Polishing liquid and polishing method using the same

A technology of polishing liquid and barrier layer, which is applied in the field of polishing liquid and can solve problems such as scratches, erosion, and depressions on polished metal surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0187] A polishing liquid having the following formula (1) was prepared, and a polishing experiment was carried out using it.

[0188] Recipe (1)

[0189] α-alumina (Mohs hardness: 8 to 9, particle size 50nm) (polishing particles): 100g / l

[0190] Citric acid (manufactured by Wako Pure Chemical Industries, ltd.) (organic acid): 15 g / l

[0191] Benzotriazole (BTA) (corrosion inhibitor): 1g / l

[0192] Pure water was added to bring the total volume of the polishing solution to 1000ml.

[0193] As an oxidizing agent, 20 ml of hydrogen peroxide was added per 1 liter of the polishing solution.

[0194] The pH of the resulting polishing solution was adjusted to 5.0 with ammonia water and nitric acid.

[0195] Evaluation method

[0196] MA-300D (trade name, manufactured by Musashino Denshi) was used as a polishing device, and while the slurry was supplied, each wafer film shown below was polished under the following conditions:

[0197] Workbench rotation number: 112rpm

[0198...

Embodiment 2 to 45 and comparative example 1 to 10

[0210] The polishing experiment was carried out under the same conditions as those of Example 1, except that: Polishes prepared by changing the composition (1) of Example 1 to the compositions described in Tables 1 to 6 below were used. liquid. The results obtained are shown in Tables 1 to 6

[0211] The names of compounds abbreviated in Tables 1 to 6 described above are shown below:

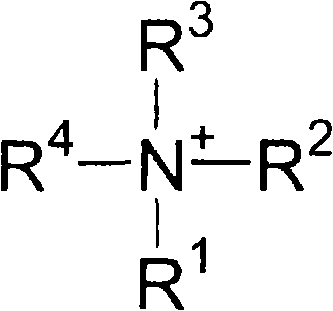

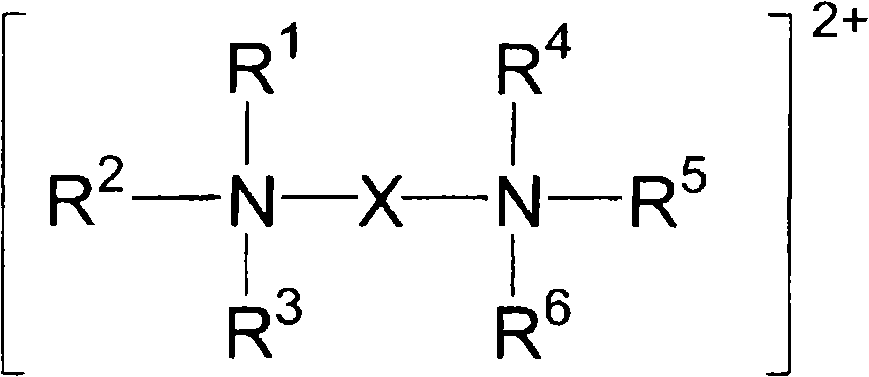

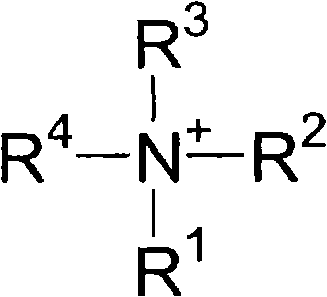

[0212] TBA: tetrabutylammonium nitrate (cationic quaternary ammonium compound);

[0213] TMA: tetramethylammonium nitrate (cationic quaternary ammonium compound);

[0214] HMC: hexanediamine chloride (cationic quaternary ammonium compound);

[0215] BTA: 1,2,3-Benzotriazole (corrosion inhibitor);

[0216] HMBTA: 1-(hydroxymethyl)benzotriazole (corrosion inhibitor);

[0217] DCEBTA: 1-(1,2-dicarboxyethyl)benzotriazole (corrosion inhibitor);

[0218] DBSA: dodecylbenzenesulfonic acid (surfactant); and

[0219] LTM: lauryltrimethylammonium nitrate (surfactant)

[0220]

[0221]

[022...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com