Oil-in-water type emulsion based on esterified soybean polysaccharide and preparation method of emulsion

A technology of oil-in-water emulsion and soybean polysaccharide, which is applied in the field of emulsion preparation, can solve the problems of low protein content and low emulsification stability, achieve the effect of improving emulsification performance and broadening the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

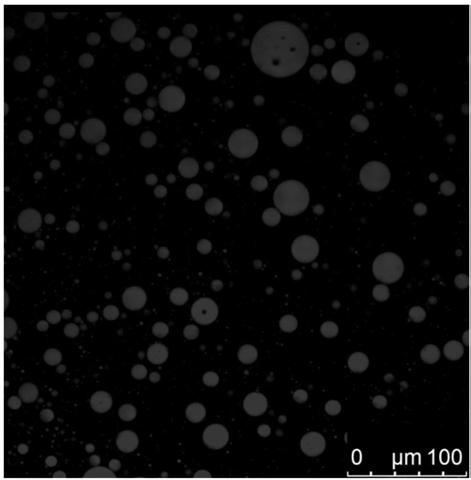

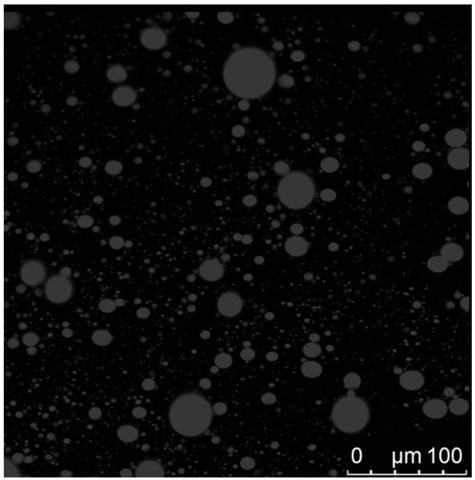

Image

Examples

Embodiment 1

[0028] (1) Prepare the soybean polysaccharide solution, put the solution into an ultrasonic cleaner, control the ultrasonic frequency to 30kHz and conduct a 30°C circulating water bath for 10min, add OSA to the SSPS solution, and perform esterification with OSA:SSPS at a mass ratio of 1:7 reaction, the reaction pH was 8.0, the reaction time was 30 min, and freeze-dried to obtain esterified soybean polysaccharide.

[0029] (2) Add the esterified soybean polysaccharide into deionized water, heat it in a water bath at 40°C for 2 hours until it is completely dissolved, and obtain 40 ml of an esterified soybean polysaccharide solution with a mass fraction of 2%; Soybean oil is added to obtain a mixed solution in which the final mass concentration of soybean oil is 20%.

[0030] (3) The mixed solution was sheared at a speed of 10,000 rpm for 5 minutes under a high-speed shearing machine to obtain an oil-in-water emulsion based on esterified soybean polysaccharide.

Embodiment 2

[0032] (1) Prepare a soybean polysaccharide solution, put the solution into an ultrasonic cleaner, control the ultrasonic frequency to 40kHz and conduct a 35°C circulating water bath for 20min, add OSA to the SSPS solution, and perform esterification with OSA:SSPS at a mass ratio of 1:7.5 reaction, the reaction pH was 8.5, the reaction time was 35 minutes, and freeze-dried to obtain esterified soybean polysaccharide.

[0033] (2) Add the esterified soybean polysaccharide into deionized water, heat it for 1.5 hours in a water bath at 45°C until it is completely dissolved, and obtain 40ml of an esterified soybean polysaccharide solution with a mass fraction of 3%; Soybean oil is added to the mixture to obtain a mixed liquor whose final mass concentration of soybean oil is 25%.

[0034] (3) The mixed solution was sheared at a speed of 13000 rpm for 4 minutes under a high-speed shearing machine to obtain an oil-in-water emulsion based on esterified soybean polysaccharide.

Embodiment 3

[0036] (1) Prepare the soybean polysaccharide solution, put the solution into an ultrasonic cleaner, control the ultrasonic frequency to 40kHz and carry out a 40°C circulating water bath for 30min, add OSA to the SSPS solution, and perform esterification with OSA:SSPS as a mass ratio of 1:8 reaction, the reaction pH was 9.0, the reaction time was 40 min, and the esterified soybean polysaccharide was obtained by freeze-drying.

[0037] (2) Add the esterified soybean polysaccharide into deionized water, heat it for 1 hour in a water bath at 40°C until it is completely dissolved, and obtain 40 ml of an esterified soybean polysaccharide solution with a mass fraction of 4%; Soybean oil is added to obtain a mixed liquor whose final mass concentration of soybean oil is 25%.

[0038] (3) The mixed solution was sheared for 2 minutes at a speed of 15000 rpm under a high-speed shearing machine to obtain an oil-in-water emulsion based on esterified soybean polysaccharide.

[0039] The mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com