Preparation method of agar gel microspheres

An agar gel and microsphere technology, which is applied in the fields of biochemical separation of bioengineering and cells and their protein carriers, can solve the problems of difficulty in realizing industrialized production, complicated operation process and high production cost, and achieves improved uniformity and simple preparation process. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

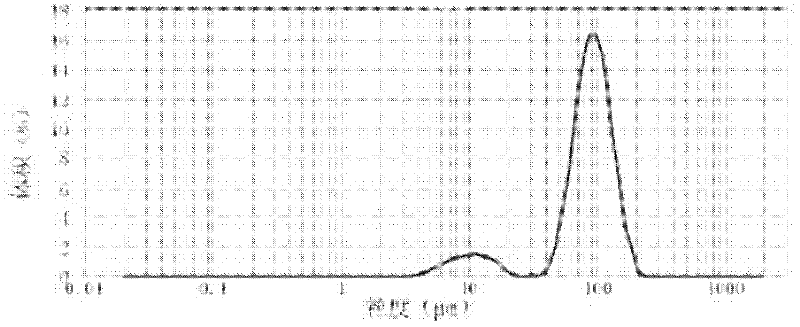

[0034] Prepare 200ml of 10wt% agar aqueous solution by heating, and at a temperature of 70°C, the initial stirring speed is 4500rpm, slowly add the agar aqueous solution to 600ml of 84v% cyclohexane and 16v% Span 85 press Mixed composition of the oil phase. During the emulsification process, adjust and increase the stirring speed so that the final stirring speed is 8000rpm, and continue to stir for 15 minutes, and then cool the emulsion to room temperature by program cooling, and maintain the final stirring speed during the cooling process. Wash the prepared agar gel bare ball with water, 50% ethanol, and water successively, and use OLYMPUS CX41 ( olympus co., ltd. , Japan) optical microscope to observe the product morphology, the results are as follows figure 1 Shown; Adopt MASTERSIZER 2000 laser particle size analyzer (Malvern Instrument Company, UK) to analyze the particle size of product, the result is as follows figure 2 shown. From figure 1 It can be seen from the ...

Embodiment 2

[0039] Prepare the same agar aqueous solution as in Example 1, at a temperature of 72° C., under the condition of 5000 rpm at the initial stirring speed, slowly add the agar aqueous solution to 800 ml of 82v% hexanaphthene and 18v% Span 85 mixture while hot. in the oil phase. During the emulsification process, the stirring speed was adjusted and increased so that the final stirring speed was 9500 rpm, and the stirring was continued for 20 minutes. The obtained product was cooled and washed by the same method as in Example 1, and the product shape was observed and the particle size of the product was analyzed. The results showed that the 10% agar gel bare spheres prepared by this method had a regular spherical shape, and the volume fraction of the gel bare spheres with particle diameters ranging from 30 to 90 μm was 81.2%.

[0040] The cross-linking process of the agar gel bare sphere is different from Example 1 in that the stirring speed is 180rpm, and the Na 2 SO 4 Dosage i...

Embodiment 3

[0043] Prepare the same agar aqueous solution as in Example 1, at a temperature of 68° C., under the condition that the initial stirring speed is 1100 rpm, the agar aqueous solution is slowly added to 400 ml of 86v% hexanaphthene and 14v% Span 85 mixture while hot. in the oil phase. During the emulsification process, the stirring speed was adjusted and increased so that the final stirring speed was 1800rpm, and the stirring was continued for 25 minutes. The obtained product was cooled and washed by the same method as in Example 1, and the product shape was observed and the particle size of the product was analyzed. The results showed that the 10% agar gel bare spheres prepared by this method had a regular spherical shape, and the volume fraction of the gel bare spheres with particle diameters ranging from 450 to 600 μm was 80.5%.

[0044] The cross-linking process of the agar gel bare sphere is different from Example 1 in that the stirring speed is 140rpm, and the Na 2 SO 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com