Continuous multi-microencapsulation process for improving the stability and storage life of biologically active ingredients

A technology of microencapsulation and active ingredients, applied in microcapsule preparation, microsphere preparation, food science, etc., can solve problems such as lack of optimal preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

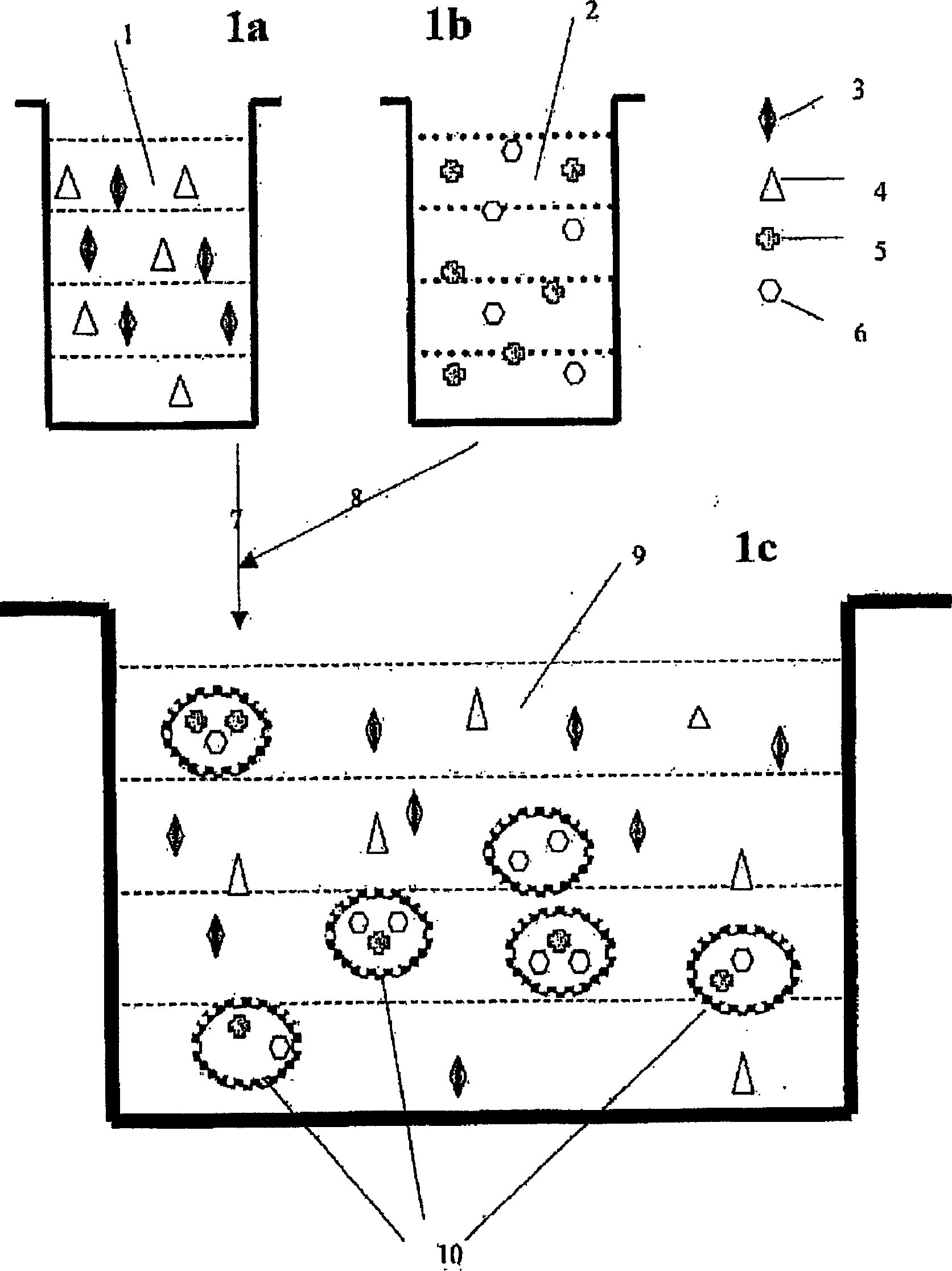

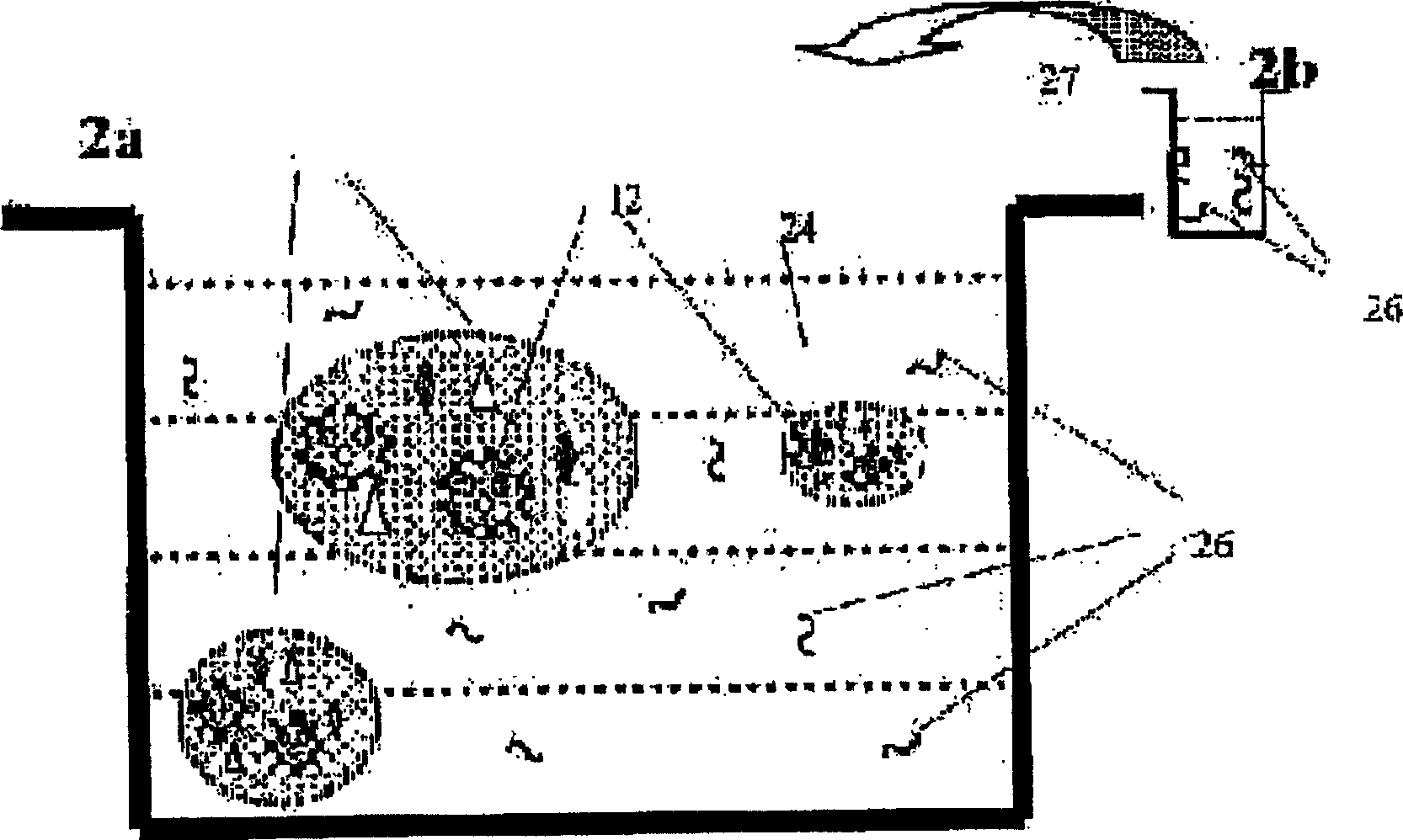

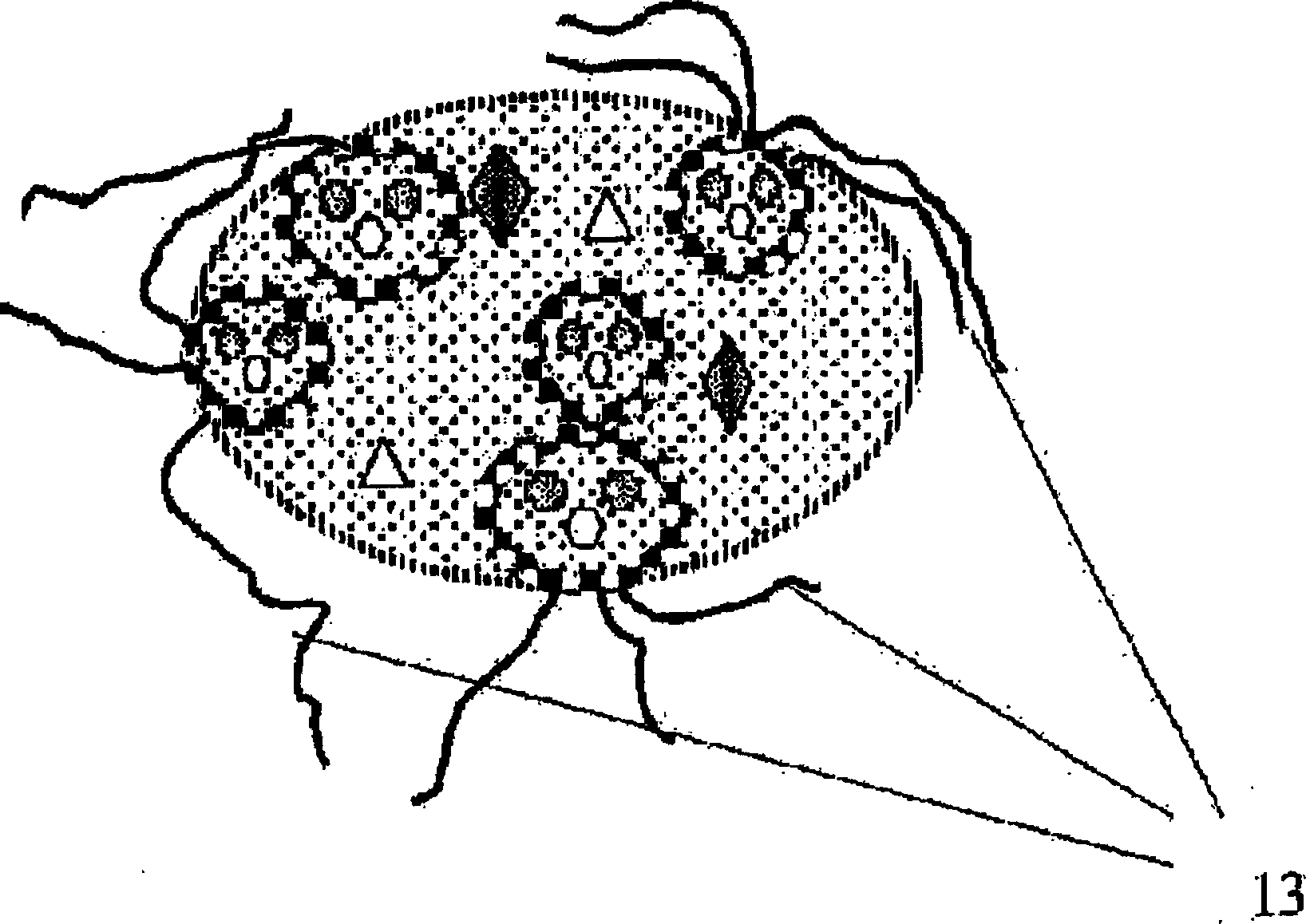

Method used

Image

Examples

Embodiment 1

[0135] In this example we describe the active ingredients used to prepare a formulation suitable for use in orange juice.

[0136] 1.1- Composition

[0137] oil phase [%]

[0138] Flaxoil 25.00

[0139] Emulpur 1.00

[0140] water box

[0141] distilled water * 20.00

[0142] Rosemary Extract 2.80

[0143] Carrot Juice 7.30

[0144] Orlistat (lipase inhibitor) 1.00

[0145] 1.2.- Encapsulating and emulsifying ingredients

[0146] [%]

[0147] alginate solution ** 25.00

[0148] Guar gum (4% in water) 15.40

[0149] Lamegin 2.50

[0150] Keltrol 0.30

[0151] *Add 0.5% CaCl 2 , 0.1% ascorbic acid, 0.08% nipagil [all in water]

[0152] **Alginate solution = 5% Manucol LB in water

[0153] 1.2 Method:

[0154] - Oil phase Weigh in bottle, homogenize in ultrasonic bath

[0155] - Aqueous phase weighed in bottle, homogenized in ultrasonic bath

[0156] -W / O Emulsion Put the oil and...

Embodiment 2 to 11

[0172] In Table 1, we present a series of microencapsulation methods. These microencapsulations were carried out according to the general method described above. The data provided in previous patents were in many cases insufficient to reproduce or obtain the claimed formulations.

[0173] The components tested and the results are listed in Table 1.

[0174] Formulation Components Active ingredients are those described in the oil phase and those in the aqueous phase. The particle size data presented correspond to percentile 50-D(v;0,5)- and percentile 90-D(v;0,9)-.

[0175] We can see the quality of the resulting formulation in the last row. As we can see, small changes in the composition can lead to poorly formulated microencapsulation materials.

Embodiment 12

[0177] In this embodiment, we show the release of microcapsules at a certain pH. The microcapsules break down at stomach pH, while the microcapsules remain intact in yoghurt, which is also acidic (but not as acidic as in the stomach).

[0178] The purpose of this example was to test the release rate of microencapsulated riboflavin (according to the invention) present in prebiotic yoghurt.

[0179] Yoghurt has been prepared (20 kg) in a conventional, manual manner using an "in-house" fermentation culture retained from a previous yoghurt production.

[0180] The composition of the preparation (percentage relative to the total active ingredient) is:

[0181] - riboflavin 100 μg / kg yoghurt (less than 0.1% of total active ingredients)

[0182] -Lactobacillus casei 10% (a solution in water of a culture with 500 colonies per square centimeter)

[0183] -Oat extract 90%

[0184] Formulations were prepared according to the general encapsulation method, using alginate as the cross...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com