Cheese ice cream and preparation method thereof

A technology of ice cream and cheese, which is applied in the field of cheese ice cream and its preparation, can solve the problems of cheese protein defects, etc., and achieve the effect of uniform tissue state, fine texture and perfect combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

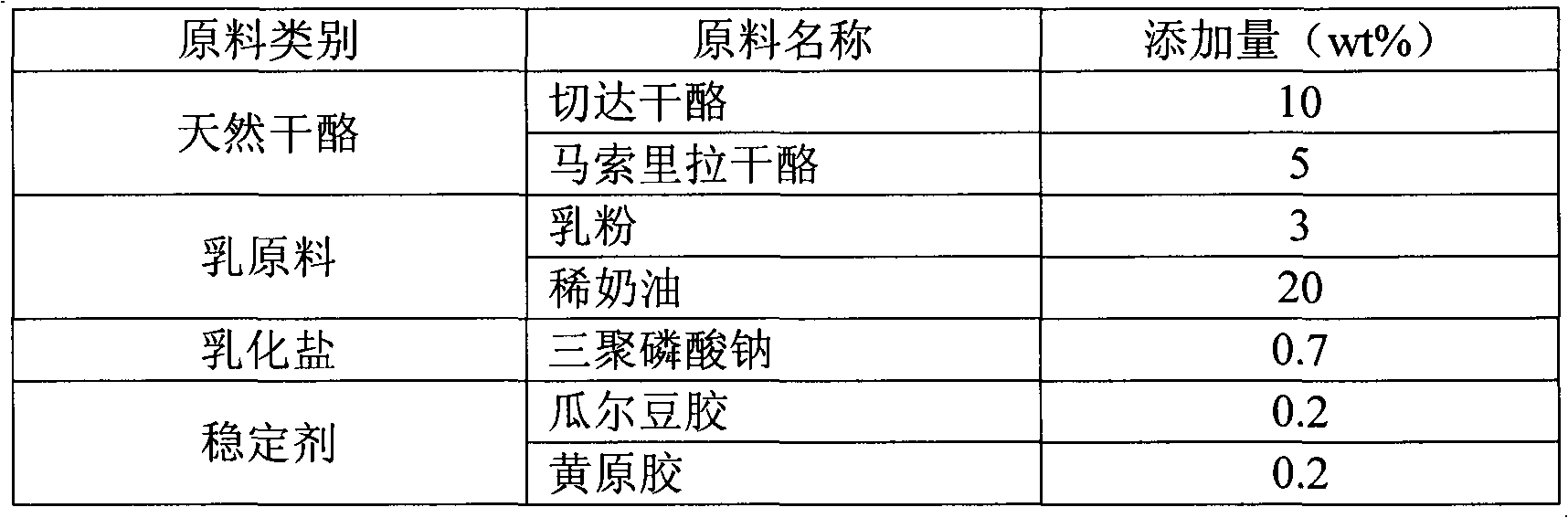

[0032] formula:

[0033]

[0034]

[0035] Preparation:

[0036] (1) Raw material mixing: Divide the natural cheese into small pieces, preferably 3cm×3cm pieces, mix with emulsified salt and some water, and stir evenly; mix other raw materials and the remaining water in another container, and mix well ;

[0037] (2) Sterilization: In order to make the cheese protein fully hydrated and emulsified without affecting the quality of ice cream, the above two parts of raw materials are sterilized separately, and the mixed raw materials containing natural cheese are heated to 90°C and kept at 90°C for 10 minutes for sterilization; the other part of mixed raw materials Sterilize by holding at 75°C for 30 minutes;

[0038] (3) Homogenization: Mix and cool the raw materials to 65°C for two-stage high-pressure homogenization. The first stage of homogenization pressure is 20MPa, and the second stage is 6MPa;

[0039] (4) Aging: reduce the raw material temperature to 4°C and age fo...

Embodiment 2

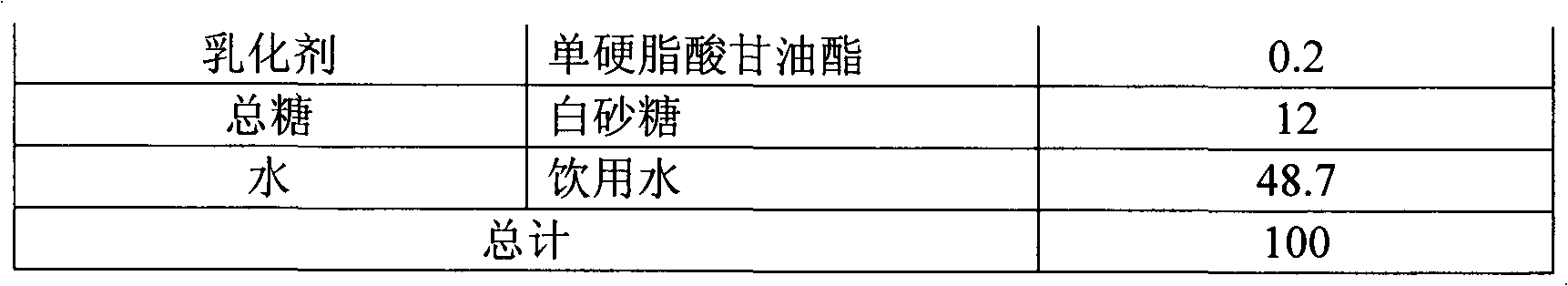

[0044] formula:

[0045]

[0046]

[0047] Preparation:

[0048] (1) Raw material mixing: Divide the natural cheese into small pieces, preferably 3cm×3cm pieces, mix with emulsified salt and some water, and stir evenly; mix other raw materials and the remaining water in another container, and mix well ;

[0049](2) Sterilization: In order to fully hydrate and emulsify the cheese protein without affecting the quality of ice cream, the above two parts of raw materials are sterilized separately, and the mixed raw materials containing natural cheese are heated to 90°C and kept at 86°C for 15 minutes for sterilization; the other part of the mixed raw materials Sterilize by holding at 76°C for 25 minutes;

[0050] (3) Homogenization: mixing and cooling the raw materials to 70°C is to carry out two-level high-pressure homogenization, the first level of homogenization pressure is 15MPa, and the second level is 4MPa;

[0051] (4) Aging: reduce the raw material temperature to 0...

Embodiment 3

[0056] formula:

[0057]

[0058]

[0059] Preparation:

[0060] (1) Raw material mixing: Divide the natural cheese into small pieces, preferably 3cm×3cm pieces, mix with emulsified salt and some water, and stir evenly; mix other raw materials and the remaining water in another container, and mix well ;

[0061] (2) Sterilization: In order to fully hydrate and emulsify the cheese protein without affecting the quality of ice cream, the above two parts of raw materials are sterilized separately, the mixed raw materials containing natural cheese are heated to 90 ° C, and 88 ° C for 13 minutes for sterilization; the other part of the mixed raw materials Sterilize by holding at 79°C for 20 minutes;

[0062] (3) Homogenization: Mix and cool the raw materials to 68°C for two-level high-pressure homogenization, the first level of homogenization pressure is 12MPa, and the second level is 2MPa;

[0063] (4) Aging: reduce the raw material temperature to 2°C and age for 15 hours;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com