Ultrahigh molecular weight polyethylene and preparation method thereof

An ultra-high molecular weight polyethylene technology, applied in the field of ultra-high molecular weight polyethylene preparation, can solve the problems of low processing efficiency, low extrusion speed, and difficulty in extrusion of ultra-high molecular weight polyethylene, and achieves low die pressure, The effect of small extrusion current, improving production efficiency and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

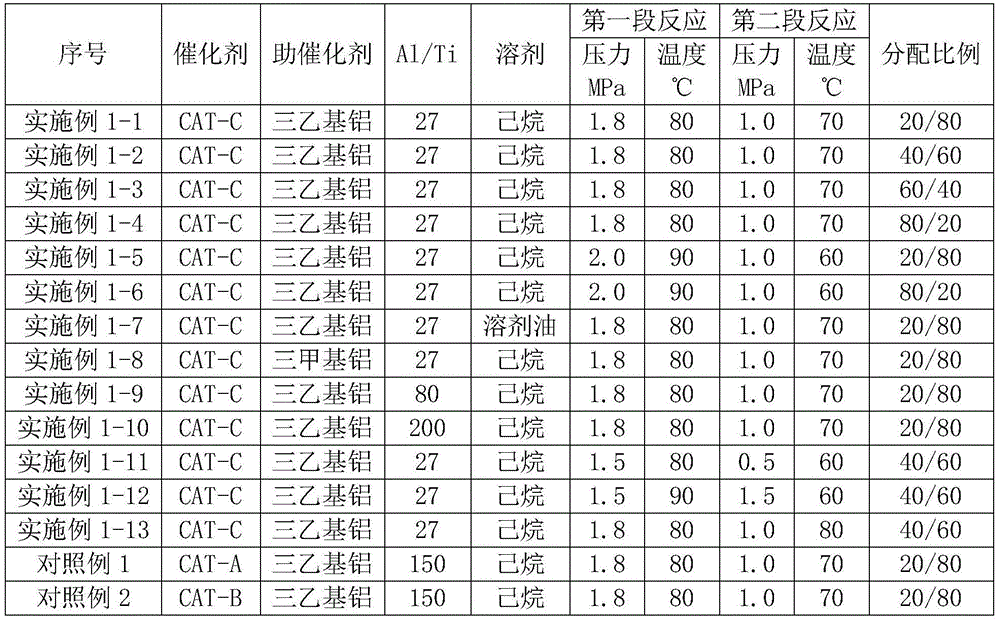

Embodiment 1

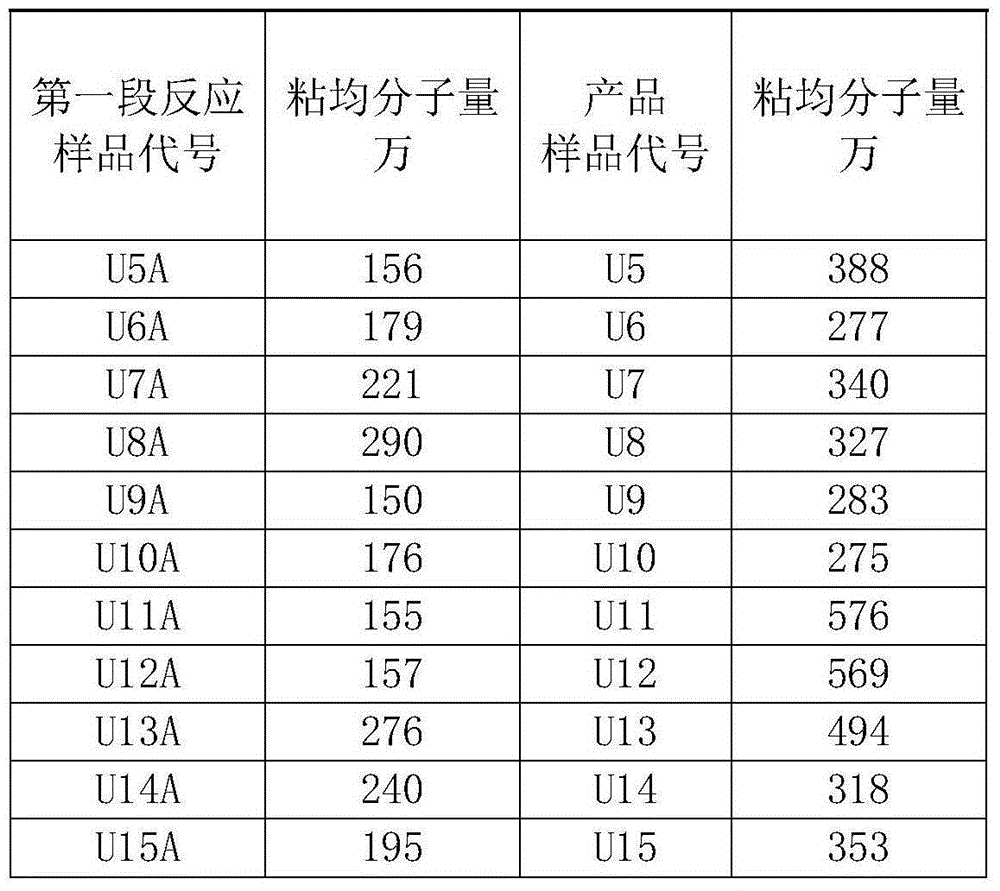

[0037] Add 200 liters of hexane solvent into the 300-liter reactor, start stirring, and set the stirring speed at 240 rpm. Then add co-catalyst triethylaluminum (hexane solvent, concentration: 0.88 mol / L) and 1.0 g catalyst CAT-C respectively in sequence, and the ratio of Al to Ti is 27. Heat the material in the reactor to T1=80°C by external circulating water, and then continuously feed ethylene to maintain the total pressure of the reactor P1=1.8MPa (ie polymerization pressure) to carry out slurry polymerization.

[0038] Polymerize for a certain period of time, when 4Kg is absorbed by ethylene (promptly obtain product output about Y1=4Kg), stop the first stage reaction, take a sample and test the polymer viscosity-average molecular weight, and the sample is marked as U1A.

[0039] Exhaust the excess gas, reduce the reaction pressure to P2=1.0MPa, and at the same time reduce the temperature of the material in the reactor to T2=70°C through the external circulating water, mai...

Embodiment 2

[0042] The basic process is the same as in Example 1-1, but with the following changes:

[0043] Y1 is 8Kg, Y2 is 12Kg, like this, Y1 / Y2=40 / 60.

[0044] Products obtained in Stage 2 are labeled U2A and U2, respectively.

Embodiment 3

[0046] The basic process is the same as in Example 1-1, but with the following changes:

[0047] Y1 is 12Kg, Y2 is 8Kg, like this, Y1 / Y2=60 / 40.

[0048] Products obtained in Stage 2 are labeled U3A and U3, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com