Processing technology capable of improving soup stock dissolving performance

A kind of processing technology, high soup technology, applied in the processing technology field of high soup processing technology and improving the solubility of high soup, it can solve the problems such as difficult to fully dissolve calcium, poor absorption of calcium acetate, etc., to achieve rapid dissolution and beneficial to the human body Effect of absorption and taste improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

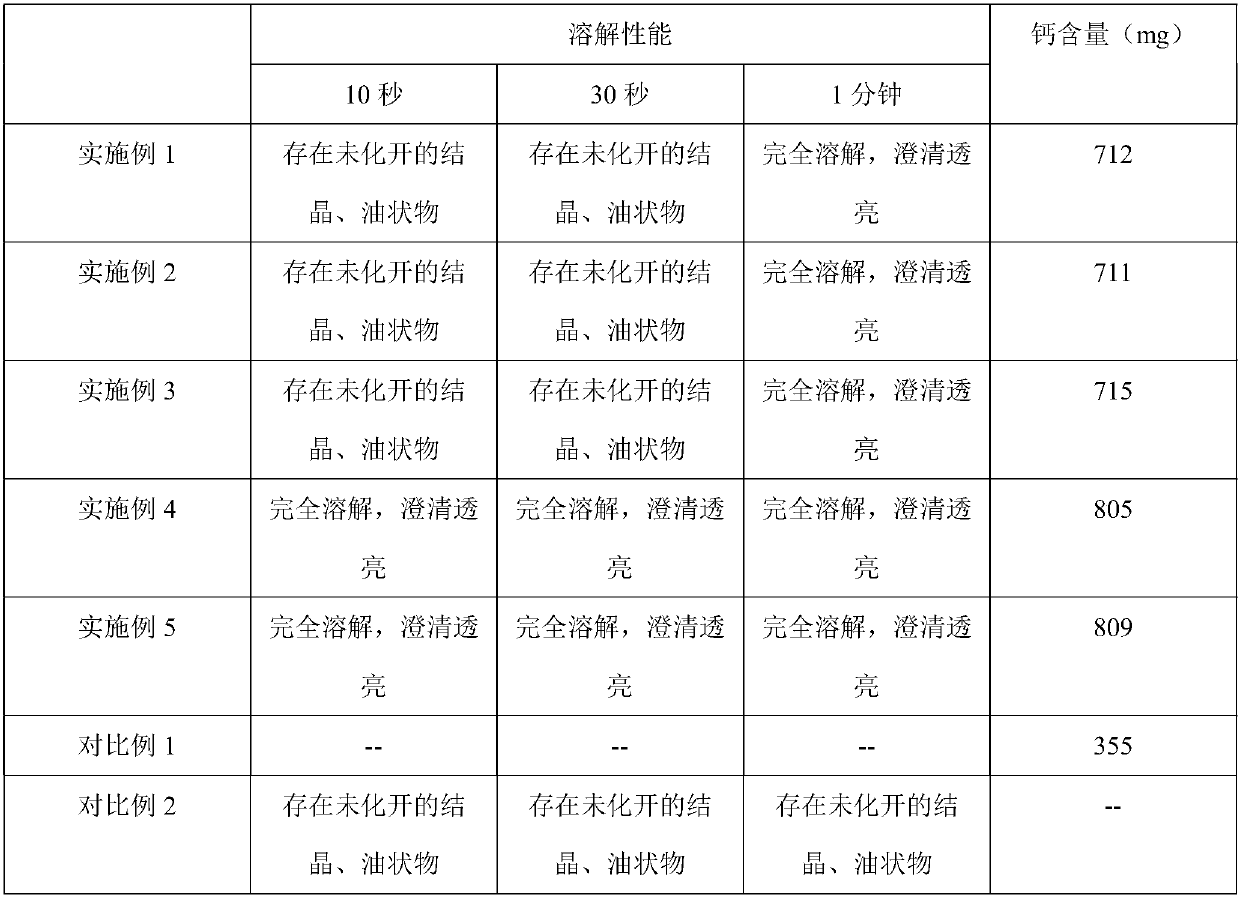

Examples

Embodiment 1

[0053] A processing technology for improving the dissolving performance of broth, the specific steps are as follows:

[0054] (1) Crushing with a powerful bone breaker: crush fresh and clean livestock bones to 3mm through a strong bone breaker to obtain broken bones;

[0055] (2) High-temperature and high-pressure cooking: put broken bones and water into a cooking tank at a mass ratio of 1:3 for high-temperature and high-pressure cooking. The process conditions for high-temperature and high-pressure cooking are: cooking at 135° C. and 0.4 MPa for 3 hours;

[0056] (3) Vacuum concentration: control the parameters of each effect body by adjusting the feed amount and steam pressure. blending tank;

[0057] (4) Deployment;

[0058] (5) Homogenization: Turn on the homogenizer, homogenization pressure: 20MPa, homogenize once;

[0059] (6) Sterilization: heat up to 78°C and keep warm for 35 minutes;

[0060] (7) emulsification: grind once through colloid mill;

[0061] (8) Packa...

Embodiment 2

[0070] A processing technology for improving the dissolving performance of broth, the specific steps are as follows:

[0071] (1) Crushing with a powerful bone breaker: crush fresh and clean livestock bones to 5mm through a strong bone breaker to obtain broken bones;

[0072] (2) High-temperature and high-pressure cooking: put broken bones and water into a cooking tank at a mass ratio of 1:1 for high-temperature and high-pressure cooking. The process conditions for high-temperature and high-pressure cooking are: cooking at 140° C. and 0.35 MPa for 5 hours;

[0073] (3) Vacuum concentration: Control the parameters of each effect by adjusting the feed amount and steam pressure. blending tank;

[0074] (4) Deployment;

[0075] (5) Homogenization: Turn on the homogenizer, homogenization pressure: 15MPa, homogenize once;

[0076] (6) Sterilization: heat up to 82°C and keep warm for 30 minutes;

[0077] (7) emulsification: grind once through colloid mill;

[0078] (8) Packaging...

Embodiment 3

[0087] A processing technology for improving the dissolving performance of broth, the specific steps are as follows:

[0088] (1) Crushing with a powerful bone breaker: crush fresh and clean livestock bones to 4mm through a strong bone breaker to obtain broken bones;

[0089] (2) High-temperature and high-pressure cooking: put broken bones and water into a cooking tank at a mass ratio of 1:2 for high-temperature and high-pressure cooking. The process conditions for high-temperature and high-pressure cooking are: cooking at 137°C and 0.38MPa for 4 hours;

[0090] (3) Vacuum concentration: Control the parameters of each effect by adjusting the feed amount and steam pressure. blending tank;

[0091] (4) Deployment;

[0092] (5) Homogenization: Turn on the homogenizer, homogenization pressure: 18MPa, homogenize once;

[0093] (6) Sterilization: heat up to 80°C and keep warm for 32 minutes;

[0094] (7) emulsification: grind once through colloid mill;

[0095] (8) Packaging: P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com