Self-emulsification rosinyl surfactant emulsion and preparation method thereof

A surfactant and rosin-based technology, which is applied in the field of self-emulsifying rosin-based surfactant emulsion preparation, can solve the problems of difficult operation, high viscosity of oil-soluble emulsifiers, environmental pollution, etc., and achieve increased added value and low product toxicity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A self-emulsifying rosin-based surfactant emulsion, its general structural formula is as follows:

[0022] R-PEG-R, in the formula, R is rosin or modified rosin, and the modified rosin is disproportionated rosin, hydrogenated rosin or polymerized rosin. PEG is low molecular weight polyethylene glycol with a molecular weight of 200 or 400.

Embodiment 2

[0024] The preparation method of self-emulsifying rosin-based surfactant emulsion, synthesis comprises the following steps:

[0025] Respectively take by weighing rosin and Polyethylene Glycol 400 that the molar ratio is 2: (1-1.1) and pour in the 500ml four-neck flask, then add appropriate amount of zinc oxide (the amount of zinc oxide accounts for about 0.1-0.2% of the rosin quality) ) as a catalyst, heated to 230-280°C to make it fully react, control the reaction process by measuring the acid value of the reactant, when the acid value drops to about 10, the reaction is basically completed, and the material is cooled and discharged.

[0026] Described rosin and polyethylene glycol reaction conditions are:

[0027] The mol ratio of rosin and Polyethylene Glycol is 2: (1-1.1), for example ratio is selected as: 2: 1, 2: 1.05, 2: 1.1, the consumption of zinc oxide can be selected 0.1%, 0.12%, 0.14%, 0.16%, 0.18%, 0.2%. React at 230-280°C for 5-8 hours, the reaction temperature...

Embodiment 3

[0038] Take by weighing respectively disproportionated rosin and Polyethylene Glycol 200 with a molar ratio of 2: 1.1 and pour them into a 500ml four-necked flask, then add an appropriate amount of zinc oxide (the amount of zinc oxide accounts for about 0.15% of the rosin quality) as a catalyst, and heat It is fully reacted at 230°C, and when the acid value drops to about 10, the reaction is basically completed, and the material is cooled and discharged.

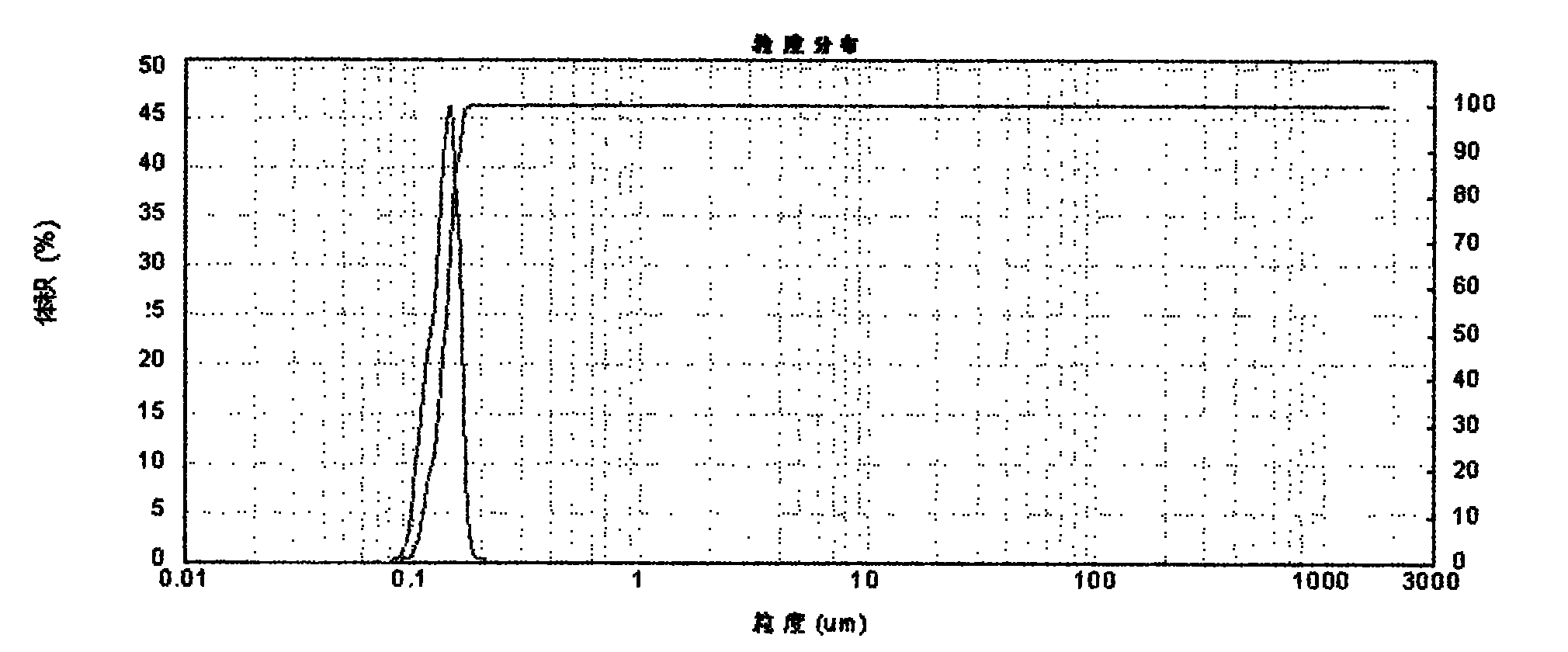

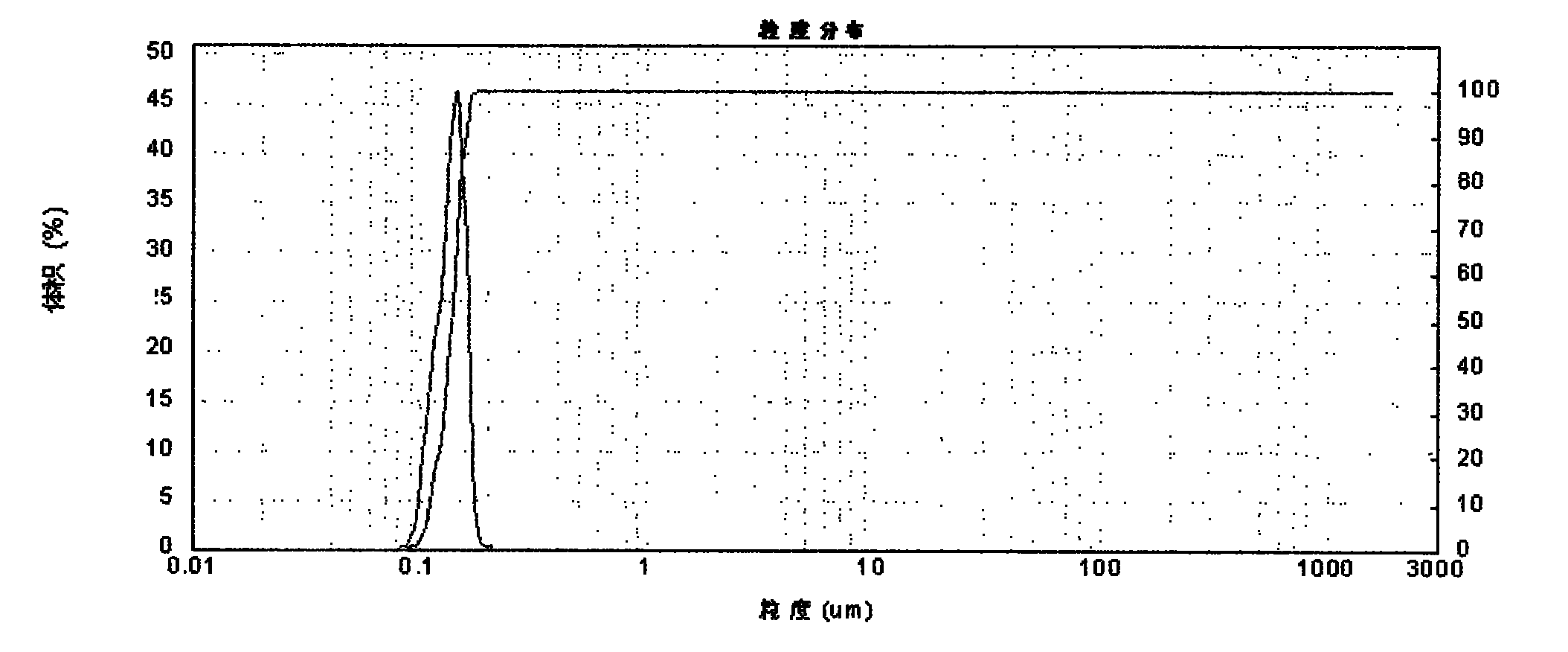

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com