Dimethyl-monoperfluorodecyl silicon-polyethoxyl-oleate poly-compound, preparation method and application thereof

A technology of perfluorodecyl and polyethoxy is applied in the field of foam oil displacement agents, which can solve the problems of chromatographic separation, weakening and loss of synergistic effect of components, etc., and achieves simple preparation method, promotion of foaming effect, and foam stabilization effect. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The dimethyl-monoperfluorodecyl silicon-polyethoxy-oleate multi-component compound of the present invention has a structural formula of:

[0026]

[0027] Among them, n=10-18.

[0028] The preparation method includes the following steps: first, 50 g of perfluorodecane and 12 g of dimethylfluorosilane are placed in a reactor, protected by nitrogen gas, and stirred and reacted at 60° C. for 1.5 h; secondly, concentrated sulfuric acid is added to the system, and the temperature is raised to to 150°C, slowly add 60g of ethylene oxide, and continue to react for 1.5h; again, cool down to about 100°C, add 28g of oleic acid to react for 1.5h; finally, add sodium hydroxide to adjust the pH value to 9, and the product Invented multi-component compound.

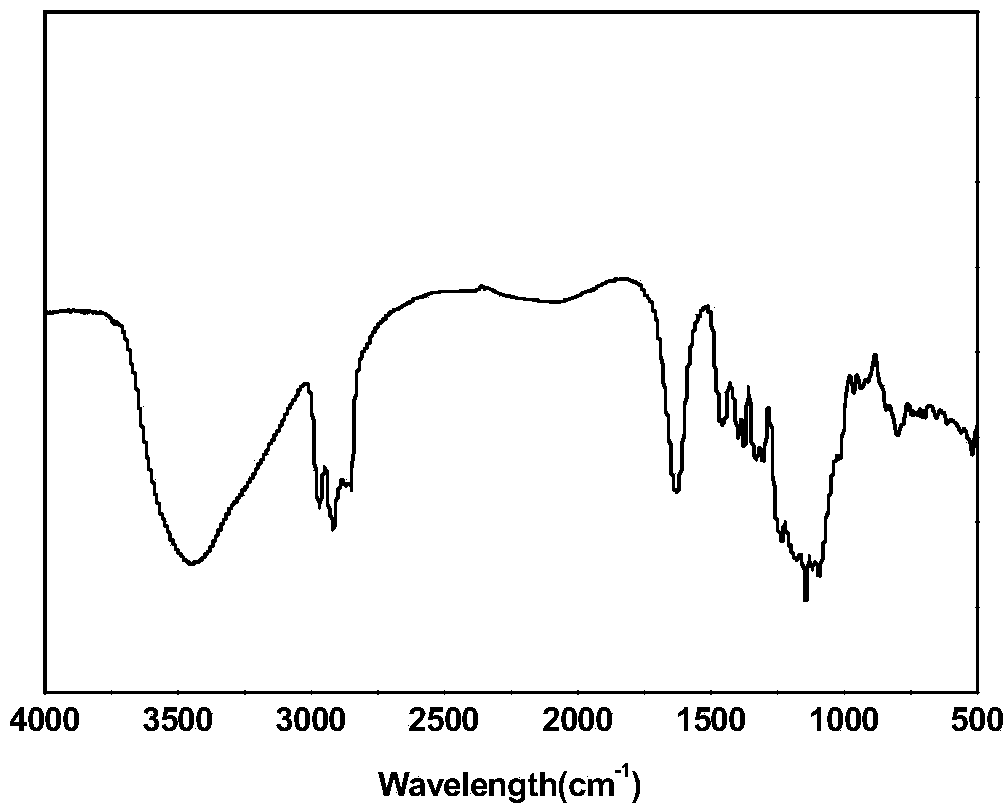

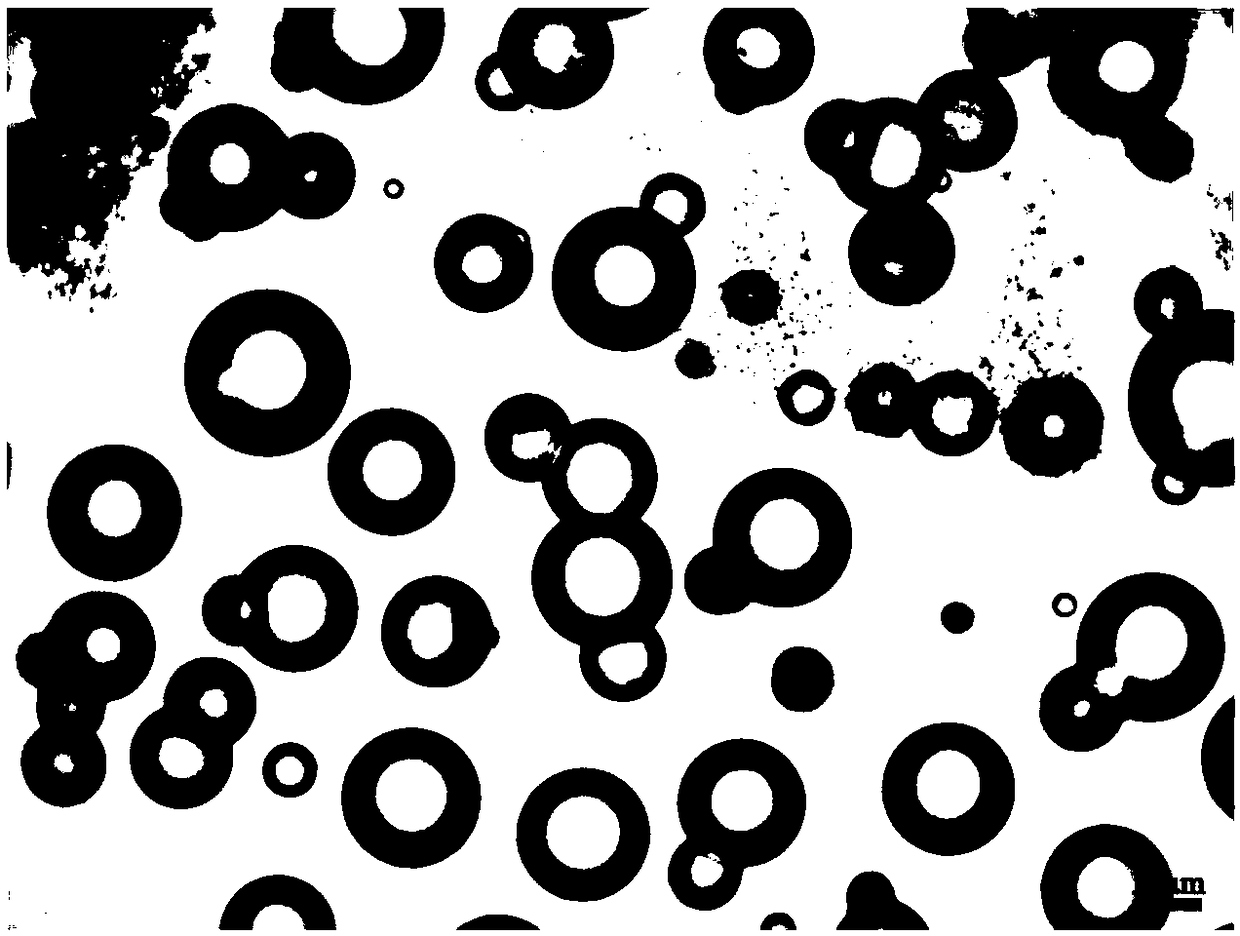

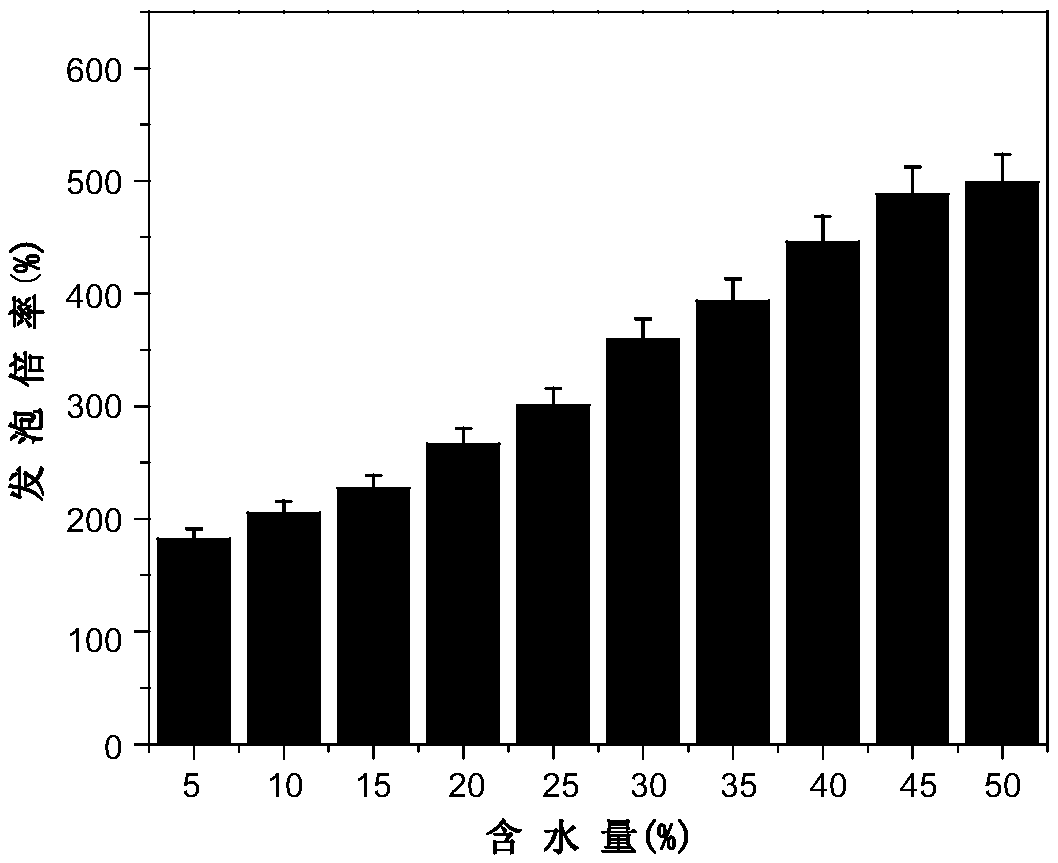

[0029] When the multi-component compound prepared in this example is applied to oil displacement, the surface observation, foaming and foam stabilizing properties of its oil-based foam are characterized, and the obtained resu...

Embodiment 2

[0032] The dimethyl-monoperfluorodecyl silicon-polyethoxy-oleate multi-component compound of the present invention has a structural formula of:

[0033]

[0034] Among them, n=6-14.

[0035]The preparation method includes the following steps: first, 50 g of perfluorodecane and 9.4 g of dimethylfluorosilane are placed in a reactor, protected by nitrogen gas, and stirred at 60° C. for 1.5 h; secondly, concentrated sulfuric acid is added to the system, Raise the temperature to 150°C, slowly add 40g of ethylene oxide, and continue the reaction for 1.5h; again, cool down to about 100°C, add 25g of oleic acid to react for 1.5h; finally, add sodium hydroxide to adjust the pH value to 8.5 to obtain Multi-component compounds of the present invention.

Embodiment 3

[0037] The dimethyl-monoperfluorodecyl silicon-polyethoxy-oleate multi-component compound of the present invention has a structural formula of:

[0038]

[0039] Among them, n=12-16.

[0040] The preparation method includes the following steps: first, 50 g of perfluorodecane and 9.4 g of dimethylfluorosilane are placed in a reactor, protected by nitrogen gas, and stirred at 60° C. for 1.5 h; secondly, concentrated sulfuric acid is added to the system, Raise the temperature to 150°C, slowly add 55g of ethylene oxide, and continue the reaction for 1.5h; again, cool down to about 100°C, and add 26g of oleic acid to react for 1.5h; finally, add sodium hydroxide to adjust the pH value to 8 to obtain Multi-component compounds of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com