Wool lubricating oil easy to emulsify

A crude oil and emulsifier technology, applied in textiles and papermaking, fiber processing, animal fibers, etc., can solve the problems of wasting time, increasing equipment, harmful to human body, etc., and achieve the effect of good lubricity, stable emulsion and high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

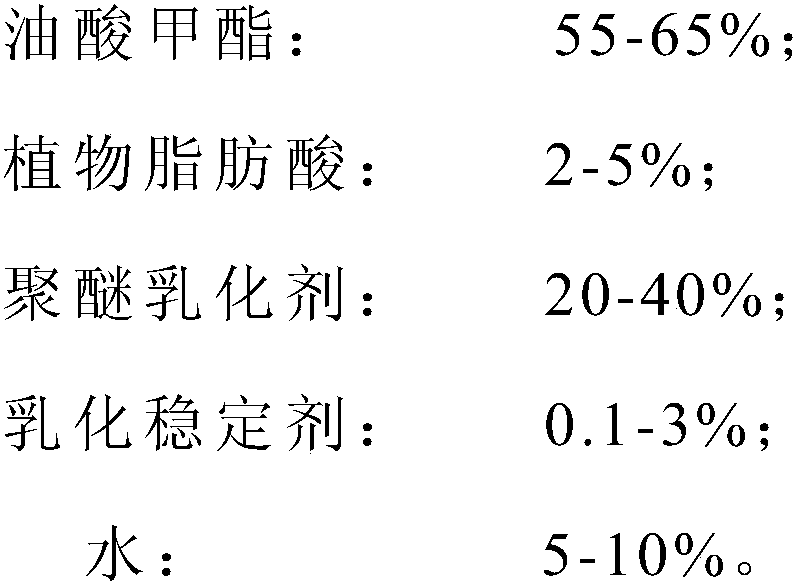

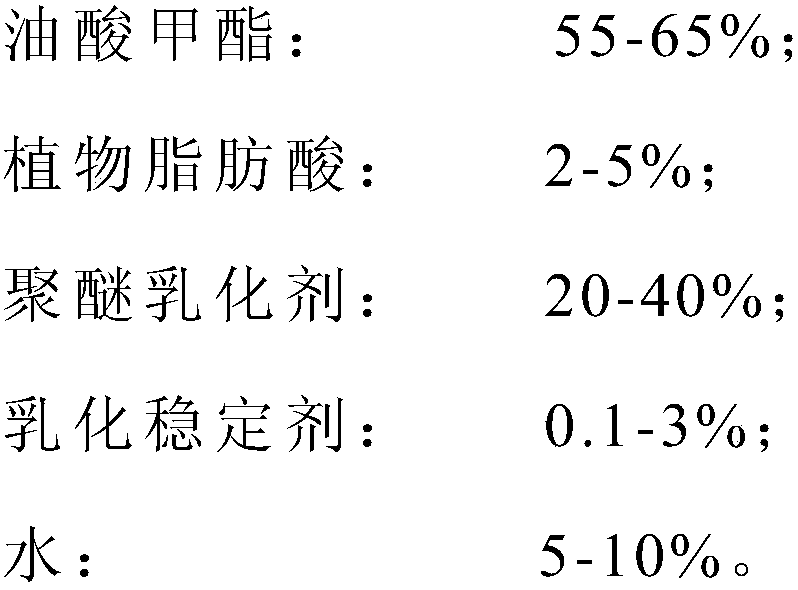

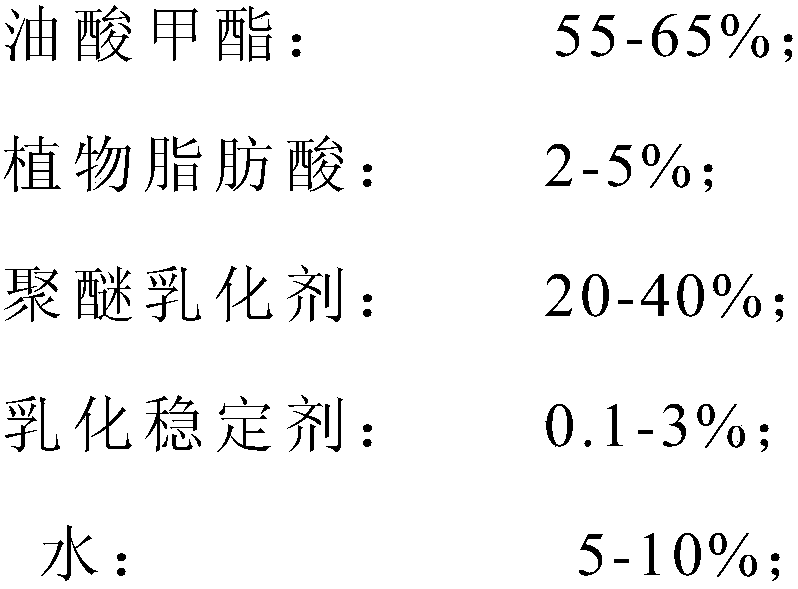

Method used

Image

Examples

Embodiment 1

[0019] An easily emulsified and crude oil, its components and their contents are: methyl oleate: 55%; coconut oleic acid: 4%, linoleic acid: 1%; AEO-3: 3%, 1307: 10% ; 1309: 5%, isooctyl alcohol polyoxyethylene ether (EO=9): 12%; lauryl alcohol 0.1%; water 9.9%. Rapid emulsification at 0°C without stirring, the emulsified emulsion is stable and can be kept without stratification for 48 hours; it has good lubricity, clustering and antistatic properties, and is easy to clean.

Embodiment 2

[0021] An easily emulsified and crude oil, its components and their contents are: methyl oleate: 65%; palm oleic acid: 1%, lauric acid: 1%; 1303: 4%, 1007: 8%; 1312: 5%, isooctanol polyoxyethylene ether (EO=7): 8%; isooctanol 1%, isodecyl alcohol 1%, isotridecyl alcohol 1%; water 5%. Rapid emulsification at 0°C without stirring, the emulsified emulsion is stable and can be kept without stratification for 48 hours; it has good lubricity, clustering and antistatic properties, and is easy to clean.

Embodiment 3

[0023] An easily emulsified and crude oil, its components and their contents are: methyl oleate: 60%; myristic acid: 2%, linoleic acid: 1%; 1003: 2%, 1303: 2%; AEO -7: 10%, 1307: 5%, 1009: 5%, isooctyl alcohol polyoxyethylene ether (EO=9): 5%; octanol 1.5%, lauryl alcohol 0.5%; water 6%. Rapid emulsification at 0°C without stirring, the emulsified emulsion is stable and can be kept without stratification for 48 hours; it has good lubricity, clustering and antistatic properties, and is easy to clean.

[0024] The easy-emulsifying and crude oil of the invention has good application performance and is suitable for wool processing under various conditions. There is no need to stir during the processing, and the crude oil is directly added to the tank, and the water can be emulsified, reducing the time and cost of the process; the emulsification performance is good, stable and not delaminated; the use of polyether emulsifiers is more environmentally friendly; the content of methyl ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com