Baked-resistant mooncake stuffing pre-mixed powder and mooncake fruit jam stuffing and preparation methods thereof

A baking-resistant and ready-mixed powder technology, applied in the field of baking, can solve the problems of soft taste of cake skin, increased moisture content, easy to collapse, etc., to improve hardness and plasticity, improve water retention performance, and solve the effect of not easy to shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

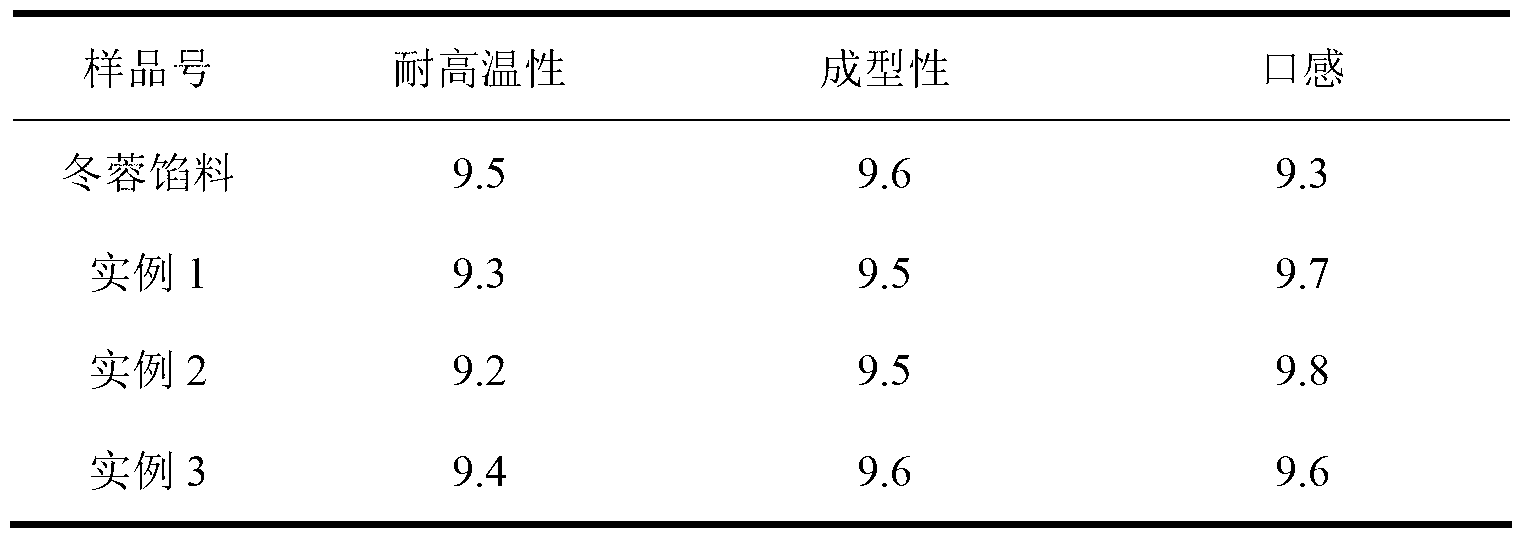

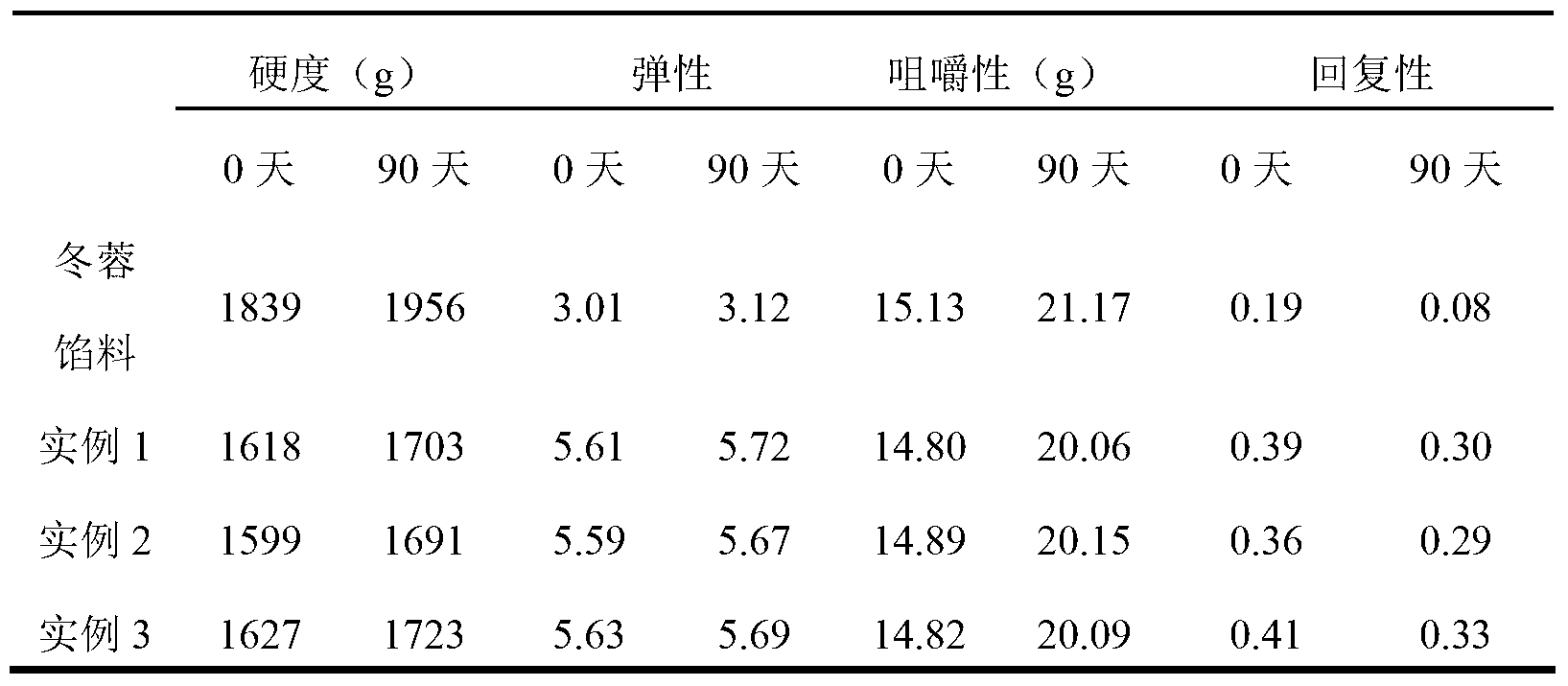

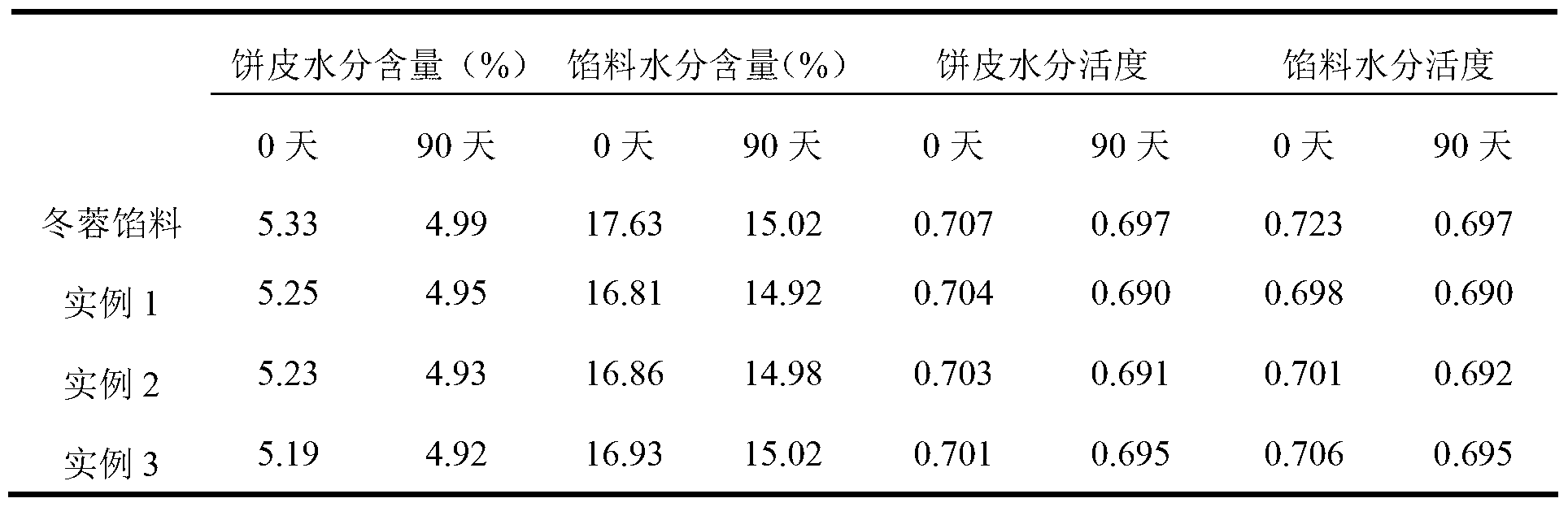

Examples

Embodiment 1

[0044](1) Oxidized hydroxypropyl starch (Foshan Shunde Gaofeng Starch Chemical Co., Ltd., model GHS) 3.65kg, hydroxypropyl distarch phosphate starch (Shanghai Zongtai Industrial Co., Ltd., model PE-05) 2.69kg, Phosphate distarch (Shanghai Zongtai Industrial Co., Ltd., model TGE-20) 3.26kg, sodium carboxymethyl cellulose (0.5% aqueous solution by mass, 25°C, viscosity 900mPa.s) 0.12kg, sodium polyacrylate ( 0.2% by mass aqueous solution, 25°C, viscosity 2000mPa.s) 0.08kg, sucrose fatty acid ester (HLB value 11) 0.11kg, molecularly distilled monoglyceride (mass percentage greater than 92%, HLB value 5.3) 0.09kg, stirred at a speed of 60rpm for 30min in a mixing mixer, passed through a No. CQ20 sieve to obtain 10.00kg of mooncake filling premixed powder and put it into the jacketed pot.

[0045] (2) Put 10.00kg of mooncake filling premixed powder into the jacketed pot, and stir with 7.00kg of refined white sugar at a speed of 60rpm for 10min.

[0046] (3) Add 13kg of purified wa...

Embodiment 2

[0049] (1) Oxidized hydroxypropyl starch (Foshan Shunde Gaofeng Starch Chemical Co., Ltd., model GHS) 3.55kg, hydroxypropyl distarch phosphate starch (Shanghai Zongtai Industrial Co., Ltd., model PE-05) 2.78kg, Phosphate distarch (Shanghai Zongtai Industrial Co., Ltd., model TGE-20) 3.30kg, sodium carboxymethyl cellulose (0.5% aqueous solution by mass, 25°C, viscosity 900mPa.s) 0.11kg, sodium polyacrylate ( 0.2% aqueous solution by mass, 25°C, viscosity 2000mPa.s) 0.07kg, sucrose fatty acid ester (HLB value 11) 0.11kg, molecularly distilled monoglyceride (mass percentage greater than 92%, HLB value 5.3) 0.08kg, stir evenly at a speed of 60rpm in a mixing mixer, pass through a No. CQ20 sieve, and obtain 10.00kg of mooncake filling premixed powder.

[0050] (2) 10.00kg of moon cake filling pre-mixed powder will be put into the jacketed pot, and stirred with 8.00kg of refined white sugar at a speed of 60rpm for 10 minutes.

[0051] (3) Add 15kg of purified water and 0.061kg of p...

Embodiment 3

[0054] (1) Oxidized hydroxypropyl starch (Foshan Shunde Gaofeng Starch Chemical Co., Ltd., model GHS) 3.47kg, hydroxypropyl distarch phosphate starch (Shanghai Zongtai Industrial Co., Ltd., model PE-05) 2.80kg, Phosphate distarch (Shanghai Zongtai Industrial Co., Ltd., model TGE-20) 3.30kg, sodium carboxymethyl cellulose (0.5% aqueous solution by mass, 25°C, viscosity 900mPa.s) 0.12kg, sodium polyacrylate ( 0.2% aqueous solution by mass, 25°C, viscosity 2000mPa.s) 0.10kg, sucrose fatty acid ester (HLB value 11) 0.11kg, molecularly distilled monoglyceride (mass percentage greater than 92%, HLB value 5.3) 0.10kg, stir evenly at a speed of 60rpm in a mixing mixer, pass through a No. CQ20 sieve, and obtain 10.00kg of mooncake filling premixed powder.

[0055] (2) Put 10.00kg of mooncake filling premixed powder into the jacketed pot, and stir with 9.00kg of refined white sugar at a speed of 60rpm for 10 minutes.

[0056] (3) Add 11kg of purified water and 0.055kg of potassium sorb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com