Method for preparing water-soluble beta-1,3/1,6-dextran

A dextran and water-soluble technology, which is applied in the field of water-soluble β-1, can solve the problems of low yield and achieve the effects of improving purity and yield, reducing environmental pollution, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1, preparation of water-soluble β-1,3 / 1,6-glucan

[0039] 1. Preparation of water-insoluble β-1,3 / 1,6-glucan

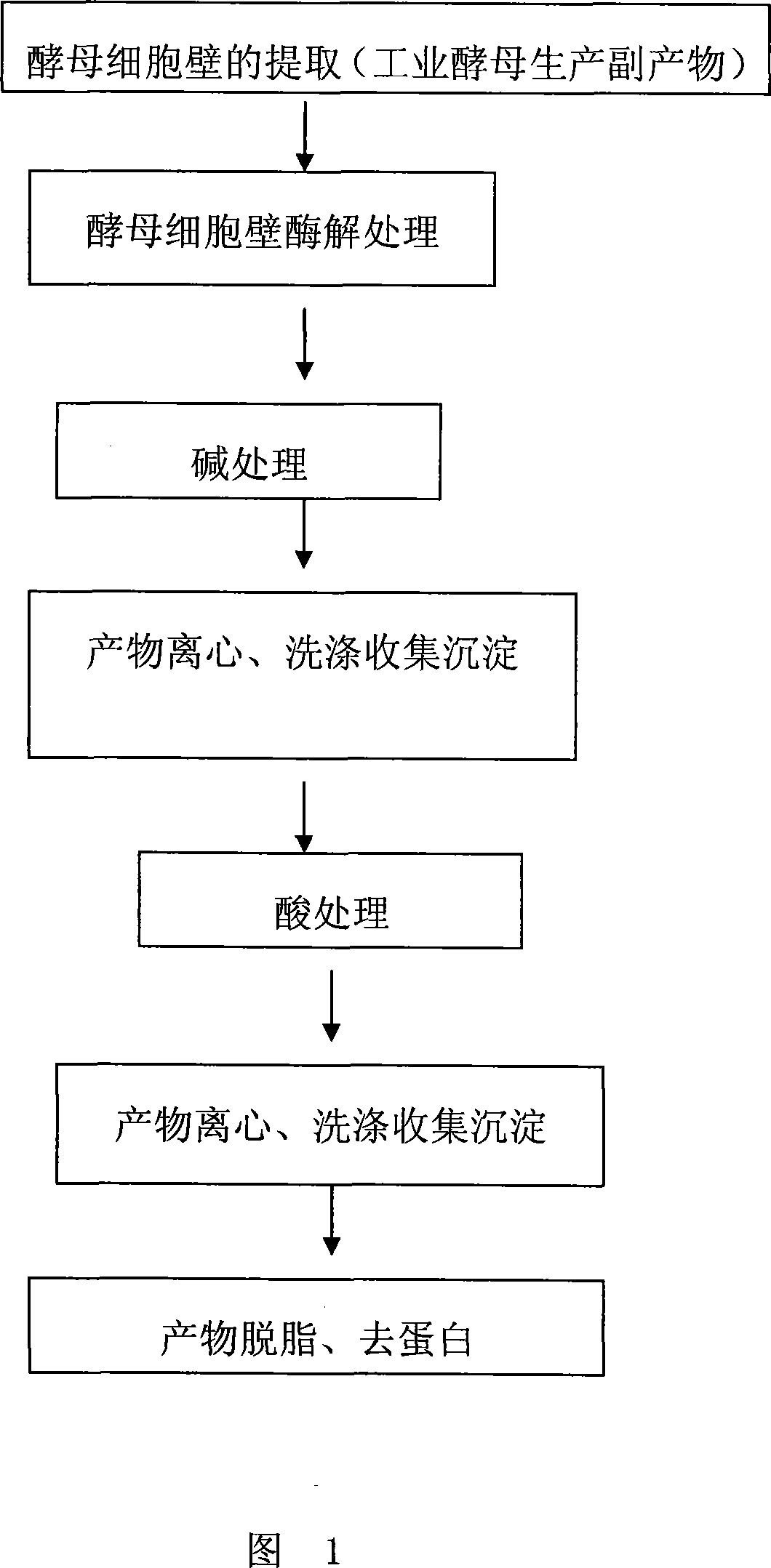

[0040] The production process of water-insoluble β-1,3 / 1,6-glucan is shown in Figure 1, and the specific steps are as follows:

[0041] 1. Enzymatic hydrolysis of yeast cell wall: 100g of yeast cell wall (the product was purchased from Hubei Yichang Angel Yeast Co., Ltd., "Fubon" brand), 100mg (20000U / mg) lysozyme (derived from ovalbumin, Cayman) and 500ml Mix with water (mass ratio: 1000:1:5000), and stir with a constant speed stirrer at a medium speed (Shanghai Specimen Model Factory, Huma brand adjustable speed stirrer, 200-300 rpm) under the condition of 37°C, and the stirring time is After 30 minutes, centrifuge at 3000 rpm (Shanghai Anting Scientific Instrument Factory, DL6000B refrigerated centrifuge, the same below) for 20 minutes to remove the supernatant to obtain 95.3 g of precipitate, which is the product of yeast cell wall enzymatic hyd...

Embodiment 2

[0062] Embodiment 2, preparation of water-soluble β-1,3 / 1,6-glucan

[0063] 1. Preparation of water-insoluble β-1,3 / 1,6-glucan

[0064] The production process of water-insoluble β-1,3 / 1,6-glucan is shown in Figure 1, and the specific steps are as follows:

[0065] 1. Enzymatic hydrolysis of yeast cell walls: Mix 200g of yeast cell walls, 400mg (20000U / mg) lysozyme (derived from ovalbumin, Cayman) and 500ml of water, and use a constant speed stirrer at a medium speed (Shanghai Specimen Model Factory) at 35°C , Huma brand speed-adjustable agitator, 200-300 rpm) stirring, stirring time is 60 minutes, then centrifuged at 3000 rpm (Shanghai Anting Scientific Instrument Factory, DL6000B refrigerated centrifuge) for 25 minutes. Cleared to obtain 191.20g of precipitate, which is the product of yeast cell wall enzymatic hydrolysis.

[0066] 2. Alkali treatment: 191.20 g of the product obtained in step 1 after enzymatic hydrolysis of the yeast cell wall is added to 2000 ml of 0.5 M Na...

Embodiment 3

[0086] Embodiment 3, preparation of water-soluble β-1,3 / 1,6-glucan

[0087] 1. Preparation of water-insoluble β-1,3 / 1,6-glucan

[0088] The production process of water-insoluble β-1,3 / 1,6-glucan is shown in Figure 1, and the specific steps are as follows:

[0089] 1. Enzymatic hydrolysis of yeast cell walls: Mix 200g of yeast cell walls, 600mg (20000U / mg) lysozyme (derived from ovalbumin, Cayman) and 1000ml of water, and use a constant speed stirrer at a medium speed at 40°C (Shanghai Specimen Model Factory) , Puma brand speed-adjustable agitator, 200-300 rpm) stirring, stirring time is 30 minutes, then centrifuged at 3000 rpm (Shanghai Anting Scientific Instrument Factory, DL6000B refrigerated centrifuge) for 20 minutes. Cleared to obtain 190.8g of precipitate, which is the product of yeast cell wall enzymatic hydrolysis.

[0090] 2. Alkali treatment: 190.8 g of the product obtained in step 1 after enzymatic hydrolysis of the yeast cell wall was added to 2000 ml of 1.0 M Na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com