Ceramide nano-emulsion and preparation method thereof

A technology of ceramide and nanoemulsion, which is applied in the direction of pharmaceutical formulations, cosmetic preparations, dressing preparations, etc. It can solve the problems of poor stability, poor biocompatibility, and difficulty in achieving efficacy, so as to increase content and reduce usage , good water dispersibility and biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

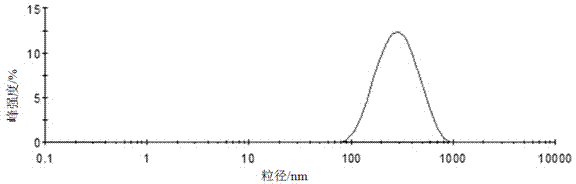

Image

Examples

Embodiment 1

[0034] A ceramide nanoemulsion, calculated by weight percentage, its raw material composition and content are as follows:

[0035] Grease 14 %

[0036] Emulsifier 1 %

[0037] Ceramide 3 %

[0038] Polyol 8 %

[0039] Inorganic salt 0.1 %

[0040] 73.9% of the balance is deionized water;

[0041] The oil is a synthetic oil, and the synthetic oil is caprylic capric triglyceride, a cosmetic grade product provided by Lubrizol (U.S.);

[0042] The emulsifier is a Gemini surfactant, and the Gemini surfactant is bis(lauroylamide glutamine) sodium lysine, a cosmetic grade product produced by Asahi Kasei Co., Ltd. (Japan);

[0043] The ceramide is ceramide 2, a cosmetic grade product provided by Takasago (Japan);

[0044] Described polyhydric alcohol is glycerol, the industrial grade product that Sinopharm Group Chemical Reagent Co., Ltd. provides;

[0045] The inorganic salt is sodium chloride, an industrial-grade product provided by Sinopharm Chemical Reagent Co., Ltd.

[00...

Embodiment 2

[0053] A ceramide nanoemulsion, calculated by weight percentage, its raw material composition and content are as follows:

[0054] Grease 15 %

[0055] Emulsifier 2 %

[0056] Ceramide 1 %

[0057] Polyol 10 %

[0058] Inorganic salt 0.1 %

[0059] 71.9% of the balance is deionized water;

[0060] The oil is vegetable oil, and the vegetable oil is olive oil, an industrial-grade product provided by Dike Fine Chemicals;

[0061] The emulsifier is a Gemini surfactant, and the Gemini surfactant is 1,2-bis[N-methyl-N-dodecyl-N-sulfopropyl]ethylenediamine betaine (GBS12) , industrial-grade products provided by Shanghai Yantuo Biotechnology Co., Ltd.;

[0062] The ceramide is ceramide 2, a cosmetic grade product provided by Takasago (Japan);

[0063] The polyol is 1,3-butanediol, an industrial-grade product provided by Sinopharm Chemical Reagent Co., Ltd.;

[0064] The inorganic salt is potassium chloride, an industrial-grade product provided by Sinopharm Chemical Reagent Co....

Embodiment 3

[0072] A ceramide nanoemulsion, calculated by weight percentage, its raw material composition and content are as follows:

[0073] Grease 12 %

[0074] Emulsifier 0.2 %

[0075] Ceramide 0.8 %

[0076] Polyol 10 %

[0077] Inorganic salt 0.1 %

[0078] 76.9% of the balance is deionized water;

[0079] The oil is vegetable oil, and the vegetable oil is wheat germ oil, an industrial-grade product provided by Dike Fine Chemicals;

[0080] The emulsifier is a Gemini surfactant, and the Gemini surfactant is bis(lauramide glutamine) sodium lysine, a cosmetic grade product produced by Asahi Kasei Co., Ltd. (Japan);

[0081] The ceramide is ceramide 2, a cosmetic grade product provided by Takasago (Japan);

[0082] Described polyhydric alcohol is propylene glycol, the industrial grade product that Sinopharm Chemical Reagent Co., Ltd. provides;

[0083] The inorganic salt is sodium chloride, an industrial-grade product provided by Sinopharm Chemical Reagent Co., Ltd.

[0084] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com