Method for extracting krill oil rich in phospholipids and neutral lipid without using solvent

A technology of krill oil and krill, applied in the direction of fat oil/fat production, medical preparations containing active ingredients, diseases, etc., can solve problems such as unsuccessful results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

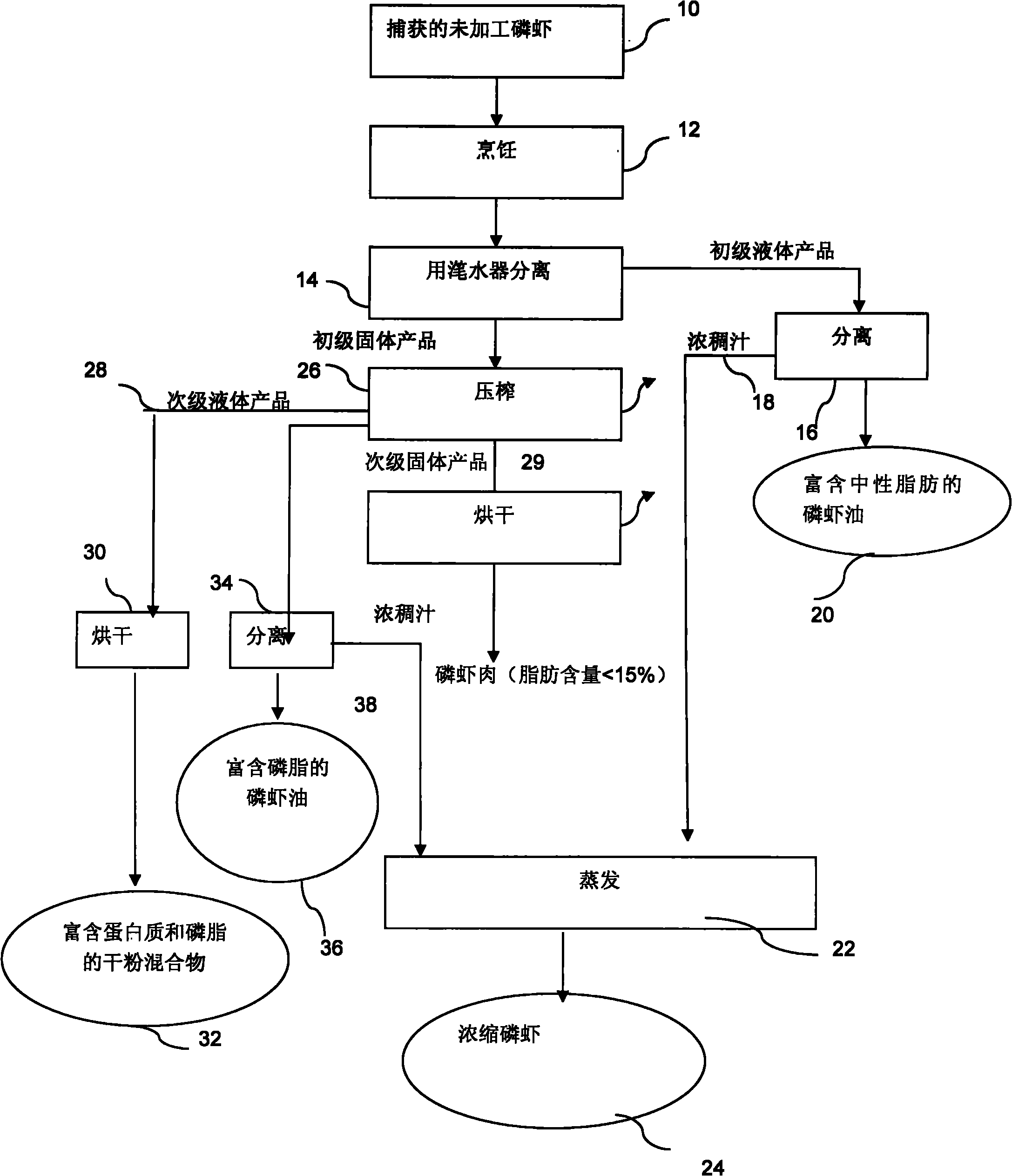

[0234] The technique of obtaining krill oil and low-fat krill among the present invention

[0235] An embodiment of the relevant process method in the present invention is described below. figure 2 It is a flow chart of the process. This process apparently does not involve the use of organic solvents and / or supercritical liquid carbon dioxide.

[0236] Antarctic krill is caught from March to May, preferably in May, when the krill meat is plump. In the fishing grounds of the Orkney Islands, using a pumping system, the krill is captured when it is caught in the container of the factory ship. was alive and was dealt with immediately. Table 5 shows the composition of fresh and natural whole krill.

[0237] table 5

[0238]

[0239]

[0240] All krill are aggregated into bunkers to drain the seawater and transported on conveyor belts to tanks where they are transported to steamer processing by a Stord Disc Cooker RPH-60 Model Progressive Cavity Pump.

[0241] The conve...

Embodiment 2

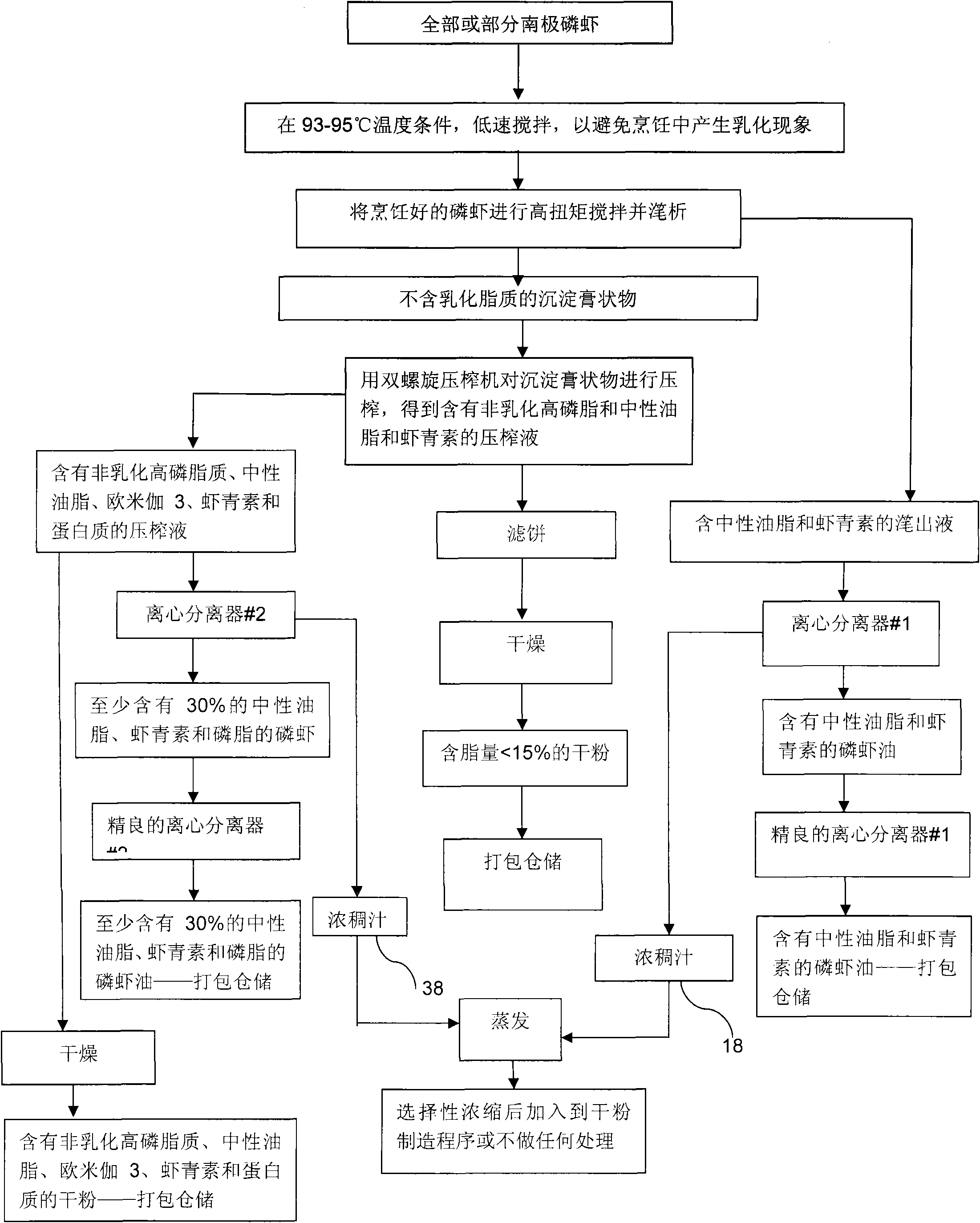

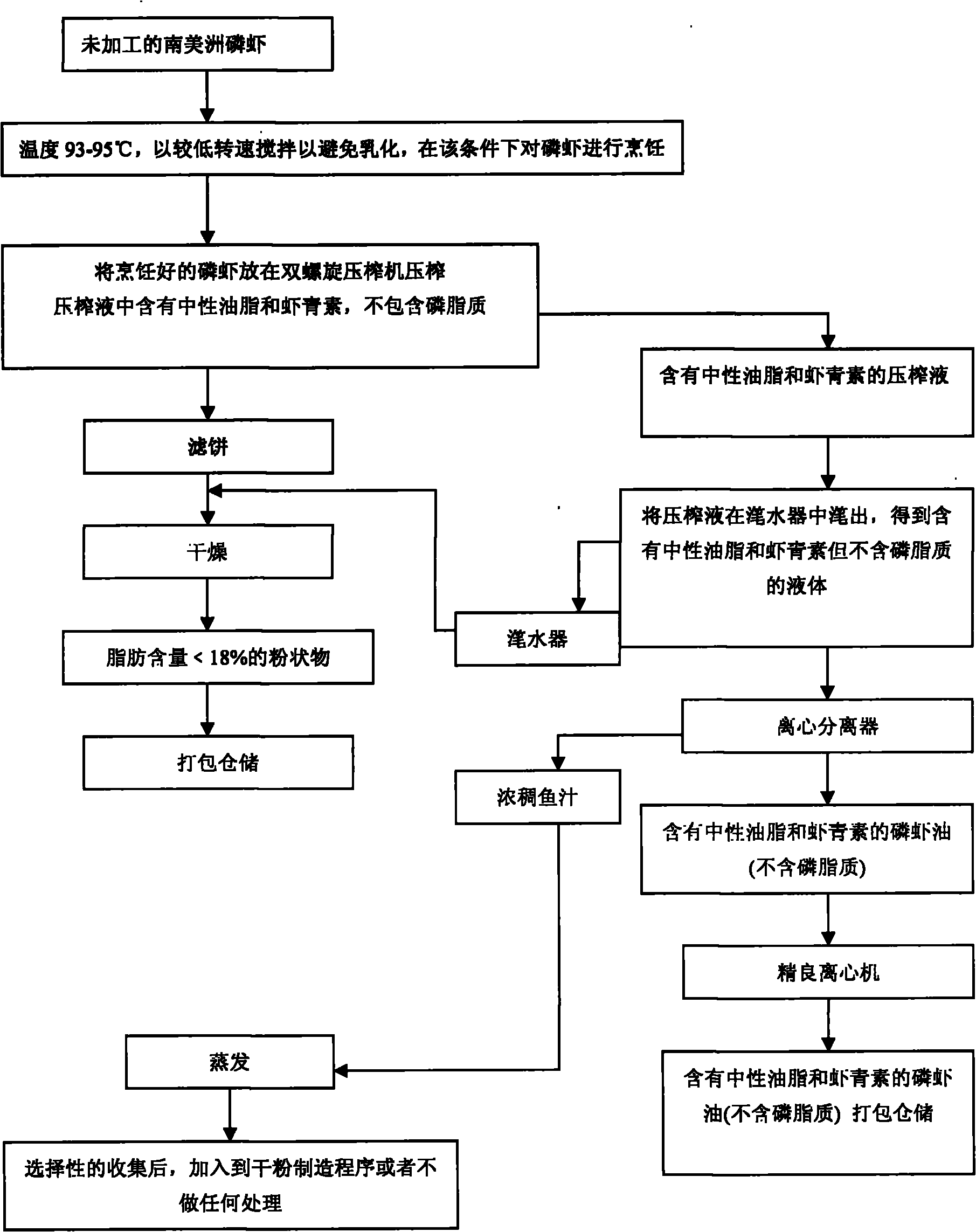

[0252] Flowchart and Quantitative Analysis Comparison of Obtaining Krill Oil and Low-fat Krill Meal Technology in the present invention

[0253] Although the highest fat content of krill must be native Antarctic krill in the absence of water attachment or recovery, this example shows that during periods when native krill is high in fat (estimated at 5%), the present The conclusion of the evaluation of the series production comparison of the inventive product line.

[0254] The following tables are the conclusions of the evaluation of the present invention regarding batch comparisons of production processes using native krill with a high fat content (approximately 5% w / w) in the absence of attached moisture.

[0255] Table 7

[0256]

[0257] Table 8

[0258]

[0259] Table 9

[0260]

[0261]

[0262] Table 10

[0263]

[0264] Table 11

[0265]

[0266] Table 12

[0267]

[0268] Table 13

[0269]

[0270] Table 14

[0271]

[0272]

[02...

example 3

[0339] Krill oil neutral lipid component of the present invention

[0340] Table 43

[0341] Neutral fat %w / w Triglycerides 84.6 Glycerin 4.9 Free fatty acids ND Monoglyceride ND Total: 89.5 Phospholipids ND Alpha-tocopherol 0.7 Fatty Acid Analysis FAME (Fatty Acid Methyl Esters) %w / w Total sample 8:0 0.0 9:0 0.0 10:0 0.0 11:0 0.0 12:0 0.3 13:0 0.0 14:0 16.3 15.6 0.5 16:0 18.2 17:0 0.3 18:0 1.5 19:0 1.0 20:0 0.0 22:0 0.1 23:0 0.0 24:0 0.0 Saturation Total 38.3 11:1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com