Electrode plate and lithium ion battery comprising same

A lithium-ion battery and electrode sheet technology, applied in secondary batteries, non-aqueous electrolyte battery electrodes, circuits, etc., can solve problems such as short maintenance cycle, diaphragm folds, and metal burrs left at the cutting position, and achieve a smooth appearance , good elongation, and the effect of avoiding capacity loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

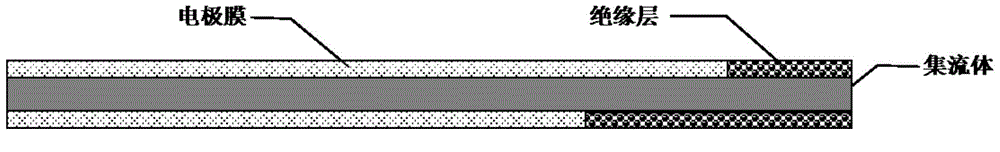

[0042] Example 1 Preparation of electrode sheets

[0043] Preparation of positive electrode active material slurry: the active material lithium iron phosphate, binder PVDF (polyvinylidene fluoride), and conductive carbon black are mixed, and the mixture is uniformly dispersed by high-speed stirring to form a mixture containing the positive electrode active material. In the mixture, the solid component contains 90wt% lithium iron phosphate, 5wt% PVDF and 5wt% conductive carbon black. The mixture uses NMP (N-methylpyrrolidone) as a solvent to prepare positive electrode active material slurry, and the solid content in the slurry is 40 wt%.

[0044]Preparation of negative electrode active material slurry: mix the active material artificial graphite, binder SBR (styrene-butadiene latex), sodium carboxymethyl cellulose and conductive carbon black, and disperse evenly through high-speed stirring to form a mixture containing negative active material . In the mixture, the solid compo...

Embodiment 2

[0052] Example 2 Preparation of lithium ion battery

[0053] The diaphragm of the lithium-ion battery is an 8 μm polypropylene diaphragm, the electrolyte is a lithium hexafluorophosphate electrolyte containing 1M, and the solvent is a mixture of ethylene carbonate / dimethyl carbonate / 1,2 propylene glycol carbonate-1:1:1 (volume ratio) solvent.

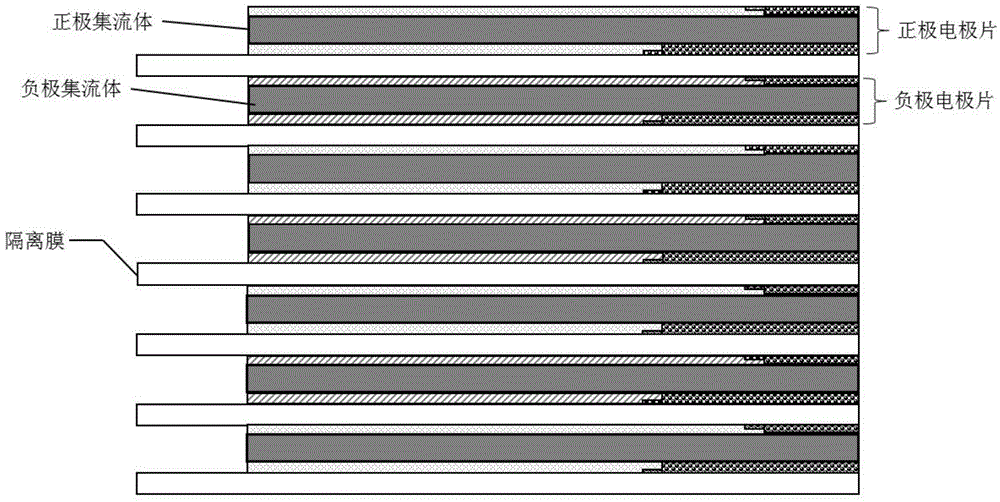

[0054] The positive electrode sheet, separator, and negative electrode sheet prepared in Example 1 are sequentially stacked to form a layered structure to form a bare cell, and after packaging, liquid injection, chemical formation and other processes, a stacked lithium-ion battery or roll Winding lithium-ion battery.

[0055] The relationship between the serial number of the lithium-ion battery and the battery type, the positive pole piece used and the negative pole piece used is shown in Table 2.

[0056] Table 2

[0057] battery number

Embodiment 3

[0058] Embodiment 3 Test of battery capacity

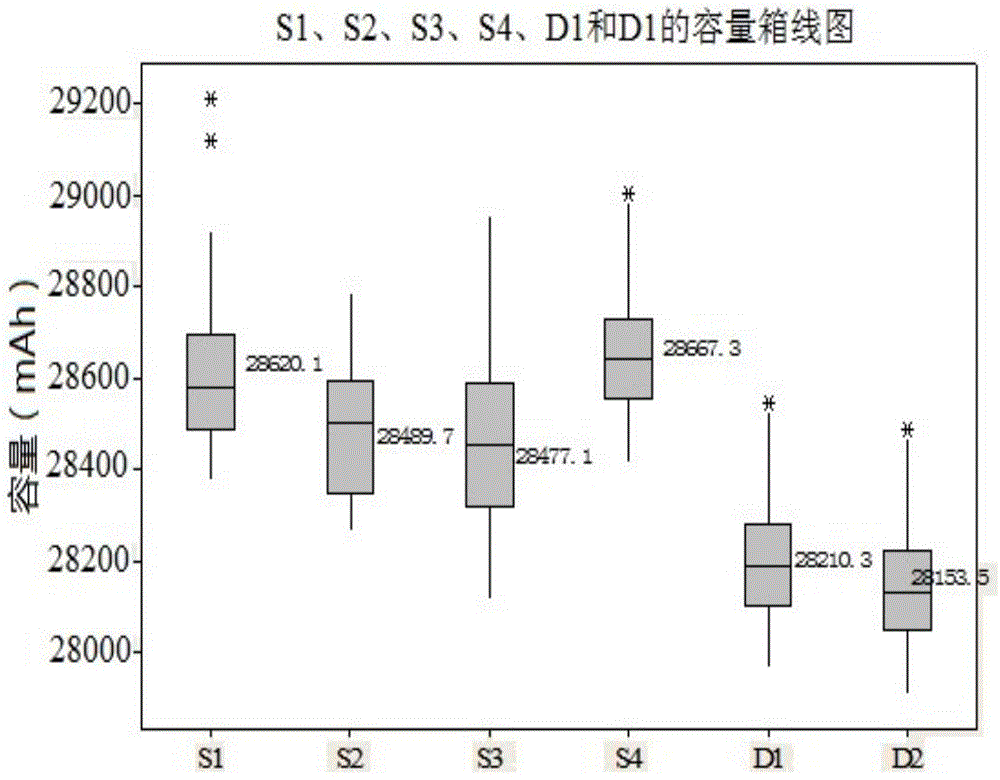

[0059] Take out 20 lithium-ion batteries S1~S4 and D1, D2 obtained in embodiment 2 respectively according to carry out room temperature capacity test, same size battery, the capacity average value of the battery of different groups is as follows image 3 shown.

[0060] Combining Table 1 and image 3 From the data, it can be seen that the battery capacity of the S1-S4 groups adopting the technical solution of the present application is higher than that of the D1 and D2 groups. Since the solid insulating material in the insulating layer of the electrode sheets used in groups D1 and D2 is Al with high hardness 2 o 3 (Mohs hardness level 9), TiO 2 (Mohs hardness 6-7), in the compaction process of lithium-ion batteries, Al 2 o 3 and TiO 2 The prepared insulating layer, because the filled ceramic particles are relatively hard, is not prone to inter-particle slippage and particle breakage, resulting in a relatively small elongati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com