Preparation method and application of bicontinuous emulsion gel

An emulsion gel, double-continuous technology, applied in the field of preparation of double-continuous emulsion gel, can solve the problems of complex preparation process, high amount of exogenous additives, poor stability, etc., to achieve simple preparation process, environmentally friendly preparation process, The effect of stabilizing gel properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] (1) Structuring of the water phase: Weigh 1 g of xanthan gum and 69 g of deionized water and stir until the xanthan gum is completely dispersed;

[0051] (2) Oil phase structuring: Weigh 1.0g beeswax, 1.0g monoglyceride and 28g rapeseed oil respectively, put monoglyceride, beeswax and rapeseed oil together in a clean and dry container, Stir at 85°C with a magnetic stirrer until the beeswax and monoglycerides are completely dissolved in a total of 30 g of the oil phase;

[0052] (3) Preparation of emulsion gel: disperse the oil gel prepared in step (2) in the xanthan gum aqueous solution prepared in step (1) with a high-speed disperser (10000rpm), cut for 3min; put the mixture in 20 ℃ in a constant temperature box for 24 hours to prepare a bicontinuous emulsion gel.

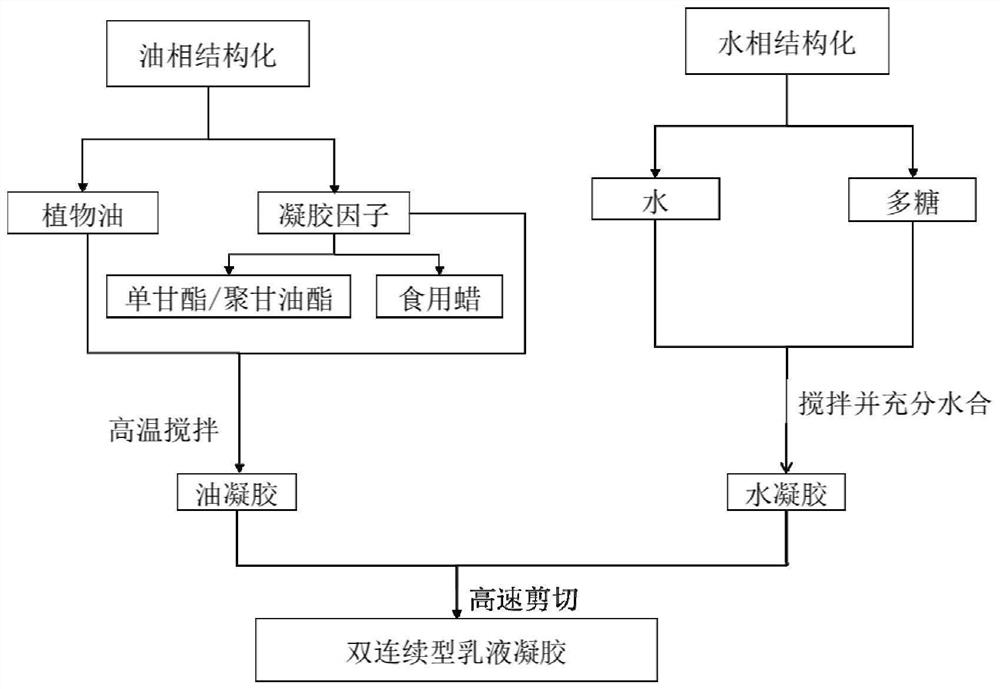

[0053] figure 1 Schematic diagram of the preparation process for the bicontinuous emulsion gel.

Embodiment 2

[0055] (1) Structuring of the water phase: Weigh 1 g of xanthan gum and 69 g of deionized water and stir until the xanthan gum is completely dispersed;

[0056] (2) Oil phase structuring: Weigh 3.0g beeswax, 1.0g monoglyceride and 26g rapeseed oil respectively, put monoglyceride, beeswax and rapeseed oil together in a clean and dry container, Stir at 85°C with a magnetic stirrer until the beeswax and monoglycerides are completely dissolved in a total of 30 g of the oil phase;

[0057] (3) Preparation of emulsion gel: disperse the oil gel prepared in step (2) in the xanthan gum aqueous solution prepared in step (1) with a high-speed disperser (10000rpm), cut for 3min; put the mixture in 20 ℃ in a constant temperature box for 24 hours to prepare a bicontinuous emulsion gel.

Embodiment 3

[0059] (1) Structuring of the water phase: Weigh 1 g of xanthan gum and 69 g of deionized water and stir until the xanthan gum is completely dispersed;

[0060] (2) Oil phase structuring: Weigh 5.0g beeswax, respectively weigh 1.0g monoglyceride and 24g rapeseed oil, put monoglyceride, beeswax and rapeseed oil together in a clean and dry container , stir at 85°C with a magnetic stirrer until the beeswax and monoglycerides are completely dissolved in a total of 30 g of the oil phase;

[0061] (3) Preparation of emulsion gel: disperse the oil gel prepared in step (2) in the xanthan gum aqueous solution prepared in step (1) with a high-speed disperser (10000rpm), cut for 3min; put the mixture in 20 ℃ in a constant temperature box for 24 hours to prepare a bicontinuous emulsion gel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com