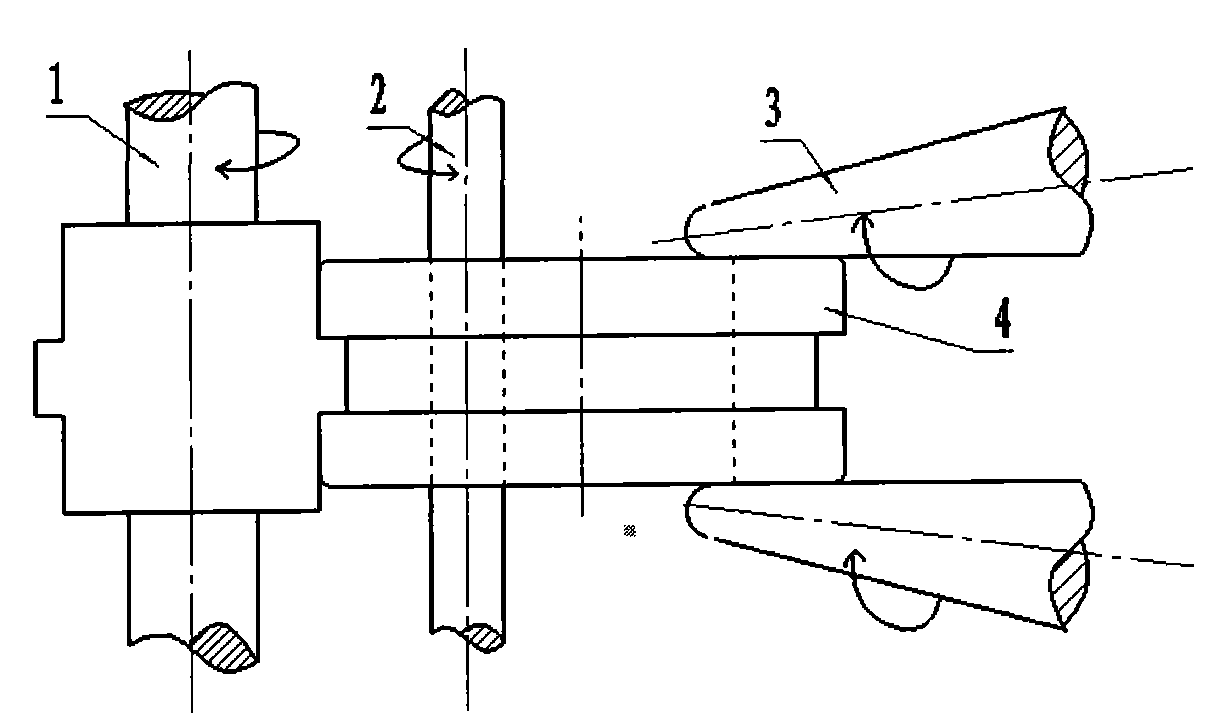

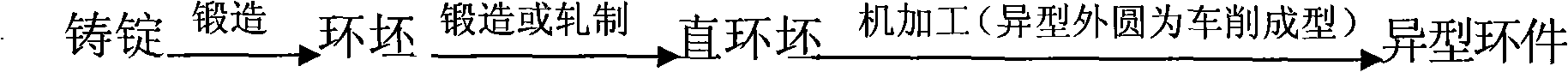

Method for preparing aero-engine casing

The invention discloses a method for preparing an aero-engine casing, which relates to a technical process for preparing the aero-engine casing by adopting a near-size thermal forming method. The method for preparing the aero-engine casing is characterized in that in a preparation process, an annular alloy blank which comprises 4.3 to 6.0 weight percent of Al, 2.0 to 3.0 weight percent of Sn, 0.2 to 0.8 weight percent of Fe and the balance of Ti and inevitable impurities is subjected to circumferential rotating deformation rolling. In the method, an alloy element Fe is added into an alloy, so cracking in thermal and cold processing is avoided effectively, and a processed window is wide; and a contour roll of which the outside cylindrical surface has a convex structure matched with the concave structure of the external wall of the aero-engine casing and a core roll are adopted to perform circumferential rotating deformation rolling, the size of the section of a formed special annular section approaches the size of the section of the finished product, the interruption of a processing line is avoided, mechanical processing amount is reduced, and expensive raw materials are saved.

Owner:BAOJI TITANIUM IND

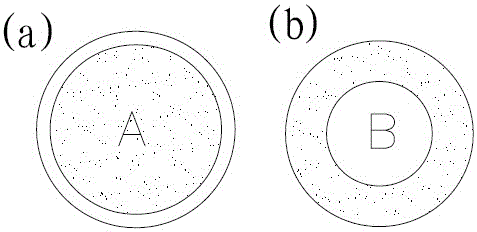

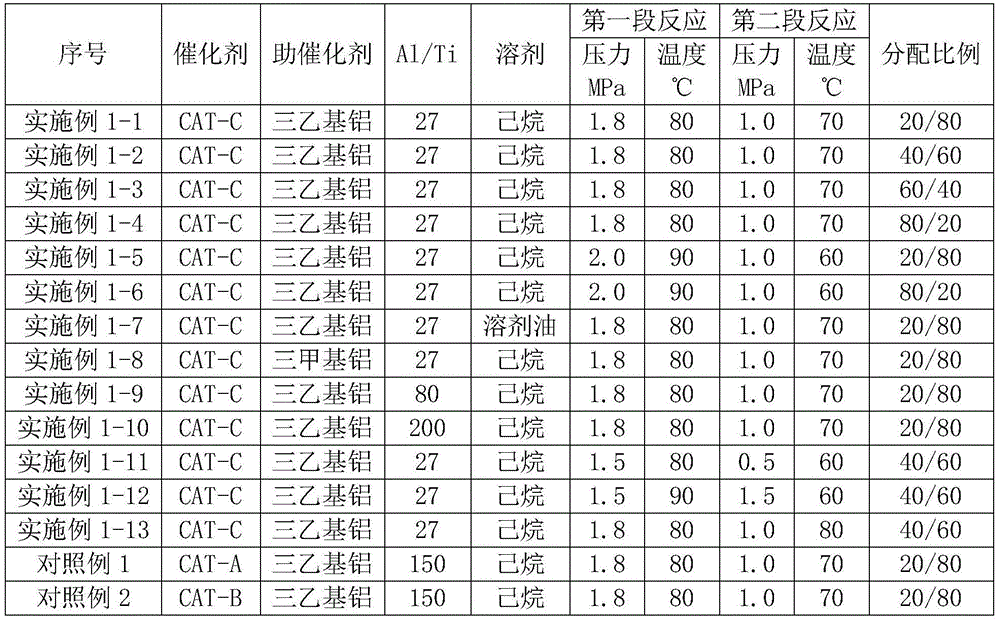

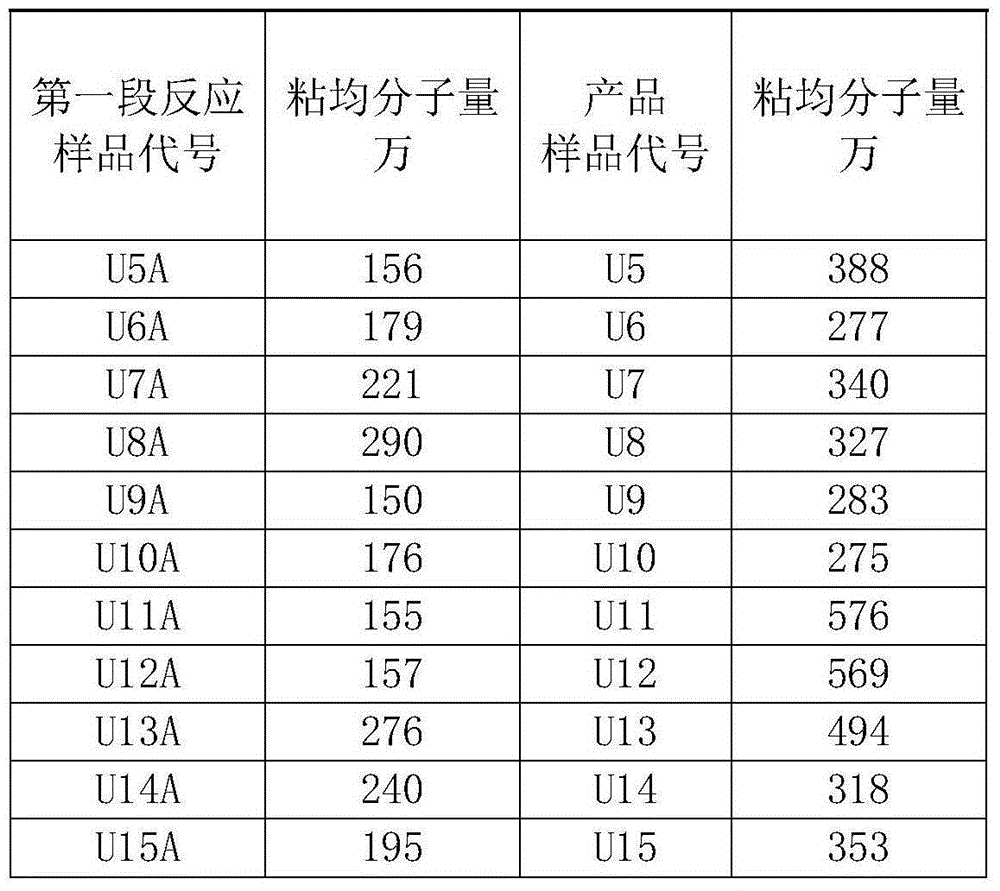

Ultrahigh molecular weight polyethylene and preparation method thereof

The invention discloses an ultrahigh molecular weight polyethylene and a preparation method thereof. The ultrahigh molecular weight polyethylene is prepared by the following steps: taking an active titanium supported catalyst as the main catalyst, organic aluminum compounds as the co-catalyst, and ethylene as the polymerization raw material, and carrying out two-stage polymerization reactions in an alkane solvent; wherein the viscosity average molecular weight of the polymerization products of the first stage is 800,000 to 2,200,000, and the viscosity average molecular weight of the polymerization products of the second stage is 2,000,000 to 4,200,000. The prepared ultrahigh molecular weight polyethylene is applied to pipe extrusion and has the following advantages: (1) processing performance is better, compared with commercial polyethylene, the pressure on the die head of an extruding machine is lower, the extrusion current is smaller, and the provided polyethylene can be used to produce pipes with a larger diameter; (2) the smoothness of the external surface of prepared ultrahigh molecular weight polyethylene pipes is prominently better than that of commercial resin; and (3) the production efficiency and yield rate of extruded pipes are both improved by using the ultrahigh molecular weight polyethylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

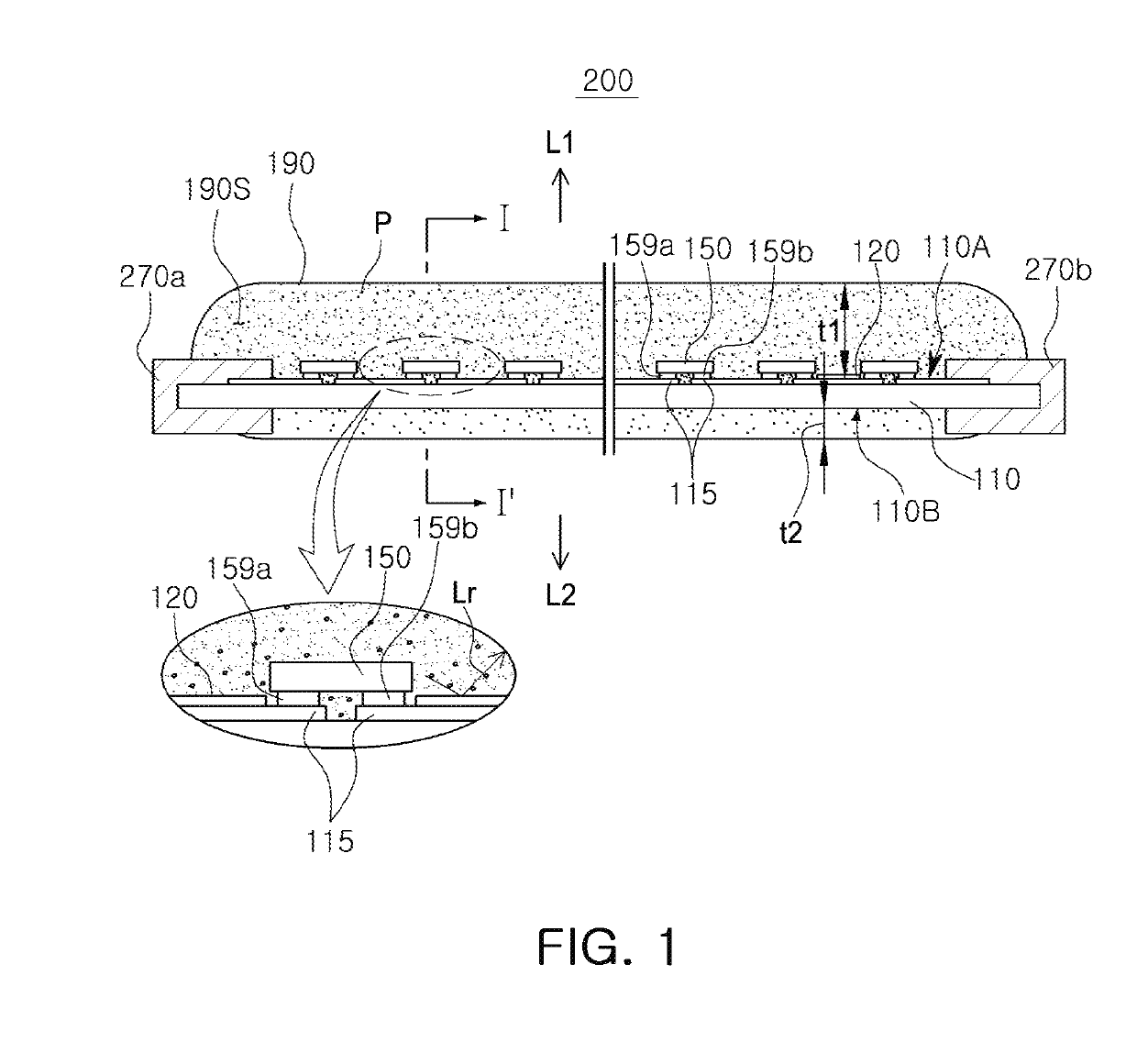

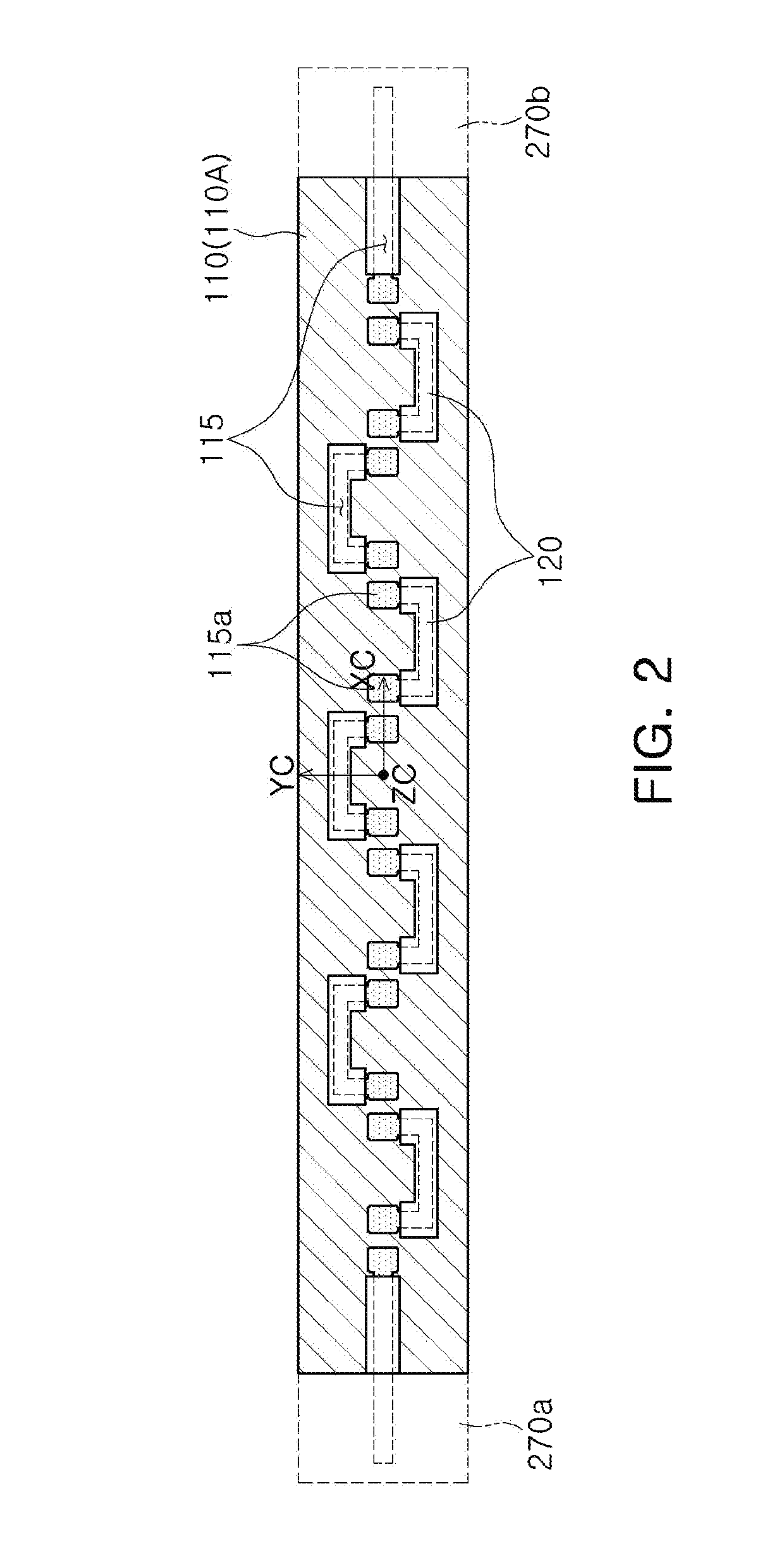

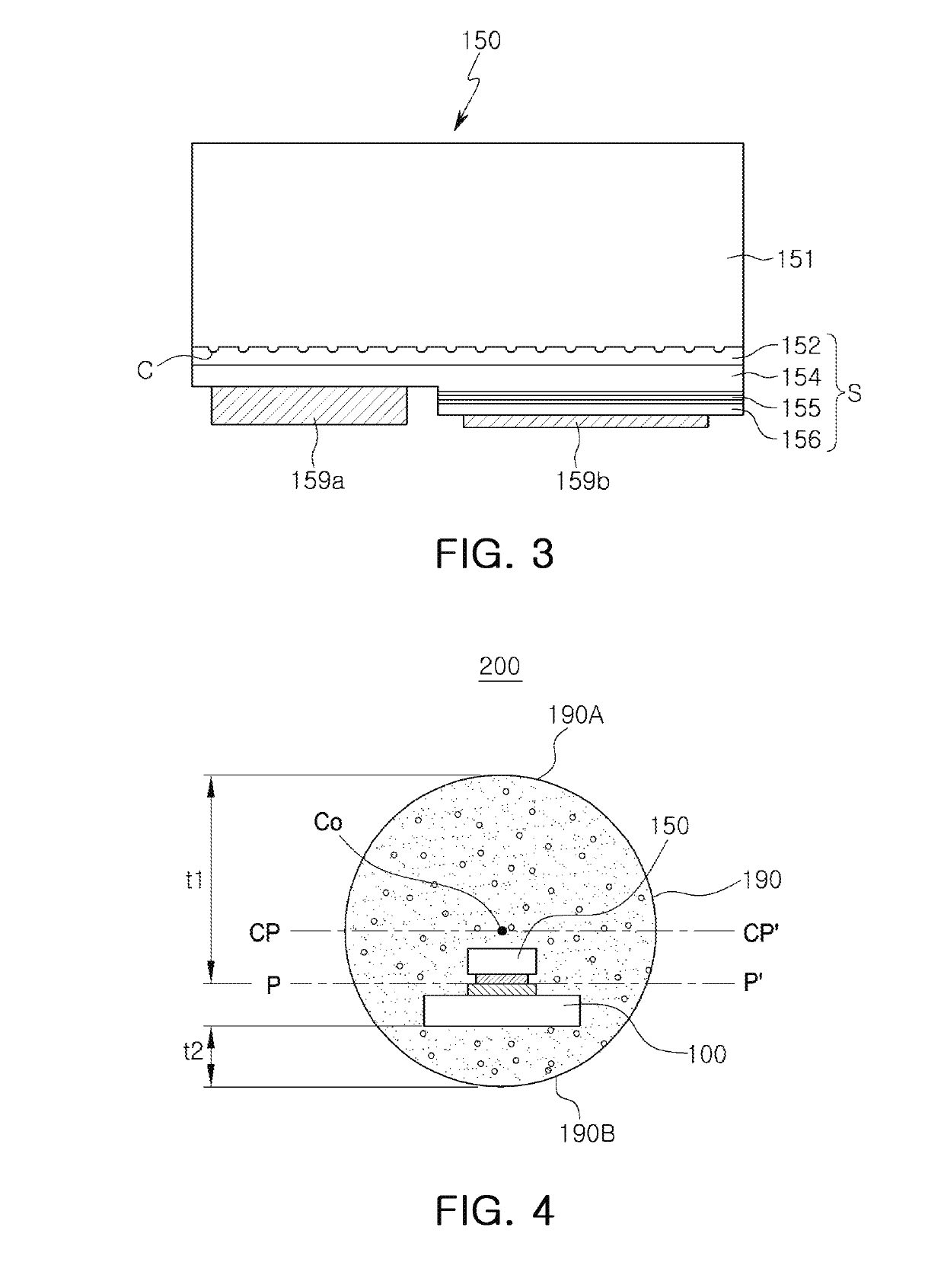

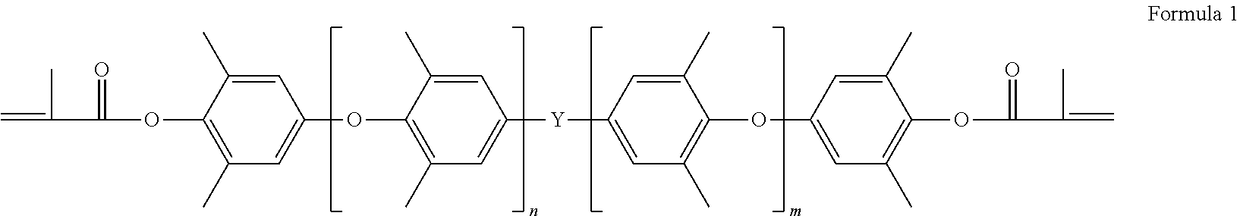

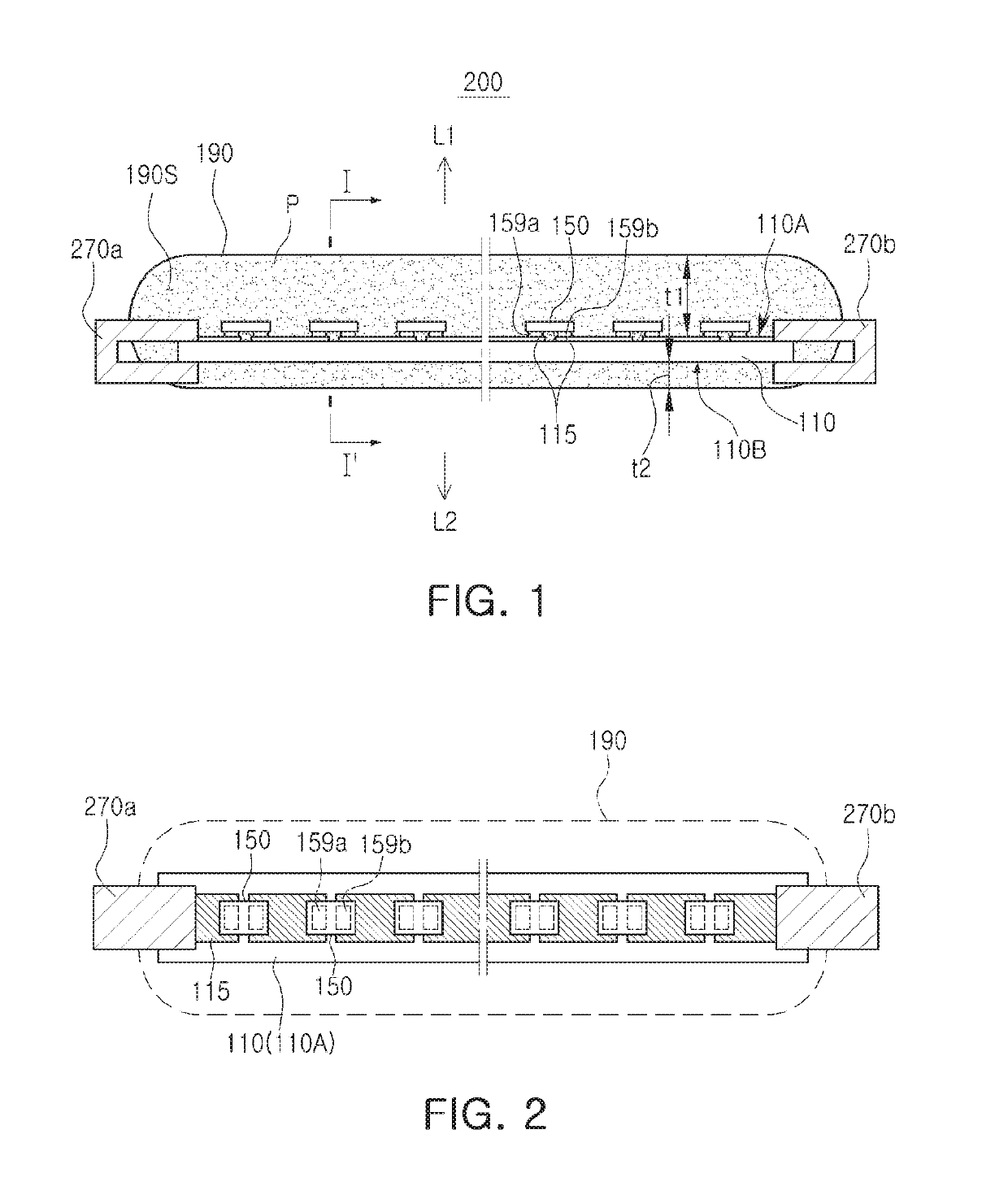

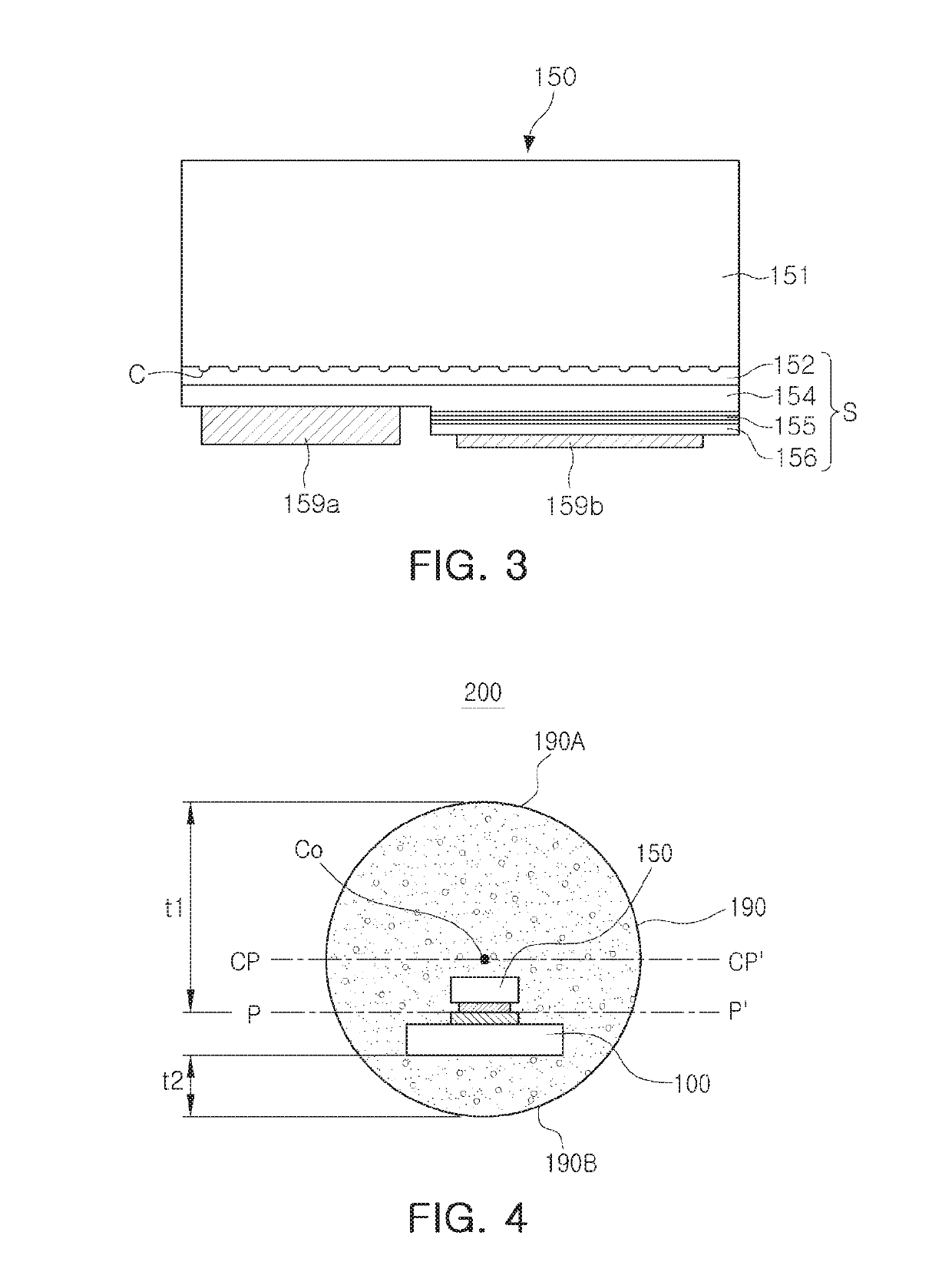

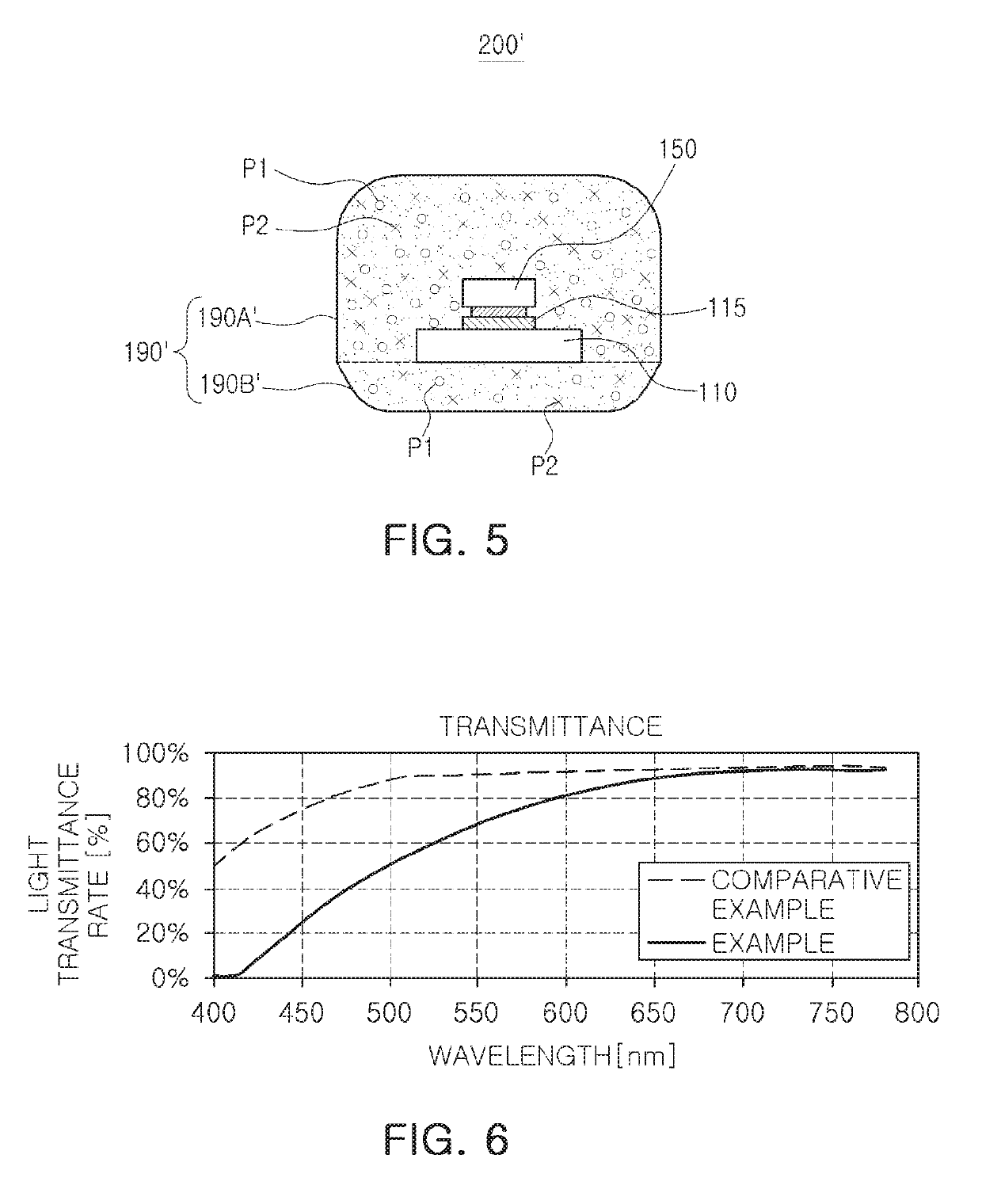

LED module and LED lamp including the same

ActiveUS20190326480A1Excellent processabilityImprove luminanceElectroluminescent light sourcesSolid-state devicesEngineeringWavelength conversion

A light emitting diode (LED) module includes: a flexible substrate having a first surface on which a circuit pattern is disposed, and a second surface opposite the first surface; a plurality of light emitting diode (LED) chips mounted on the first surface of the flexible substrate, and electrically connected to the circuit pattern; an insulating reflective layer disposed on the first surface of the flexible substrate, and covering a portion of the circuit pattern; first and second connection terminals disposed at both ends of the flexible substrate, and connected to the circuit pattern; and a wavelength conversion layer covering the plurality of LED chips and surrounding the flexible substrate in a cross-sectional view.

Owner:SAMSUNG ELECTRONICS CO LTD

Thermosetting resin composition for frequency, and prepreg, laminated sheet and printed circuit board using same

ActiveUS20170342264A1Excellent processabilityLow thermal expansion characteristicSynthetic resin layered productsPrinted circuit aspectsDielectric lossChemistry

Owner:DOOSAN CORP

Tire Bead Fiber

ActiveUS20180134098A1Increase air volumeExcellent processabilityBicycle tyresTyre beadsPolyesterElastic modulus

Provided is bead fiber with which sufficient air volume can be infused for making a high-performance bicycle tire, which has superior workability that does not require drying of the bead fibers when covering the bead fibers with rubber, and which is effective in preventing rim detachment. A high-performance bicycle tire can be obtained by using this tire bead fiber. The tire bead fiber is characterized by being formed using wholly aromatic polyester fiber with a modulus of elasticity of 800 cN / dt or greater.

Owner:KB SEIREN LTD

Block copolymer, rubber composition containing the same and molded product

InactiveUS20060106150A1Excellent processabilityUniform molecular weightSpecial tyresUnsaturated bondsAging resistance

An objective of the present invention is to provide a block copolymer which is excellent in processability at the time of preparing a rubber composition and leads to a cross-linked rubber composition excellent in tensile property, wearing resistance, weatherability, ozone resistance and heat aging resistance when it is cross-linked, a rubber composition containing the block copolymer and a molded product. The block copolymer of the present invention comprises two polymer blocks each having an ethylenic unsaturated bond and other polymer block which is interposed between two polymer blocks, has a uniform weight average molecular weight in the range from 5,000 to 100,000. The weight average molecular weight of the polymer block having the ethylenic unsaturated bond is preferably in the range from 1,000 to 20,000.

Owner:JSR CORPORATIOON

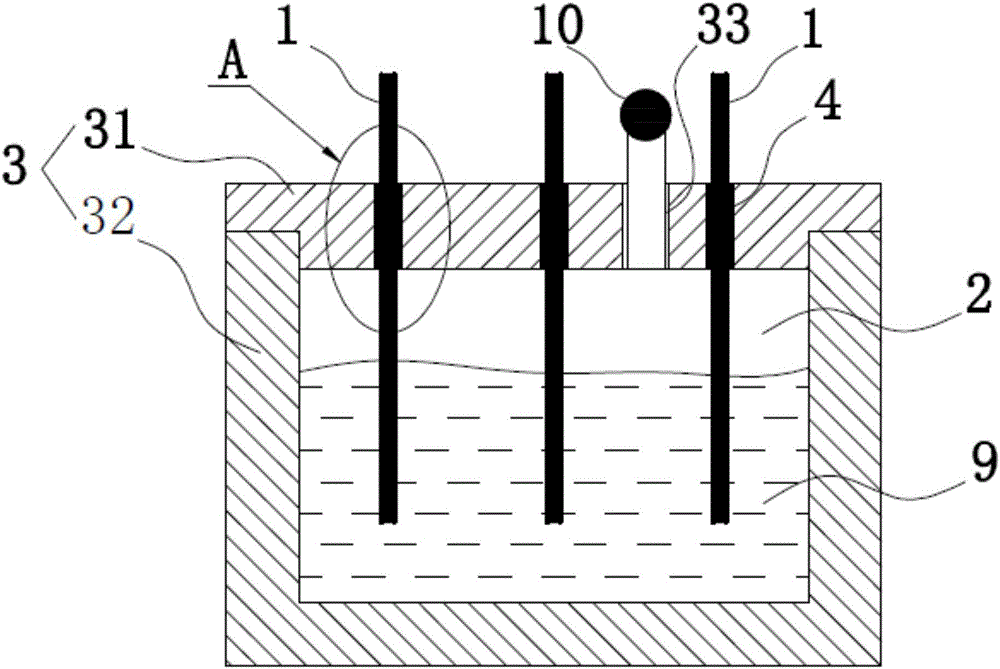

Tilt angle sensor

InactiveCN106123861AExcellent surface performanceExcellent processabilityIncline measurementUltimate tensile strengthElectrolyte

The invention provides a tilt angle sensor and belongs to the technical field of sensors. The tilt angle sensor comprises an electrode and a shell with a cavity structure, wherein an electrolyte is injected into the cavity; an electrode hole running through the shell is formed in the shell; an electrode is inserted into the electrode hole; one end of the electrode is inserted deep into the cavity while the other end of the electrode is located in the shell; a ceramic material is taken as the material of the shell. According to the invention, the shell is made from the ceramic material, the strength of the shell made from the ceramic material is higher, pressing injection molding can be applied and the design and processing of the tilt angle sensor are more convenient. Besides, the surface property and the processing property of the shell made from the ceramic material are greatly better than those of the shell made from glass material, so that the tilt angle sensor with more excellent performance, higher reliability, diverse structure and wider application scope can be manufactured.

Owner:苏州理欧电子科技有限公司

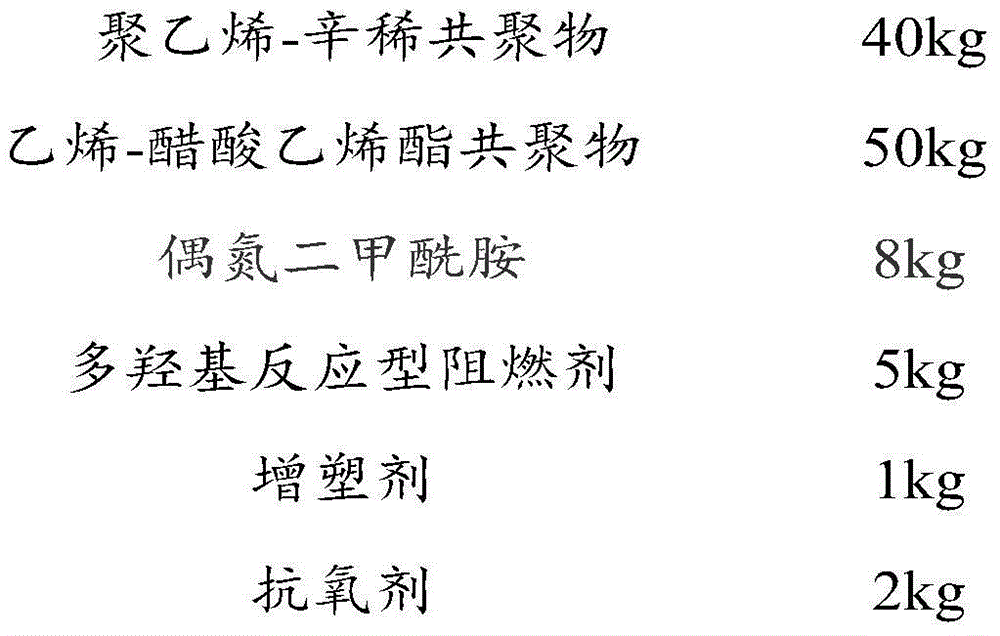

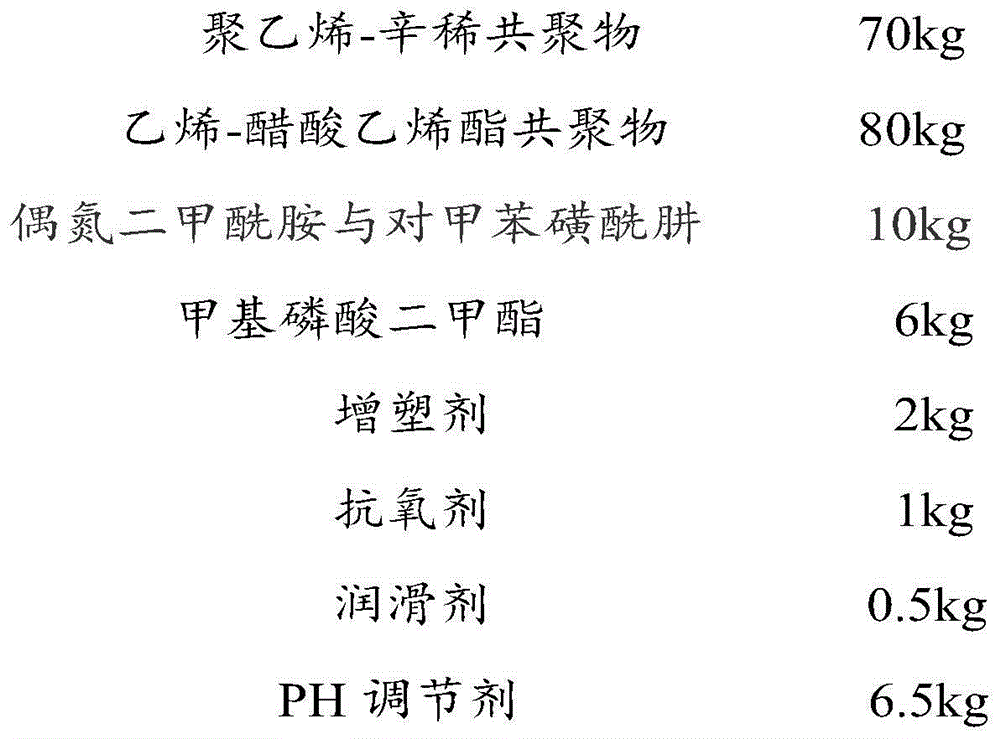

Composite filling material, preparing method thereof and application thereof

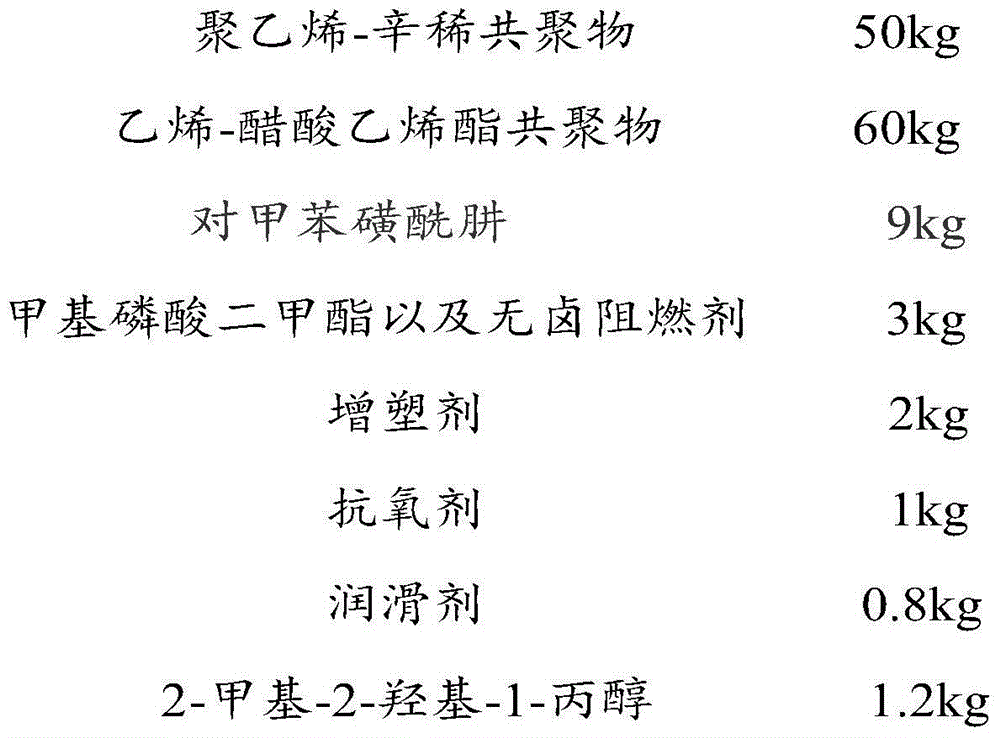

The invention provides a composite filling material, a preparing method thereof and an application thereof. The composite filling material mainly comprises, by mass, 40 parts to 70 parts of polyethylene-octylene copolymers, 50 parts to 80 parts of ethylene-vinyl acetate copolymers, 8 parts to 10 parts of foaming agents, 2 parts to 6 parts of fire retardants and 3 parts to 10 parts of processing agents. The preparing method includes the steps that A, the polyethylene-octylene copolymers, the ethylene-vinyl acetate copolymers and the foaming agents are evenly mixed and stirred and extruded through an extruder; B, in the extruding process, the fire retardants and the processing agents are added, then the mixture is extruded into a mold for vacuum shaping, and finally cooling is carried out to obtain the product. The composite filling material serves as fillers in a cushion, a mattress and a pillow to be applied. The composite filling material has the advantages that aging is not prone to occurrence, the air retaining performance is good, the affinity and the soft performance are good, and deformation is not prone to occurrence after long time use.

Owner:费珏璐

Laminate film

InactiveUS20050202266A1Excellent processabilityEasy to processLiquid surface applicatorsSynthetic resin layered productsDouble bondSide chain

A laminate film has a clear layer (B) comprising an acrylic-based polymer (B1) having at least one longer unsaturated double bond group and at least one shorter unsaturated double bond group as side chains, and having a weight-average molecular weight not less than 50,000 but not more than 500,000, the longer unsaturated double bond group introduced in the acrylic-based polymer (B1) by a long-chain unsaturated carboxylic acid having a molecular weight of 150 or more, and the shorter unsaturated double bond group introduced in the acrylic-based polymer (B1) by a short-chain unsaturated carboxylic acid having a molecular weight of less than 150. Compared with laminate films prepared by spray coating, dip coating, or other coating methods, this laminate film is excellent in processability, coating film properties, and ornamental properties. Thus, an article can be excellently decorated with the laminate film provided by the present invention.

Owner:HITACHI CHEM CO LTD +1

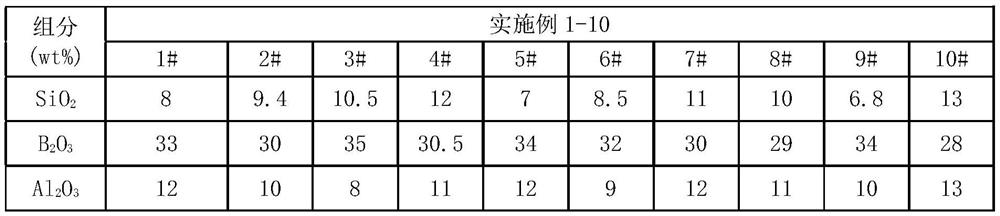

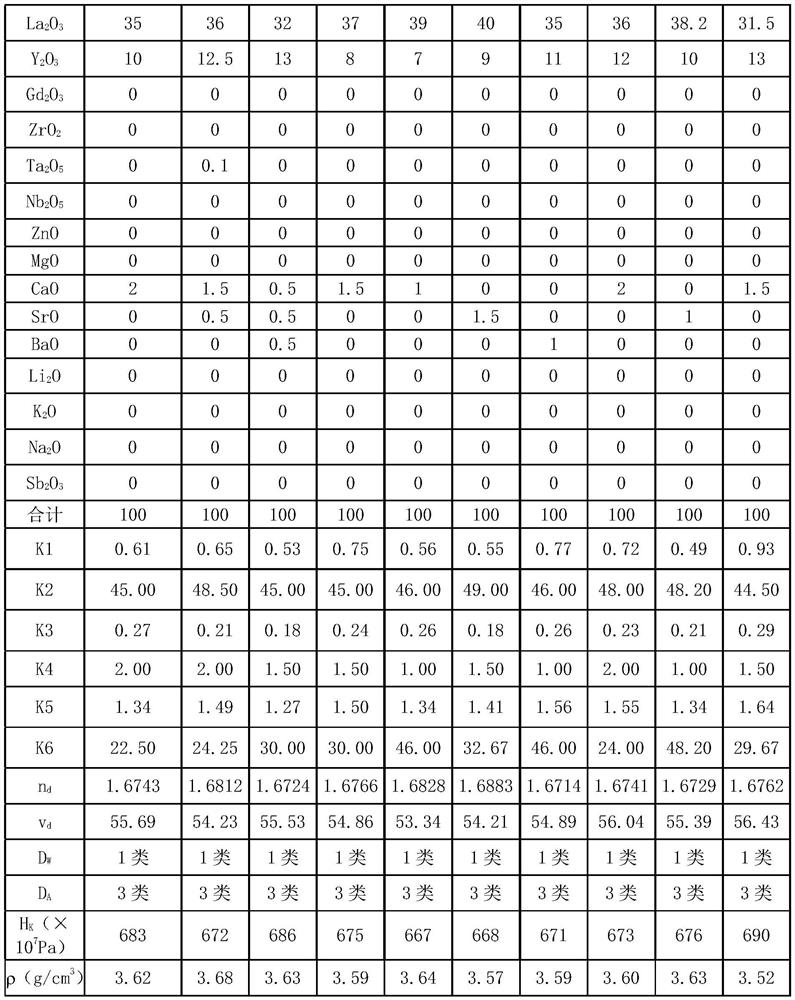

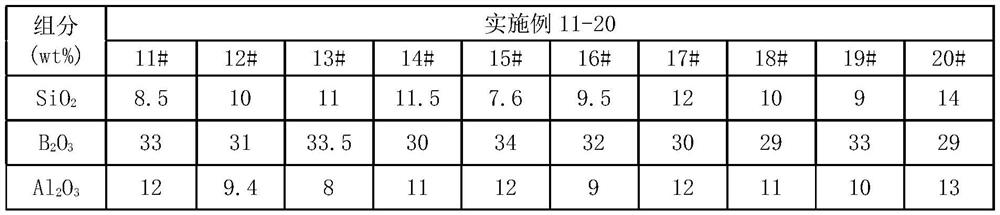

Optical glass, glass preform, optical element and optical instrument

PendingCN113415990AExcellent processabilityExcellent durabilityOptical elementsSurveillance cameraRefractive index

The invention provides optical glass. The optical glass comprises the following components in percentage by weight: 2-25% of SiO2, 12-40% of B2O3, 2-20% of Al2O3, 30-65% of Ln2O3 and 0-15% of RO. The refractive index nd of the optical glass is more than 1.66, the ratio of (SiO2+Al2O3+Ln2O3) to (RO+B2O3+nd x 8) is 0.6-3.0, the Ln2O3 is the total content of La2O3, Y2O3 and Gd2O3, and the RO is the total content of MgO, CaO, SrO and BaO. The refractive index of the obtained optical glass is more than 1.66, the Abbe number is more than 50, the machinability and chemical durability are obviously superior to that of the prior art, the transmittance is not obviously reduced after long-term use, and the optical glass is very suitable for outdoor monitoring cameras and vehicle-mounted lenses, and is particularly suitable for being applied to imaging applications needing to bear severe working environments.

Owner:CDGM OPTICAL GLASS

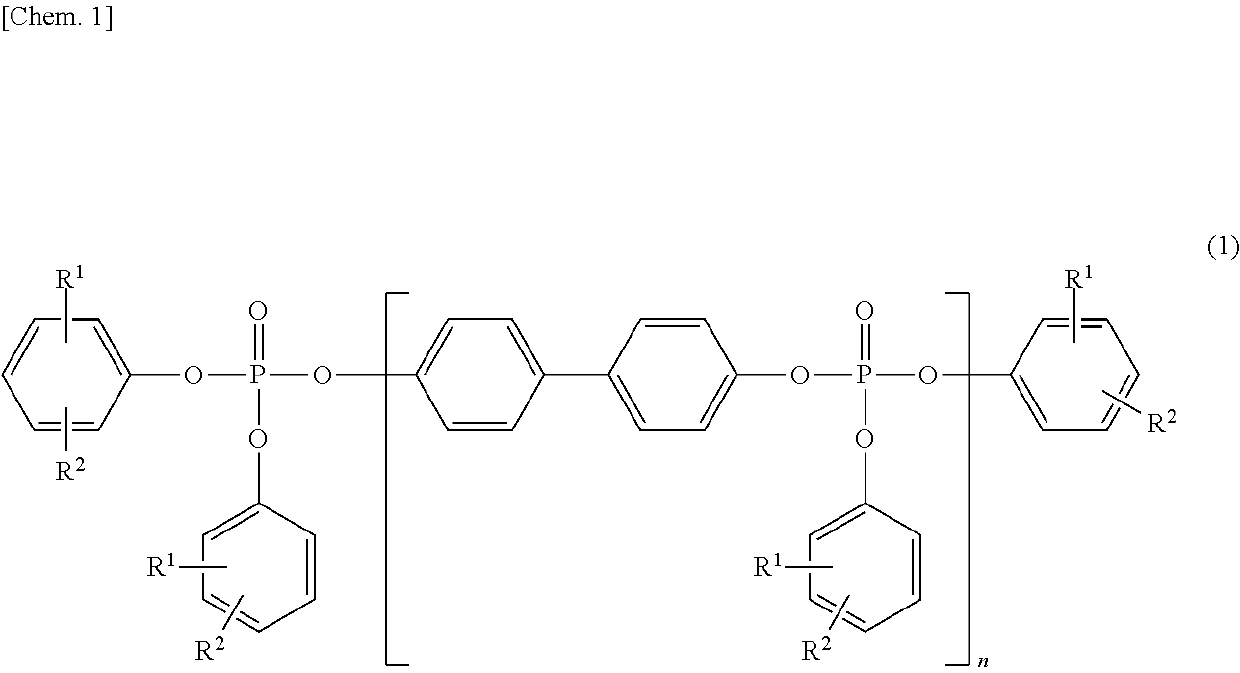

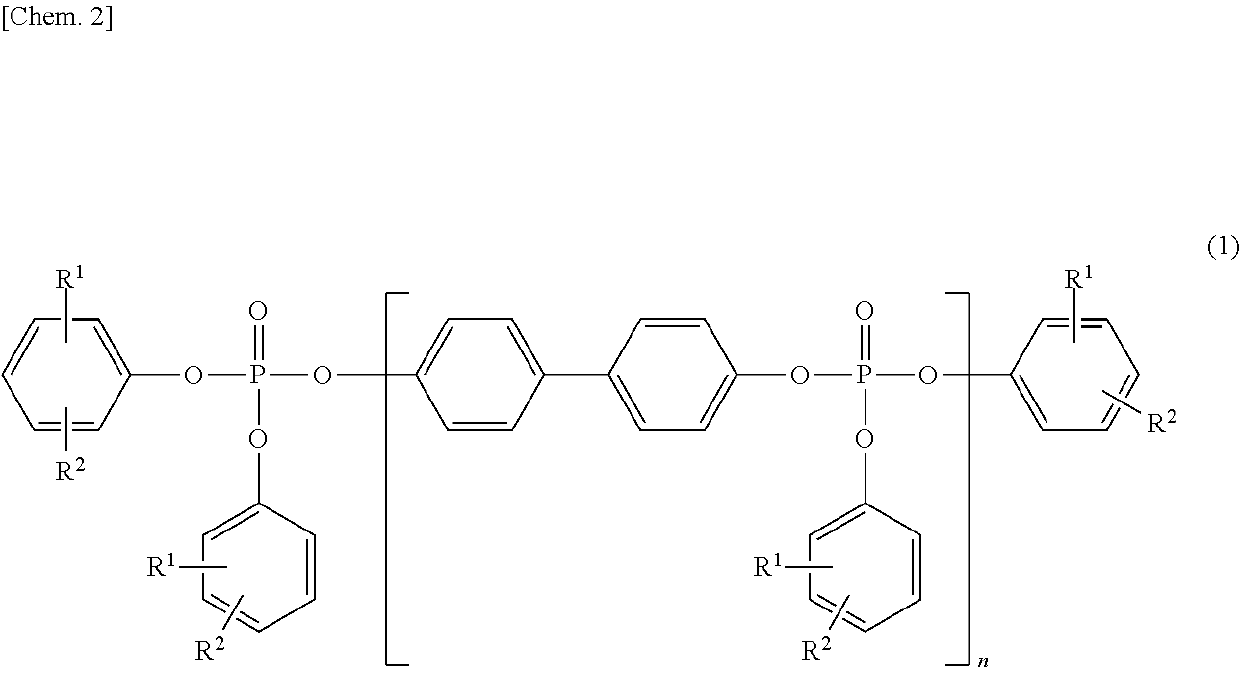

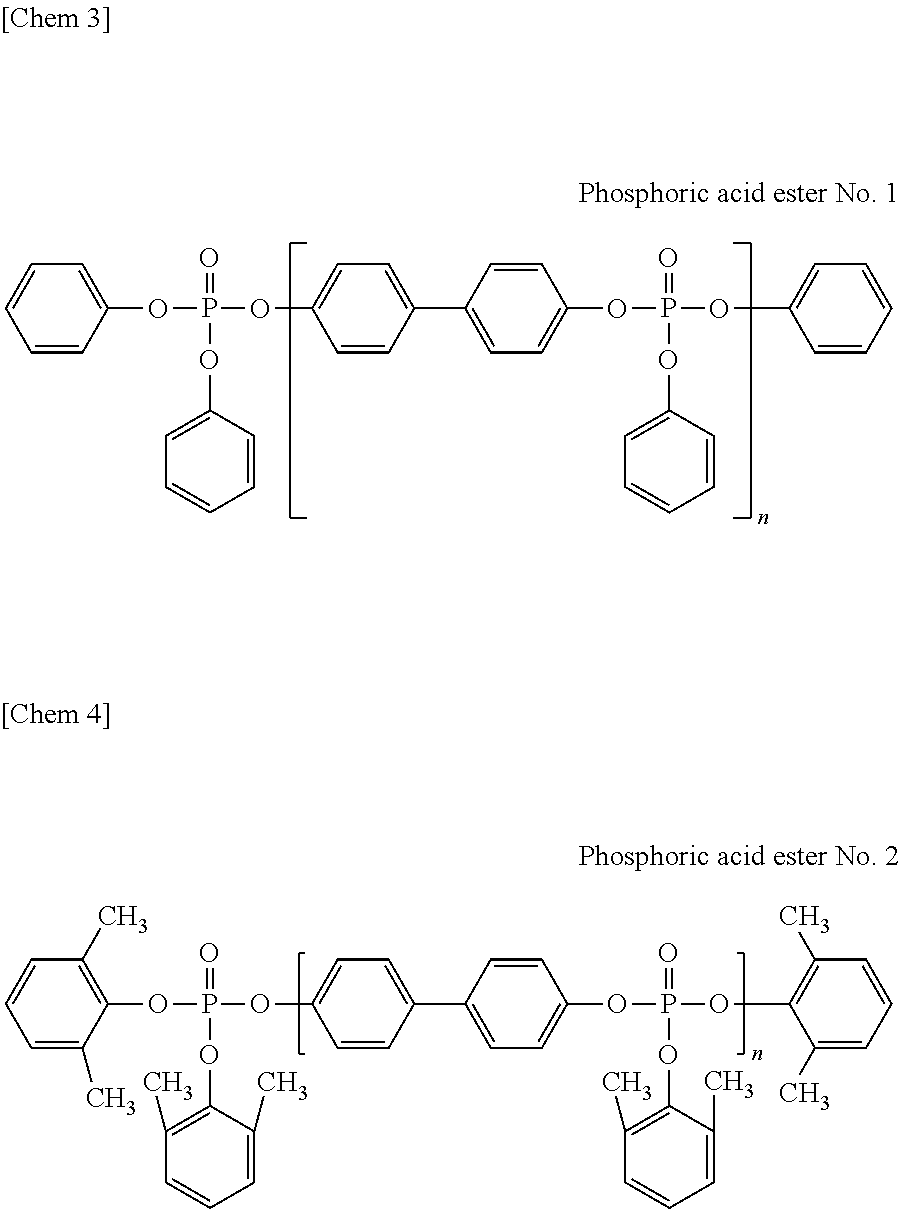

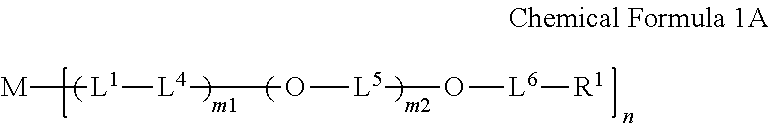

Flame retardant composition, flame retardant resin composition containing said flame retardant composition, and molded body of said flame retardant resin composition

InactiveUS20200277316A1Excellent stabilityExcellent processabilityGroup 5/15 element organic compoundsComposite materialPhosphate

Provided is a flame retardant composition containing at least one phosphate ester represented by general formula (1), wherein the total content of phosphate esters in which n=1, 2, 3, 4, or 5 among the phosphate esters is 99-100 mass %, and the content of phosphate esters represented by general formula (1) in which n=1 is at least 60 mass % and less than 70 mass % with respect to the total amount of the phosphate esters (in formula (1), R1 and R2 each independently represent a hydrogen atom or a methyl group, and n represents a number of 1, 2, 3, 4, 5, 6 or 7).

Owner:ADEKA CORP

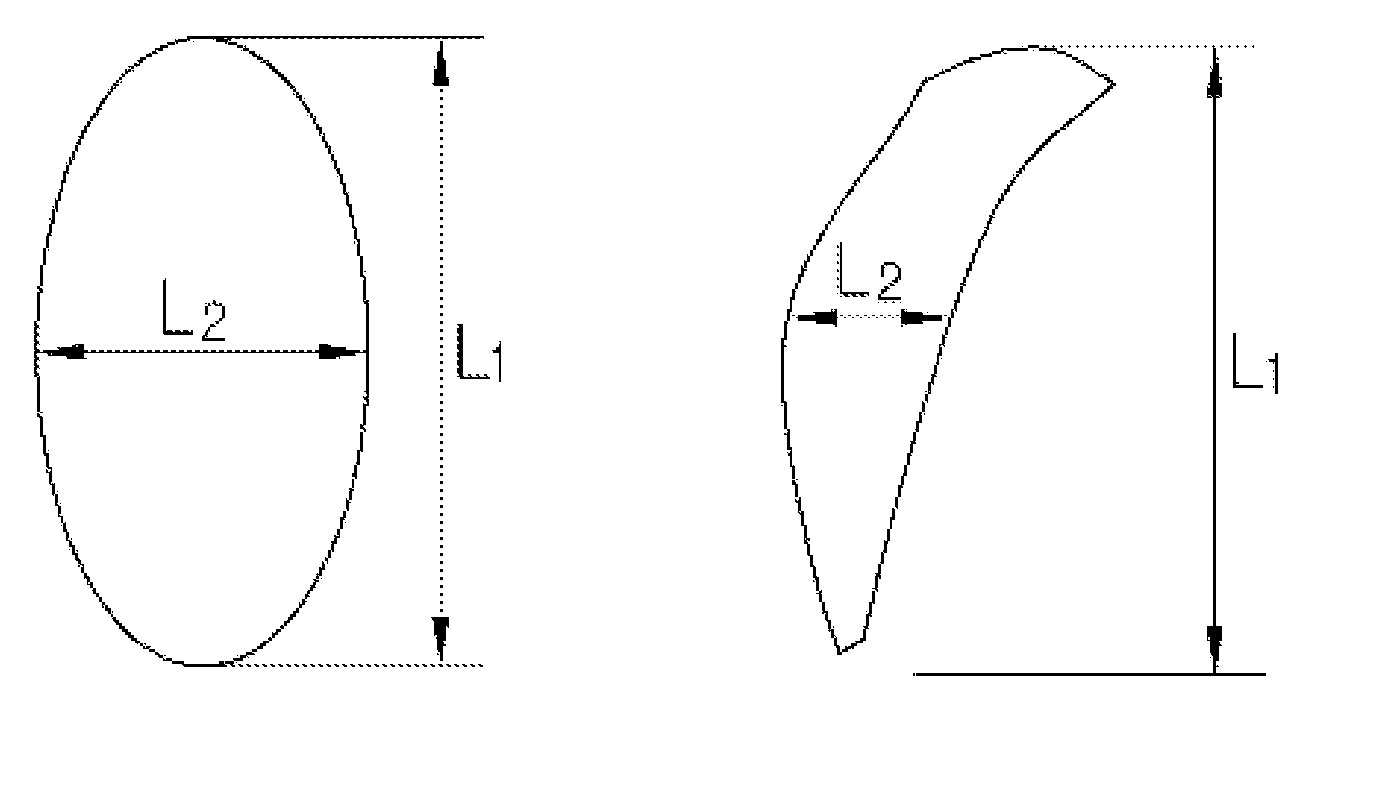

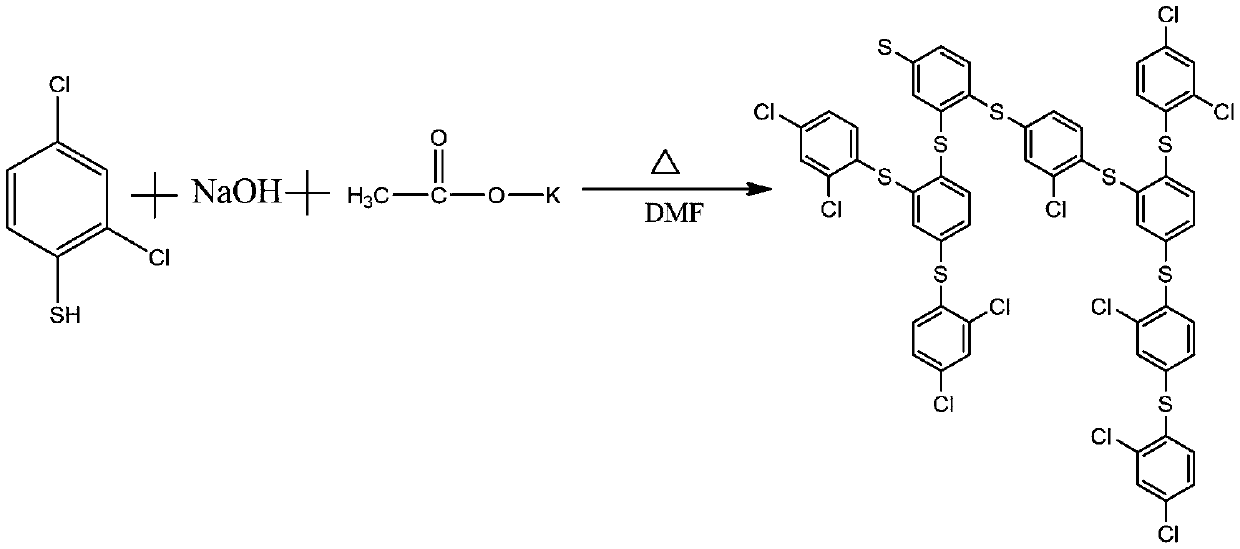

Amorphous artificial marble chip and manufacturing method thereof

ActiveUS20150166761A1Improved strength , durability and water tightnessExcellent processabilityMaterials science

Owner:SCHEM

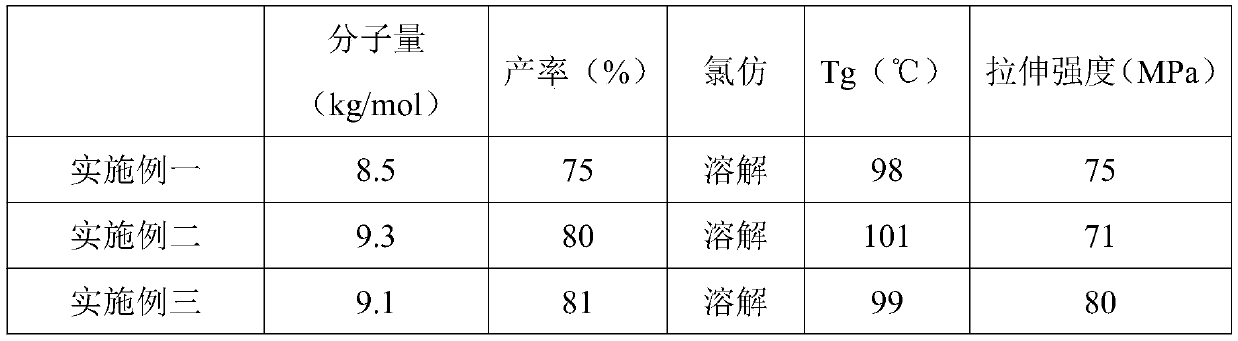

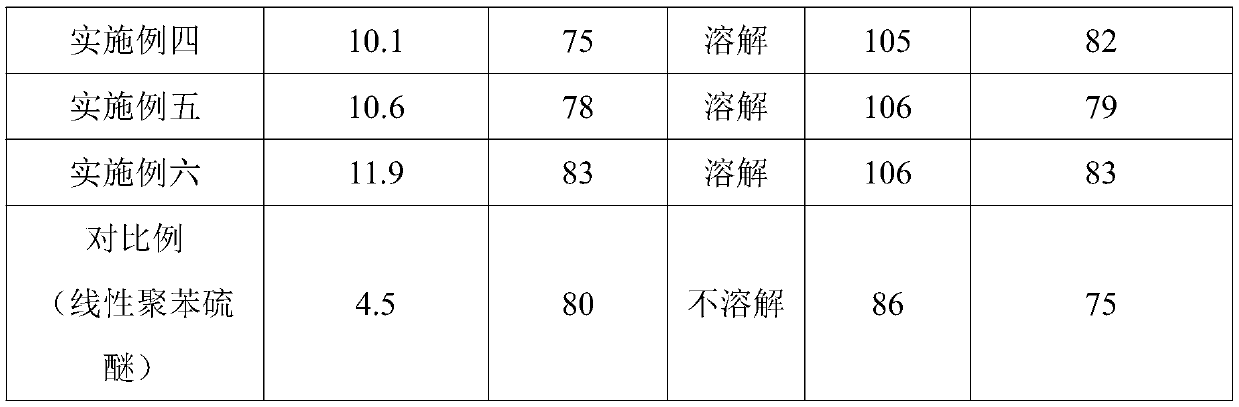

Preparation method of hyperbranched polyphenylene sulfide

The invention belongs to the field of high polymer materials, and particularly discloses a preparation method of hyperbranched polyphenylene sulfide. The preparation method comprises the following steps: (1) adding 2,4-dichlorothiophenol, sodium hydroxide and potassium acetate into an N,N-dimethylformamide solvent, and carrying out oil bath heating under the protection of high-purity nitrogen; (2) increasing the temperature of the system to 255-275 DEG C, and carrying out constant-temperature treatment on the system for 150-210 minutes; (3) cooling the system to 80-90 DEG C, adding distilled water, and continuously stirring the system for 30-60 minutes; (4) adding the system into a hydrochloric acid solution, and continuously stirring the system for 180-240 minutes; (5) filtering the system, and adding a filtered-out substance into an acetone solution for elution; (6) filtering the system after elution, and adding a filtered-out substance into distilled water for elution; and (7) filtering the system after elution, and drying a filtered-out substance to obtain the hyperbranched polyphenylene sulfide powder product. The preparation method is low in raw material price, simple in reaction process and short in reaction time, the synthesis process is easy to control, the reaction yield is high, and the rate of unqualified products is greatly reduced.

Owner:YIBIN TIANYUAN GRP CO LTD

LED module and LED lamp including the same

InactiveUS20190293242A1High level of illuminationExcellent processabilitySemiconductor/solid-state device detailsElectric circuit arrangementsOptical transmittanceEngineering

An LED module includes a flexible substrate having a first surface on which a circuit pattern is disposed and a second surface opposing the first surface, and having a light transmittance of 80% or more; a plurality of LED chips mounted on the first surface of the flexible substrate, and electrically connected to the circuit pattern; first and second connection terminals disposed at both ends of the flexible substrate, and connected to the circuit pattern; and a wavelength converter covering the plurality of LED chips, and surrounding the flexible substrate.

Owner:SAMSUNG ELECTRONICS CO LTD

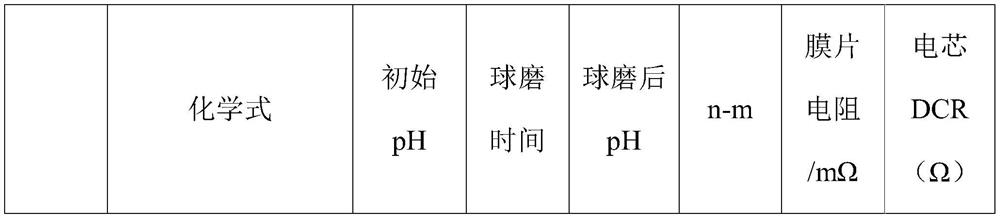

Positive electrode material as well as stability judgment method and application thereof

PendingCN114284488AExcellent processabilityExcellent electrochemical performanceCell electrodesSecondary cellsElectrical resistance and conductanceElectrical battery

The invention provides a positive electrode material as well as a stability judgment method and application thereof. The positive electrode material is of an alpha-NaFeO2 structure, the pH value of the positive electrode material before ball milling is m, the pH value of the positive electrode material after ball milling is n, n-m is smaller than or equal to 0.15, and the positive electrode material is a nickel-cobalt-manganese or nickel-cobalt-aluminum ternary material and can be doped and coated. According to the positive electrode material provided by the invention, the pH value difference is within a certain range before and after ball milling, the stability is good, and the material has relatively excellent machinability and electrochemical performance. According to the positive electrode material provided by the invention, local gelling caused by dispersion processes such as stirring in a slurry preparation process in a positive electrode slurry preparation process is avoided, a prepared positive electrode plate has lower diaphragm resistance, and a prepared battery also has lower direct current impedance. The method for judging the stability of the positive electrode material is high in accuracy, and the finally obtained result is extremely matched with the stability matching degree of the positive electrode material.

Owner:SHANGHAI RUIPU ENERGY CO LTD

Metal/fiber-reinforced resin material composite body, method for producing same and bonding sheet

PendingUS20210129488A1Excellent processabilityProduction cost be excellentSynthetic resin layered productsLaminationPolymer chemistryFibre reinforcement

This metal-FRP composite body comprises a metal member, an FRP layer and a bonding resin layer that is interposed between the metal member and the FRP layer. The bonding resin layer is a solidified product of a phenoxy resin (A) by itself, or alternatively, a cured product of a bonding resin composition that contains 50 parts by weight or more of the phenoxy resin (A) in 100 parts by weight of the resin components; and the bonding resin layer firmly bonds the metal member and the FRP layer to each other. The bonding resin composition may additionally contain 5-85 parts by weight of an epoxy resin (B) relative to 100 parts by weight of the phenoxy resin (A), and a crosslinking agent (C) that contains an acid dianhydride.

Owner:NIPPON MICROMETAL

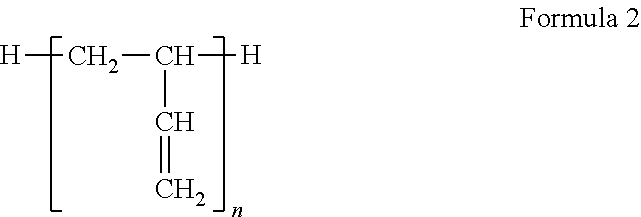

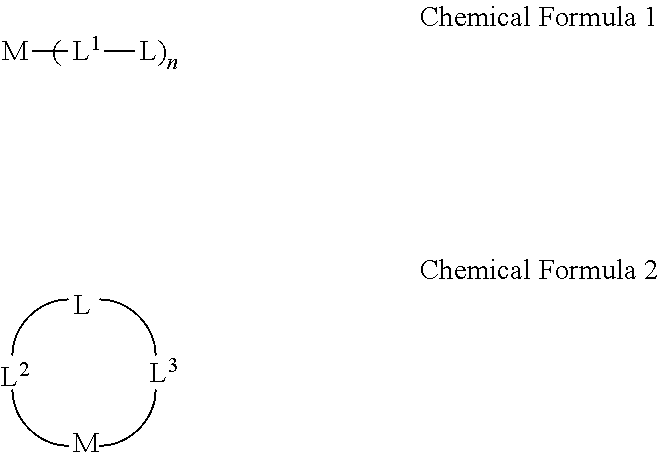

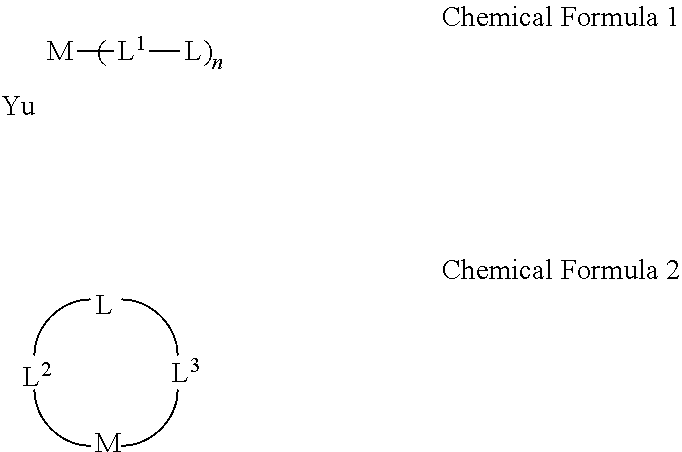

Quantum dot, curable composition comprising the same, cured layer using the composition and color filter including the cured layer

PendingUS20210108135A1Improve passivation effectImprove lighting efficiencyMaterial nanotechnologyOptical filtersQuantum dotMaterials science

Quantum dots surface-modified with a compound represented by Chemical Formula 1 or Chemical Formula 2, a curable composition including the quantum dots, a cured layer, and a color filter.In Chemical Formula 1 and Chemical Formula 2, each substituent is the same as defined in the specification.

Owner:SAMSUNG SDI CO LTD

Rubber composition for tire and pneumatic tire

The present invention provides: a rubber composition for tires which has excellent processability and has excellent low heat build-up when formed into a tire; and a pneumatic tire using the same. The rubber composition for tires of the present invention is a rubber composition for tires, the rubber composition containing a diene rubber (A) and a microparticle (B), a vinyl group content of the diene rubber (A) being from 5 to 35 mass %, the microparticle (B) being a mercapto group-containing organic microparticle in which a crosslinkable oligomer or polymer (b1) is crosslinked, an average particle size of the microparticle (B) being from 1 to 200 μm, and a content of the microparticle (B) being from 1 to 55 parts by mass per 100 parts by mass of the diene rubber (A).

Owner:YOKOHAMA RUBBER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com