Positive electrode material as well as stability judgment method and application thereof

A technology of positive electrode material and determination method, applied in the direction of analyzing materials, battery electrodes, using mechanical devices, etc., can solve the problems of material damage, material degradation performance, coating thickness, etc., and achieve excellent processability and electrochemical performance. , The stability matching degree is consistent, and the stability is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

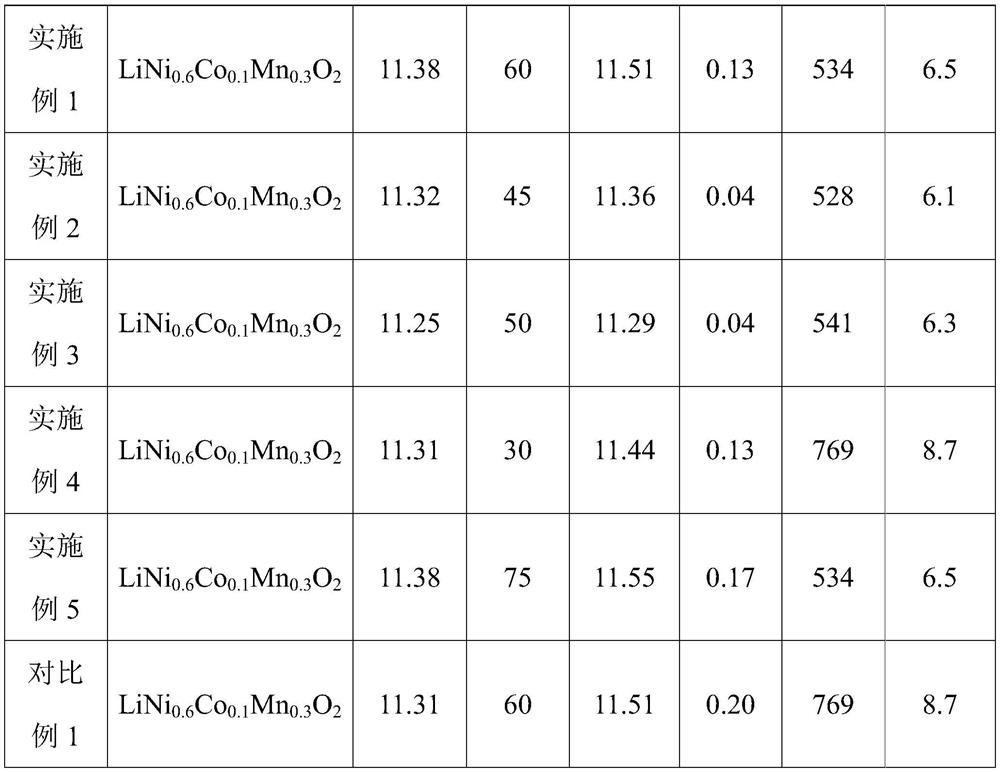

Embodiment 1

[0062] This embodiment provides a positive electrode material (D50 is 2 μm). After the positive electrode material passes through the determination method of the above specific embodiment, the difference between n-m is shown in Table 1, and the chemical formula of the positive electrode material is also shown in Table 1.

[0063] The conditions of ball milling are:

[0064] In this embodiment, the PM100 equipment of Laichi Company is selected, and 9 zirconia grinding beads with a diameter of 10mm and 20g of positive electrode material are added to the material tank, that is, the volume-to-mass ratio of the ball milling beads to the positive electrode material is 235.5mm 3 / g, run at 300rpm for 60min. The diameter of the sun gear of this equipment is 0.141m, and the acceleration g of the ball mill can be calculated to be 69.5m / s 2 .

[0065] The preparation method of the cathode material provided in this embodiment is as follows:

[0066] Choose Ni 0.6 co 0.1 m 0.3 (OH) ...

Embodiment 2

[0068] This example provides a positive electrode material (D50 is 3.2 μm). After the positive electrode material passes through the determination method of the above specific embodiment, the difference between n-m is shown in Table 1, and the chemical formula of the positive electrode material is also shown in Table 1.

[0069] The conditions of ball milling are:

[0070] In this embodiment, the PM100 equipment of Laichi Company is selected, and 10 zirconia grinding beads with a diameter of 10mm and 21g of positive electrode material are added to the material tank, that is, the volume-to-mass ratio of the ball milling beads to the positive electrode material is 250mm 3 / g, run at 350rpm for 45min. The diameter of the sun gear of this equipment is 0.141m, and the acceleration g of the ball mill can be calculated to be 69.5m / s 2 .

[0071] The preparation method of the cathode material provided in this embodiment is as follows:

[0072] Choose Ni 0.6 co 0.1 m 0.3 (OH) 2 ...

Embodiment 3

[0074] This example provides a positive electrode material (D50 is 4 μm). After the positive electrode material passes through the determination method of the above specific embodiment, the difference between n-m is shown in Table 1, and the chemical formula of the positive electrode material is also shown in Table 1.

[0075] The conditions of ball milling are:

[0076] In this embodiment, the PM100 equipment of Laichi Company is selected, and 8 zirconia grinding beads with a diameter of 10mm and 20.5g of positive electrode material are added to the material tank, that is, the volume-to-mass ratio of the ball milling beads to the positive electrode material is 204.3mm 3 / g at a speed of 300rpm for 50min. The diameter of the sun gear of this equipment is 0.141m, and the acceleration g of the ball mill can be calculated to be 69.5m / s 2 .

[0077] The preparation method of the cathode material provided in this embodiment is as follows:

[0078] Choose Ni 0.6 co 0.1 m 0.3 (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com