Multifunctional cleaning agent for aviation aluminum material and preparation method

A multi-functional, cleaning agent technology, applied in the field of aluminum alloys, can solve the problems that cannot meet the cleaning requirements of aviation aluminum materials, accelerate the electrochemistry of metal surfaces, and scrap parts, etc., to achieve easy biodegradation and treatment emissions, flexible and diverse use methods, The effect of good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This example provides a kind of multifunctional cleaning agent that is used for aviation aluminum material, comprises the preparation raw material of following parts by weight:

[0045] Phosphate-free cleaning aids: 0.1 to 5 parts,

[0046] Composite corrosion inhibitor: 1.5 to 15 parts,

[0047] Antirust agent: 0.5 to 10 parts,

[0048] Composite surfactant: 10-40 parts

[0049] Complexing agent: 0.5 to 5 parts,

[0050] Solubilizer: 1 to 15 parts,

[0051] Antifungal agent: 0.1 to 0.5 parts

[0052] Defoamer: 0.1 to 5 parts

[0053] Water: 5-100 parts;

[0054] Composite corrosion inhibitors include aluminum corrosion inhibitors, copper corrosion inhibitors and magnesium corrosion inhibitors;

[0055] Complex surfactants include nonionic surfactants, anionic surfactants and zwitterionic surfactants.

[0056] Wherein, the phosphorus-free cleaning aid is at least one of anhydrous sodium metasilicate, sodium benzoate, sodium citrate, sodium sulfate and sodium bic...

Embodiment 2

[0071] This example provides a multifunctional cleaning agent for aviation aluminum materials. The preparation method is: weigh each component according to the proportion, add water into the container, add a composite corrosion inhibitor to dissolve, and then add non-phosphorus cleaning aids in sequence. Agents, complex surfactants, rust inhibitors, complexing agents, solubilizers, antifungal agents and defoamers.

[0072] It is necessary to ensure that the metal corrosion inhibition system substances are fully dissolved and stirred evenly before adding other components, because there is a sufficient amount of water and the corrosion inhibition system substances can be completely dissolved and uniform in the reactor for 1 hour, and there is no need for a separate heating reaction to produce corrosion inhibitors. corrosion compound.

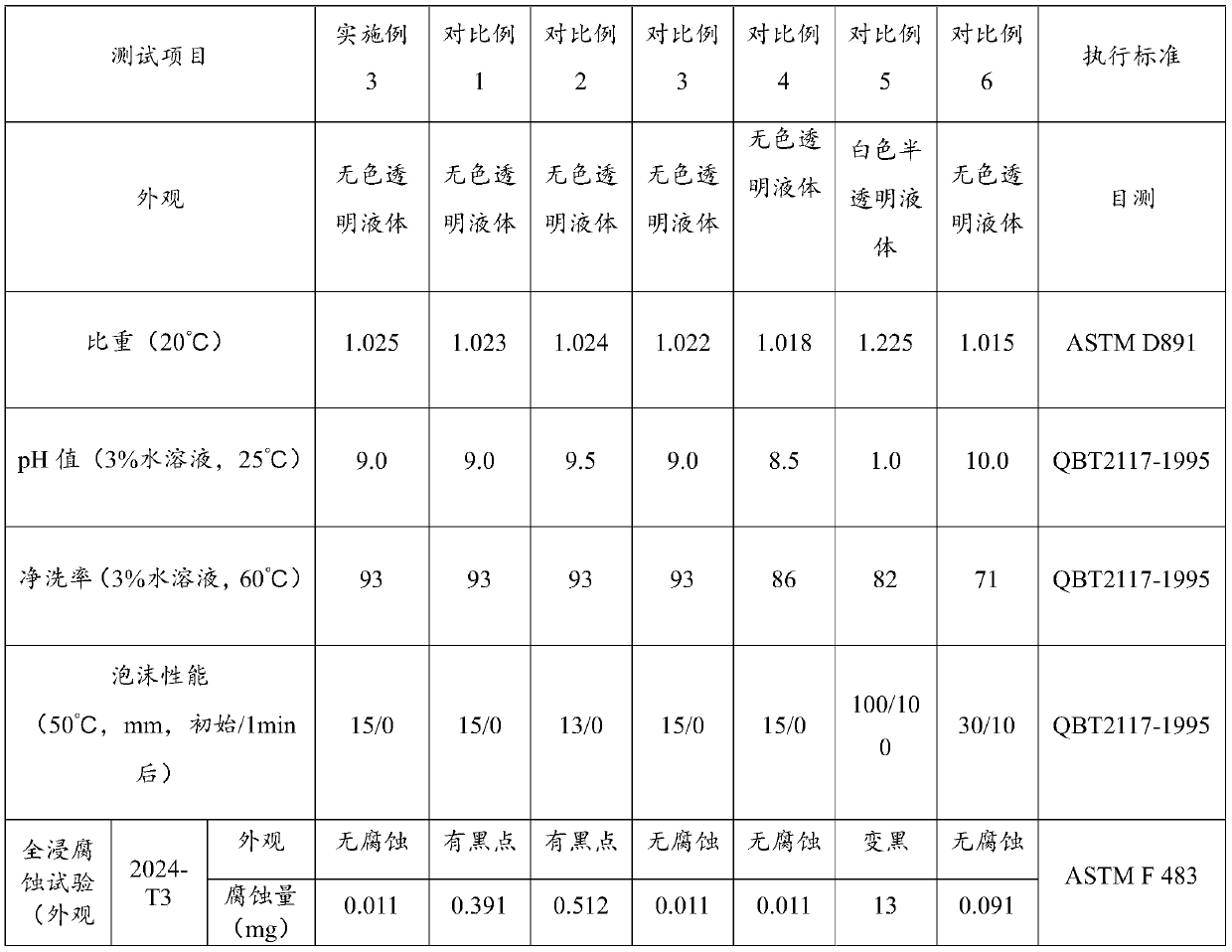

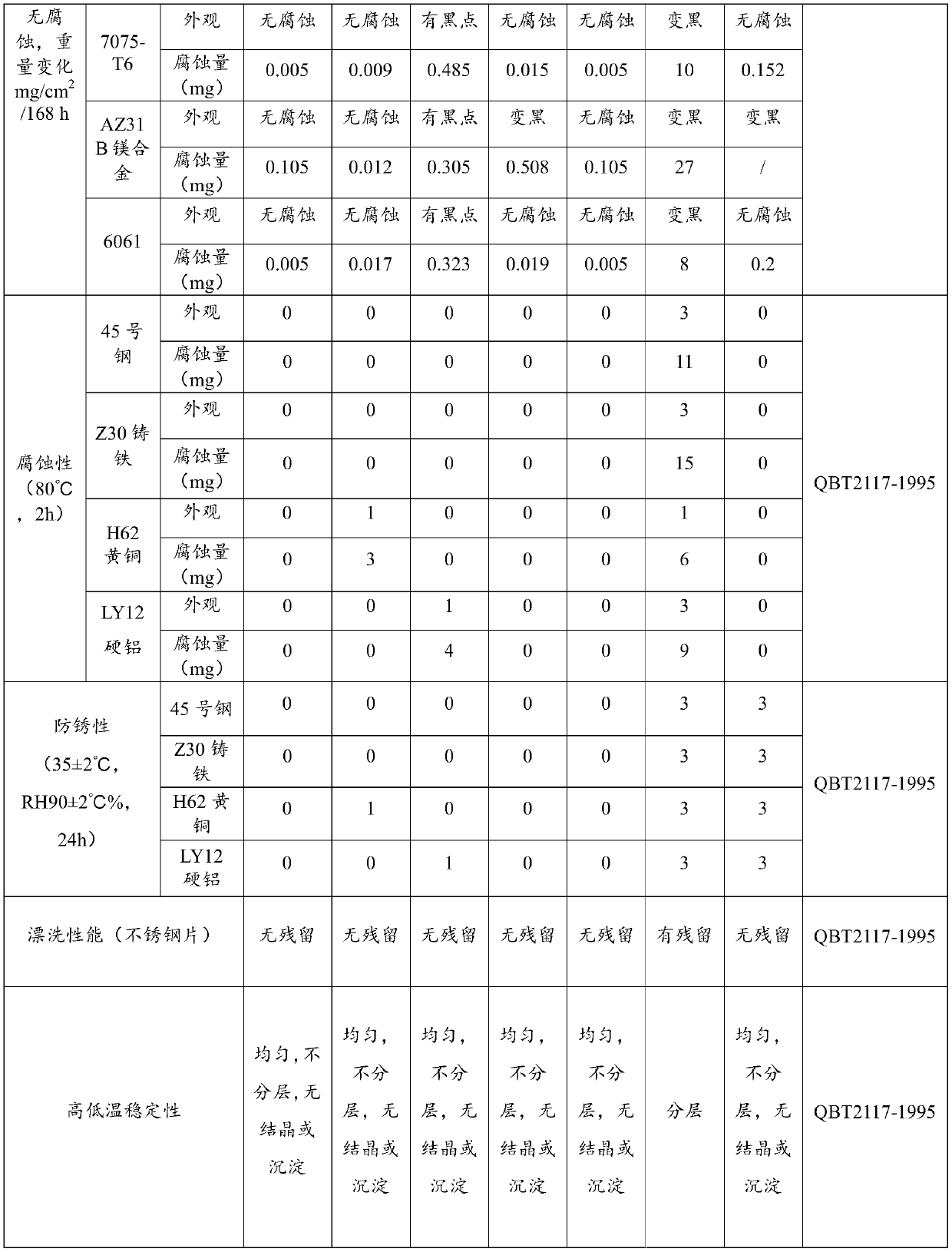

Embodiment 3

[0074] In this example, the preparation method of Example 2 is adopted, and a multifunctional cleaning agent for aviation aluminum materials is prepared according to the formula provided in Example 1. The specific formula is as follows:

[0075] Phosphate-free cleaning aids: 1 part of sodium benzoate, 2 parts of sodium sulfate and 0.3 part of sodium bicarbonate,

[0076] Aluminum corrosion inhibitor ASI-80: 0.5 parts,

[0077] Copper corrosion inhibitor BTA: 0.5 part,

[0078] Magnesium corrosion inhibitor dimethyl imidazoline: 0.5 parts,

[0079] Rust inhibitor dodecyl carbon dibasic organic acid amide: 6 parts,

[0080] Nonionic surfactant LF-221: 10 parts,

[0081] Anionic surfactant AEO-9: 1 part,

[0082] Zwitterionic surfactant lauryl dimethyl betaine: 5 parts,

[0083] Complexing agent NTA: 0.5 parts,

[0084] Solubilizer Triton H66: 5 parts,

[0085] Antifungal agent potassium sorbate: 0.5 parts,

[0086] Antifoaming agent polydimethylsiloxane: 0.1 parts,

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com