Amino silicone oil emulsion and preparation method thereof

A technology of amino silicone oil and emulsion, which is applied in the field of silicone oil emulsion, can solve the problems of long preparation and stirring process, poor dispersion of emulsion particle size, difficulty in emulsification of amino silicone oil, etc., and achieve uniform particle size, good stability, and shorten the production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

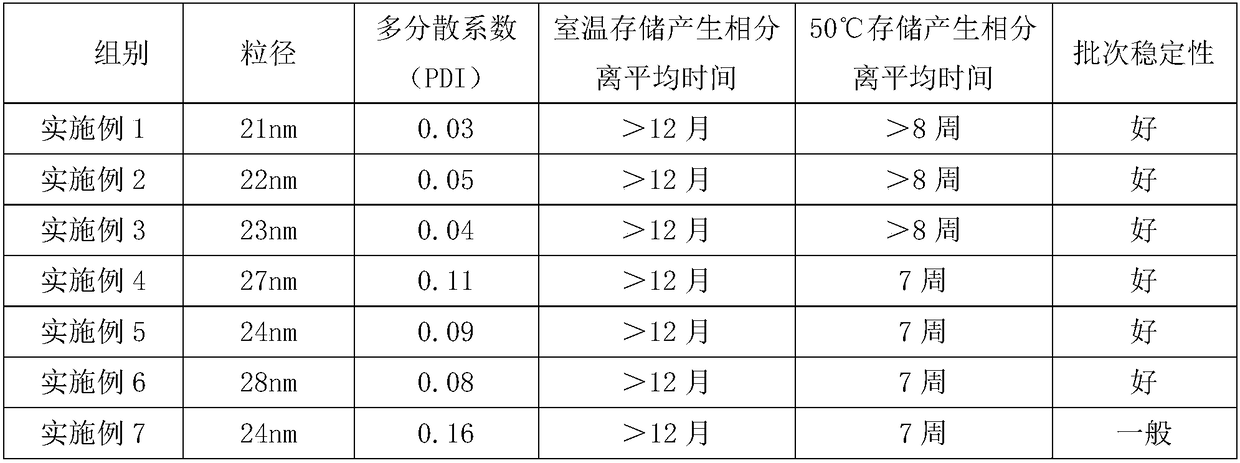

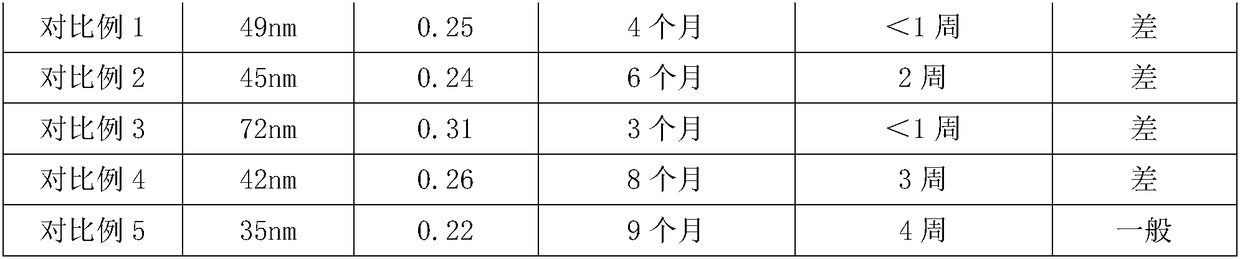

Examples

Embodiment 1

[0025] A kind of amino silicone oil emulsion of the present embodiment is made up of the raw material of following mass percentage: Amino silicone oil 50g, deionized water 39g, surfactant 8g, distearoylphosphatidylglycerol 0.7g, pH adjusting agent 2.3g; Active agent is made up of 1.6g macrogol 4000 monooleate, 4.0g polyoxyethylene sorbitan monolaurate and 2.4g cocamidopropyl betaine; Described amino silicone oil is made of 60% viscosity 3500mPa.s amino silicone oil with an ammonia value of 0.4 and 40% amino silicone oil with a viscosity of 15000mPa.s and an ammonia value of 0.6 are mixed; the pH regulator is an aqueous solution of acetic acid and sodium hydrogen phosphate, and the amino silicone oil emulsion The pH value is 6.7.

[0026] The amino silicone oil emulsion preparation method of the present embodiment is as follows:

[0027] S1. Weigh all the amino silicone oil, surfactant, distearoylphosphatidylglycerol and 26% deionized water according to the mass ratio and add ...

Embodiment 2

[0034] A kind of amino silicone oil emulsion of the present embodiment is made up of the raw material of following mass percent: Amino silicone oil 42g, deionized water 47g, surfactant 6g, distearoylphosphatidylglycerol 1.1g, pH regulator 3.9g; Active agent is made up of 1.2g macrogol 4000 monooleate, 3.0g polyoxyethylene sorbitan monolaurate and 1.8g cocamidopropyl betaine; Described amino silicone oil is made up of the viscosity of 60%. 3500mPa.s amino silicone oil with an ammonia value of 0.4 and 40% amino silicone oil with a viscosity of 15000mPa.s and an ammonia value of 0.6 are mixed; the pH regulator is an aqueous solution of acetic acid and sodium hydrogen phosphate, and the amino silicone oil emulsion The pH value is 6.5. Its preparation method is with embodiment 1.

Embodiment 3

[0036]A kind of amino silicone oil emulsion of the present embodiment is made up of the raw material of following mass percent: Amino silicone oil 58g, deionized water 31g, surfactant 10g, distearoylphosphatidylglycerol 0.3g, pH adjusting agent 0.7g; Active agent is made up of 2.0g macrogol 4000 monooleate, 5.0g polyoxyethylene sorbitan monolaurate and 3.0g cocamidopropyl betaine; Described amino silicone oil is made of 60% viscosity 3500mPa.s amino silicone oil with an ammonia value of 0.4 and 40% amino silicone oil with a viscosity of 15000mPa.s and an ammonia value of 0.6 are mixed; the pH regulator is an aqueous solution of acetic acid and sodium hydrogen phosphate, the pH of the amino silicone oil emulsion The value is 7.0. Its preparation method is with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com